The machinery and plant engineering industry is currently facing very specific technical challenges: the need for modernization, simplification and standardization. At the same time, extreme flexibility and agility, i.e. rapid implementation and a high degree of adaptability to constantly changing requirements, are required. These conflicting demands, coupled with the tendency for engineering departments to be overloaded, often lead to conflicting objectives during implementation.

As the prime mover of every production process, drive technology plays a central role in reconciling the technical conditions with the daily reality of production. It is therefore high time to find answers and solutions for a fast, simple and safe adaptation of drive units. Erhardt+Leimer meets this challenge with its state-of-the-art EL.MOTION drive concept and sets new standards for Industry 4.0.

The EL.MOTION BLDC drive units

The EL.MOTION drive units from Erhardt+Leimer comprises a wide range of gearless synchronous drives. The product portfolio includes linear and rotary drive units. The groundbreaking innovation of EL.MOTION lies in the fact that the previous BLDC machines in this performance class can now be replaced by synchronous machines. This makes it possible to achieve the high dynamics and control accuracy typical for gearless drives in a much more compact design. Despite the small form factor, the system also features fully integrated power electronics with a fail-safe encoder system.

The motors can be controlled via web-based management using any browser. The built-in Ethernet interface with Ethernet UDP, Ethernet/IP and Profinet support allows all drives to be integrated into existing production processes, thus making them ideal for Industry 4.0 concepts.

Linear drive units

The linear drive units AG 90, AG 91, AG 93 and AG 96 are synchronous motors with high control accuracy and control dynamics. The nominal actuating forces of the motors range from 400 to 5500 N at feed rates of up to 60 mm/s. The linear drive units are particularly suitable for long-term applications and are used, for example, on running webs for web control at unwind and rewind stations.

Rotary drive units

The AD 11, AD 12 and AD 14 rotary drive units are synchronous machines with high power density. The motors achieve a torque of 1 - 4 Nm at speeds between 1000 and 225 rpm in a compact package. This allows gearless operation in many applications. High axial loads are also easily accommodated thanks to the protection provided by a double-row angular contact ball bearing. This means that the drives can be connected directly to a machine without a coupling, enabling them to be easily integrated into existing production lines.

STO – safe torque off

The STO (safe torque off) safety function according to EN 61800-5-2 is an optional addition to Erhardt+Leimer drive units. It is an in-drive safety function that shuts down the motor torque by interrupting the control pulses.

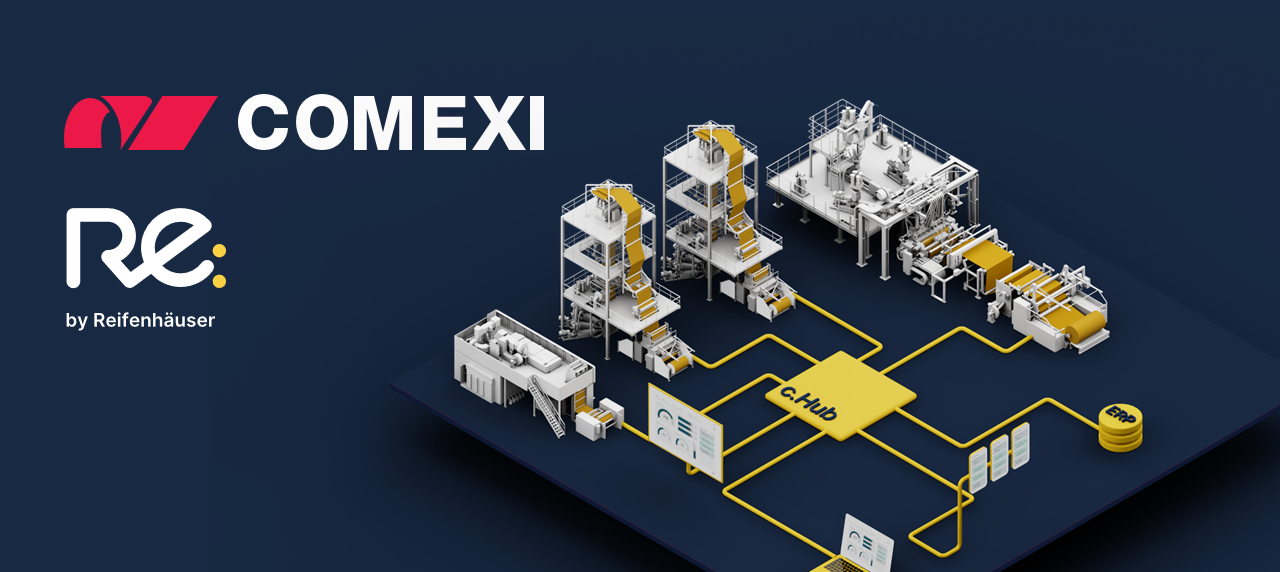

EL.MOTION with EL.NET for a connected production

As with many other products, a growing number of EL.MOTION drive units can use the EL.NET network technology from Erhardt+Leimer. EL.NET makes it possible to display and address many components within a production process in one standardized network. This means that data from running webs can be easily connected across devices and can be monitored and analyzed in real time. Increased productivity, consistent production quality, and new automation options are just a few of the many benefits EL.NET has to offer.