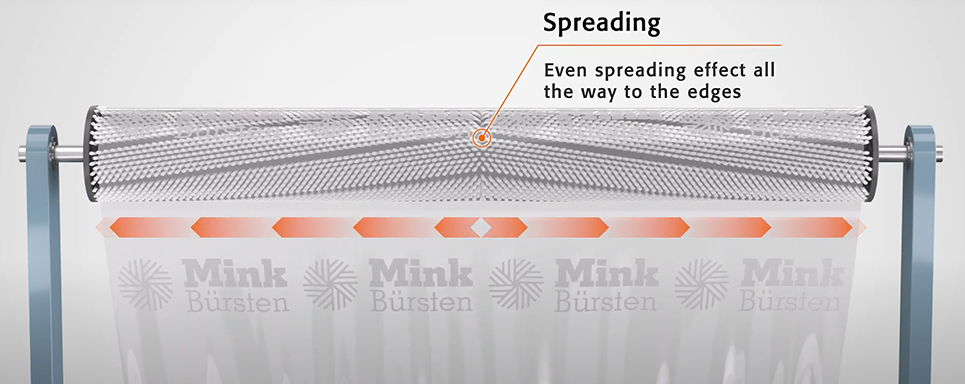

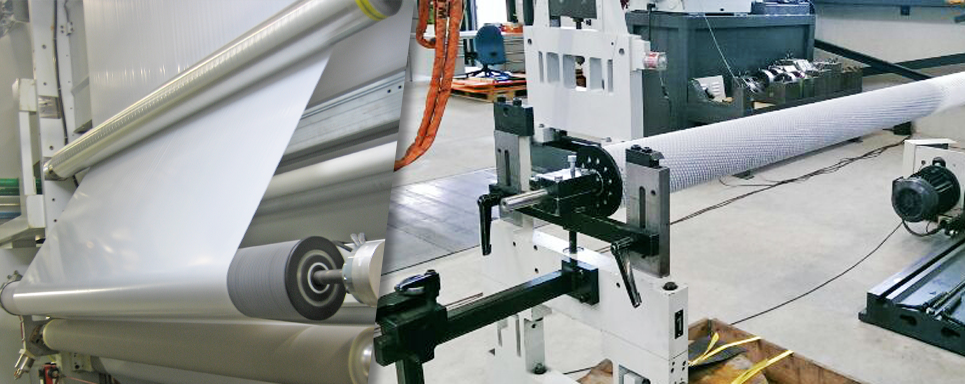

Mink spreader rollers flatten films in manufacturing and processing, thus ensuring crease-free production.

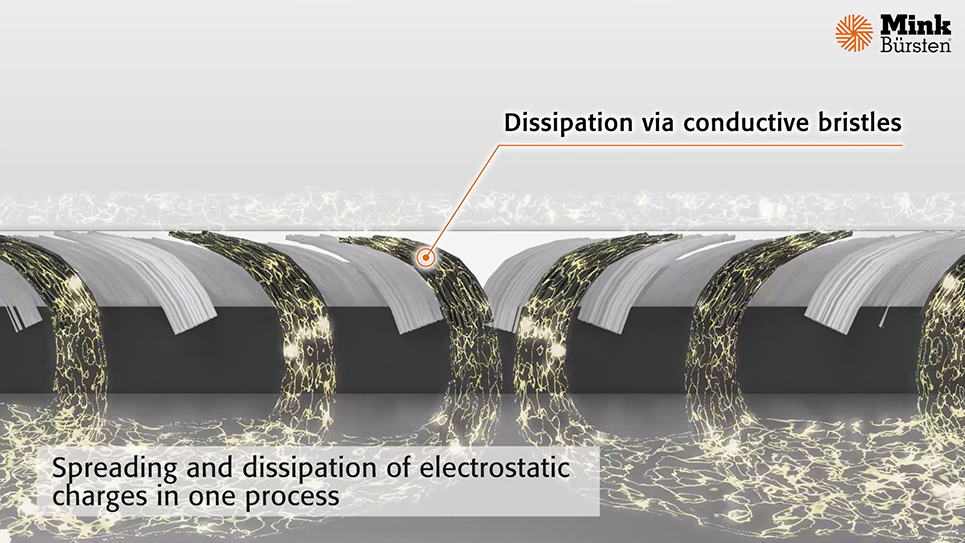

In addition to undesirable creases, electrostatic charges on the film are often a production problem. Undesirable effects can already occur from a charge as low as 10 to 15 kV. In practice, however, the charges are often significantly higher, which leads to a wide variety of interference problems. From the risk of fire and explosion to electric shocks, from uncontrolled discharges to the magnetic attraction of dust and dirt - the consequences can be manifold. The films sticking to surfaces, the flow of web is disturbed and thus the machines have to run more slowly. Even when wound up, the charged films remain electrically charged for months, which leads to further problems in the subsequent processes.

Thanks to innovative bristle technology, Mink spreader rollers not only eliminate creases, but also reliably remove electrostatic charges. The conductive bristles absorb the charges and continuously discharge them via the grounded machine frame. The result is smooth processes and a high net output from the production machinery.

Mink spreader rollers are used wherever top quality and performance are required.