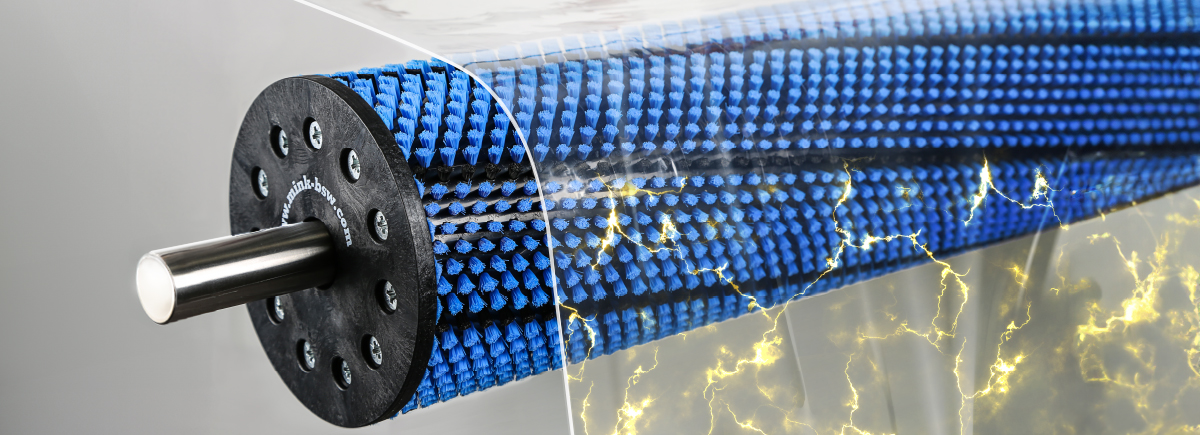

Mink spreader rollers (BSW) are characterised by an excellent spreading effect compared to conventional systems. Crease-free smoothing right up to the edge of the web, without marks or streaks is reliably guaranteed by the Mink BSW technology. The rollers do not require a separate drive and are virtually wear- and maintenance-free. Easy and low cost installation is also possible in critical system areas.

Film thicknesses from 5mµ, web widths of up to 8 meters and very high running speeds, thanks to dynamic balancing, are no problem for Mink spreader technology. The use of our spreader roller offers a threefold advantage: Reliable smoothing, precise creation of slits and safe discharge of electrostatic charges from the web - all in a one process. Our spreader rollers are setting new standards by reliably eliminating creasing thanks to their unique bristle technology whilst also ensuring effective electrostatic dissipation thanks to the conductive bristles. This is crucial to maintain the quality of your products and avoid possible damage from uncontrolled electrostatic discharge.

With a high contact resistance of 103, our spreader rollers offer reliable discharging of different fabric webs, resulting in fewer rejects and additional optimisation of your production processes.

Visit our stand at techtextil to find out more about the benefits of our Mink spreader rollers and take your web handling to a new level. We are looking forward to advising you personally in Hall 12, Stand D25!