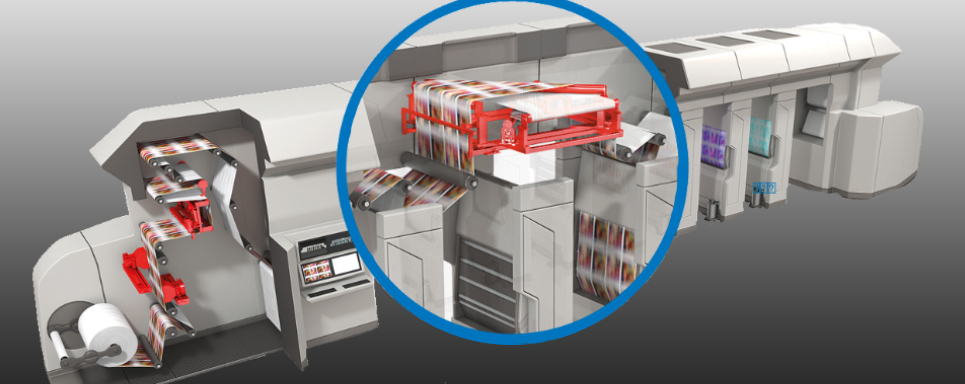

In production processes with moving webs, there is typically an unwinder at the machine infeed and a rewinder at the exit. During unwinding, the winding station is moved via a linear drive to feed the web in the desired position. On the other hand, during rewinding, the winding station follows the constantly changing web position via a linear drive to achieve an evenly wound reel.

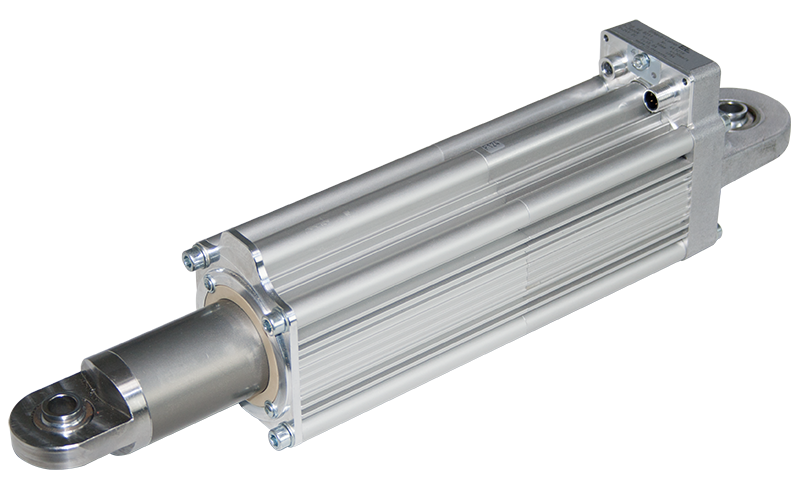

Due to their technical features, the linear actuating drives from Erhardt+Leimer fully meet the customer’s requirements for improved quality, higher productivity, less waste, and freedom from maintenance. The brushless drive technology is wear-free, and due to the integrated control software, the actuating force and actuating travel of the linear actuating drives can be adjusted continuously. An integrated Multiturn encoder for absolute position detection holds the position of the linear drive even in cases of voltage failure. By the use of a gearless BLDC motor the E+L actuating drives guarantee the highest control accuracy and control dynamics.

The integrated control electronics of the AG 91/93 series from E+L offers genuine added value for the customer when it comes to integrating the E+L components into his machine concept. Cabling of the components has been reduced to a minimum so that considerably less space is required in the control cabinet, thereby saving high costs and resources for the customer when designing his machine.

Commissioning of the E+L components is very easy via web-based management, i. e. using a standard web browser – without any need for dedicated software. With an integrated Ethernet interface as a standard, the E+L linear actuating drives are perfectly equipped for the use in the era of industry 4.0.

https://www.erhardt-leimer.com/product/sensor-positioning-vs-80/

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/user_upload/_SMARTSCAN-EL-Inspection-Mitte_800PX.jpg)