Any manufacturer working with moving web production knows the importance of web tension measurement and control. Or so we thought. The reality is that today's manufacturers and users of machines for processing web-type materials are faced with ever-increasing demands: to make production processes even faster and more precise, to improve the quality of the finished product, and to reduce personnel, waste and, above all, downtime to a minimum. In order to achieve all these goals, manufacturers are looking for every possible way to optimize their processes, but they tend to overlook one very important factor: their web tension.

What is the problem?

Typically, web-type materials are fed from a roll to the machine, finished and then rewound. At each of those stages, web tension errors may occur. For example, if the material is unwound with too little tension, it will cause slacking in front of the drive unit. Too much tension, on the other hand, can cause longitudinal creasing and web deformation. The same applies to rewinding. Too little tension can cause roll telescoping, while too much tension can damage the inner windings. All these problems lead to malfunctions and quality impairments in the final product. The elimination of these sources of error and ensuring a constant web tension during the production process is the task of Erhardt+Leimer’s ELTENS web tension control system.

Precise measurements are key!

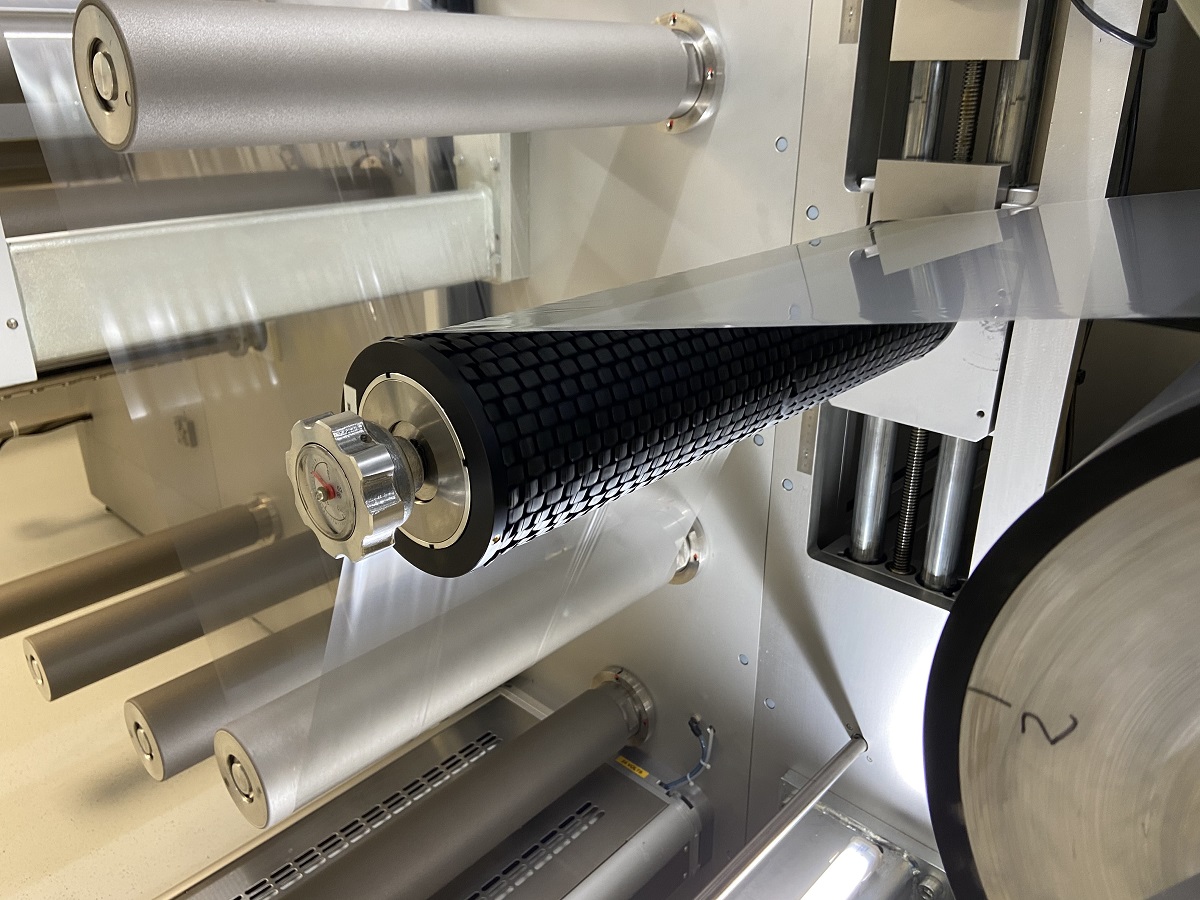

At the heart of the ELTENS system are a wide variety of load cells. Starting with flange load cells, which can be mounted on one or both sides of a roller and are suitable for many different types of production and environments. If you prefer a combined roller and load cell solution, our all-in-one sensor rollers can provide it. And if your production requires a load cell that can be easily mounted on machine platforms or on the side of a machine wall, our block load cells will do the trick. They offer significant advantages, especially in the converting industry, where the excellent accessibility of the pedestal bearings allows for easy roller replacement. Regardless of your choice, all load cells reliably measure web tension, have minimal to no signal drift, and have high linearity of the measuring elements. In addition, they all have overload protection for 10 to 20 times the nominal measuring force and accuracy classes up to 0.5.

![[Translate to English:]](/fileadmin/_processed_/b/4/csm_EL_ELTENS_Control_loop_1200x435_4cef97ed15.png)

![[Translate to English:]](/fileadmin/redakteur/Kunden/Erhardt___Leimer/2024-02-12/MY_E_L_Footer.png)