In all production processes, it is ultimately necessary to ensure the quality of materials and immediately identify any optimization potential in manufacturing. The ELTIM system from Erhardt+Leimer allows precise determination of the material distribution and the material consumption of the web on the basis of weight. This enables customers to optimize energy consumption and save costs by optimizing the material usage.

The ELTIM system from Erhardt+Leimer (Link: https://bit.ly/41ne0Hz) can be used in various industries such as Converting, Extrusion, Calenders and others more.

High accuracy basis weight measurement

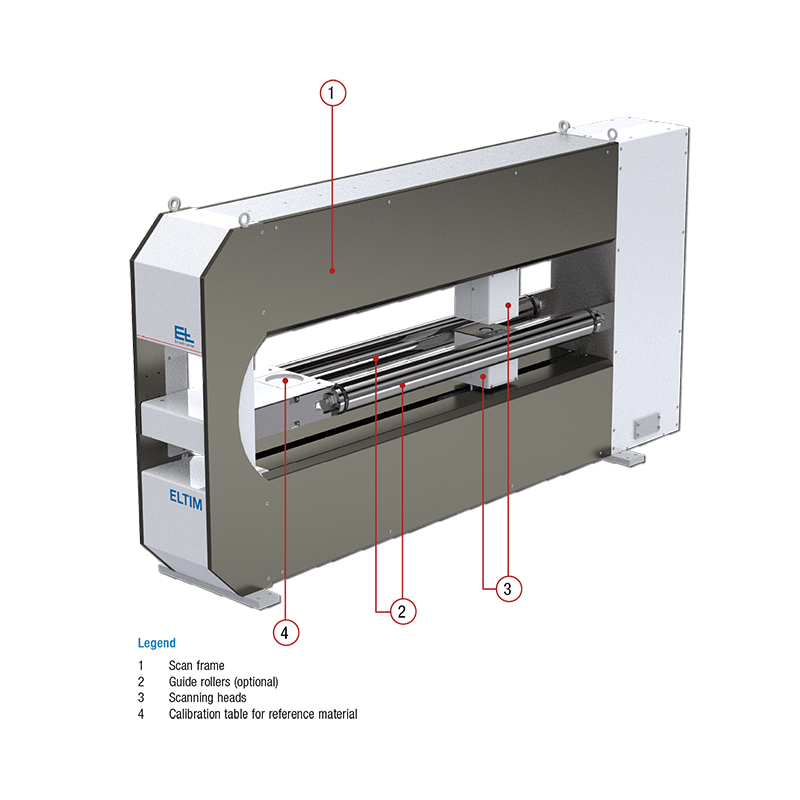

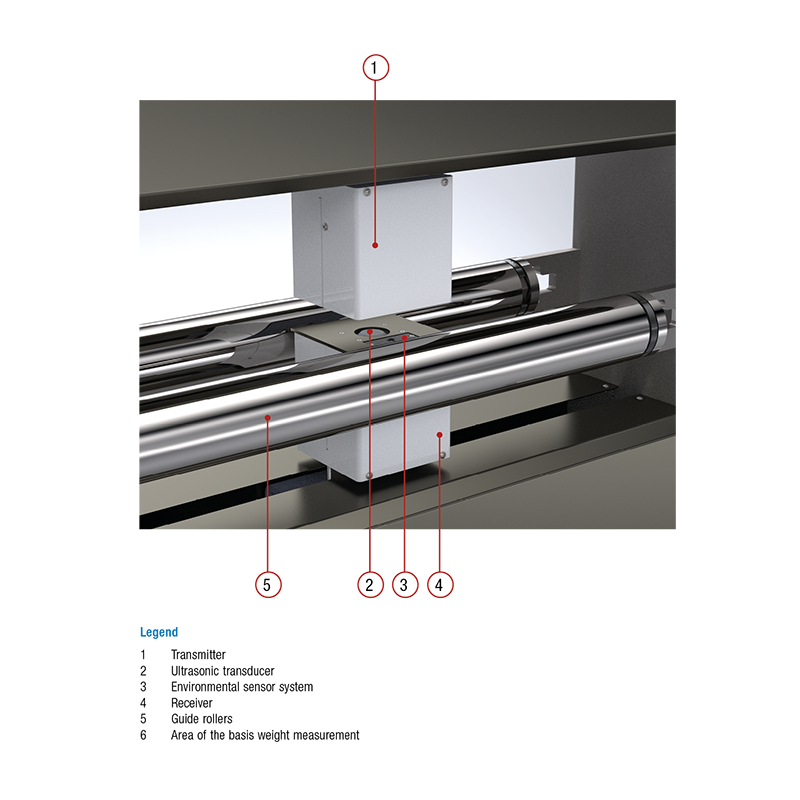

ELTIM is an ultrasound-based, radiation-free sensor for non-contact determination of the basis weight of materials such as plastic foils and coatings. It offers highest accuracy especially for thin material with high frequency and a small detection area. In addition, special sensors record data such as ambient and material temperature, atmospheric humidity, and air pressure.

Advantages of the system

- No danger from radiometric radiation or X-rays

- Compact system, easy to integrate in existing machines

- Small detection area for highest accuracy

- Sensors for detection of interfering ambient conditions

- Precise time log synchronization

- Insensitive to fluctuations in the web height

- No interference even with color fluctuations

- Maintenance-free transmitter and scanner

- Machine interfaces for every customer control

- Extensive analysis software such as 3D surface profile display

Ultrasonic measuring process

In this process, the transmission absorption of an ultrasonic wave energizing a material web is determined without contact using an ultrasonic transmitter and an ultrasonic receiver. The basis weight is calculated from the absorption and the calibration factor.

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/user_upload/_SMARTSCAN-EL-Inspection-Mitte_800PX.jpg)