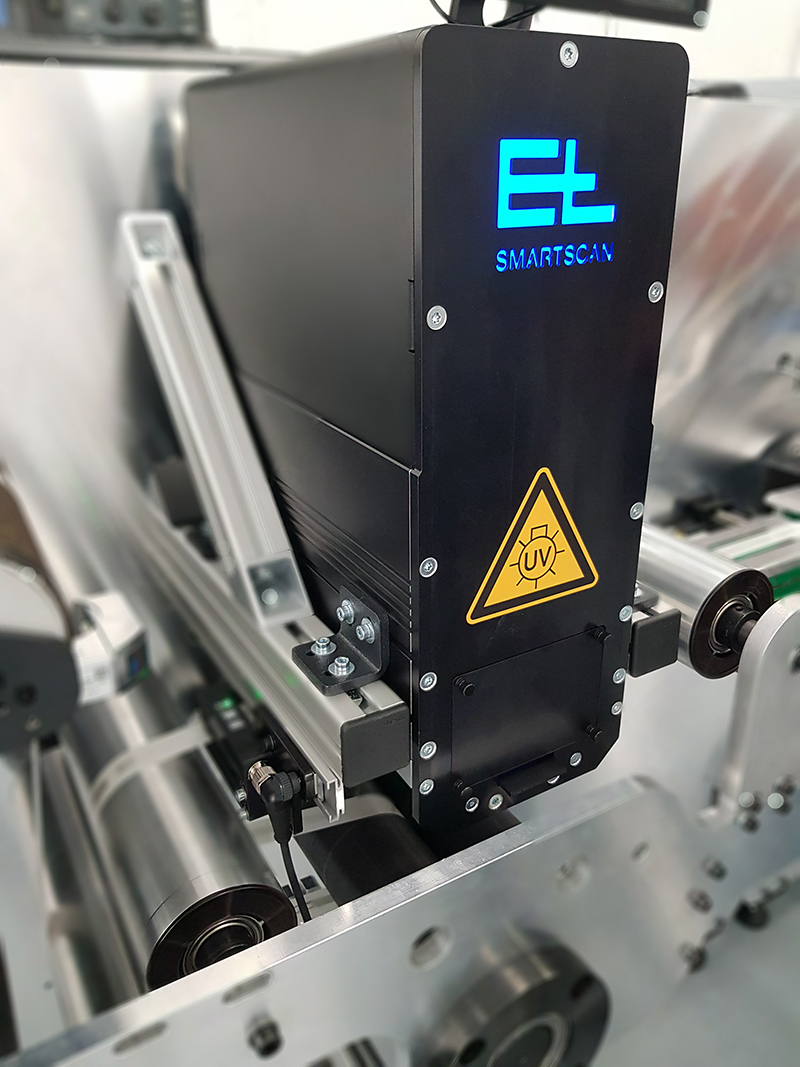

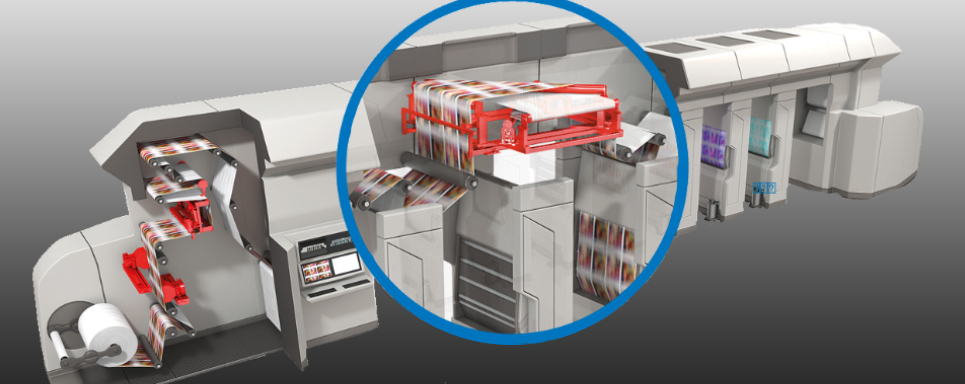

100% inspection systems are becoming ever more important due to the high requirements in the labels market. Only they can guarantee quality control over the entire web width for the detection of typical defects in label processing - from the beginning of the web through to the end. With SMARTSCAN, Erhardt+Leimer is offering an innovative solution that even goes beyond 100%. With 200% inspection SMARTSCAN is unique in the market.

Moreover, SMARTSCAN can be used not only for quality control in the labels market, but also for the checking of other printing applications, such as in packaging printing.

The new generation of our inspection system offers even more advantages and contributes to a high degree to optimize your production process.

SMARTSCAN Generation II

- More compact dimensions

- New inspection widths

- Simplified integration

- No more external control cabinet

- Optimized illumination concept

- Integrated reflection module and exchangeable background panel

- Higher web speed

- Improved defect algorithms

- Eye-catching design

Revolutionary operating concept

The unique, automated “one-click” operating concept means that no time is wasted on operating the system and the users can focus on their actual work. There is no need for time-wasting training courses.

Typical application areas

- Printed and unprinted materials

- Labels and packaging made of paper and film (opaque, semi-transparent, transparent, clear-on-clear)

- Reflective materials

- Metallized materials like aluminum (with special hole detection)

- UV inspection

- RFID inspection

- Code reading and code monitoring

Learn more about our 200% inspection system SMARTSCAN

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/user_upload/_SMARTSCAN-EL-Inspection-Mitte_800PX.jpg)