Creasing and electrostatic charges are among the most common problems in the production and processing of fabric webs. These so-called "silent profit eaters" lead to reduced production output, higher reject rates, a reduction in quality, and longer set-up times, all of which have a negative impact on the profitability of any production line.

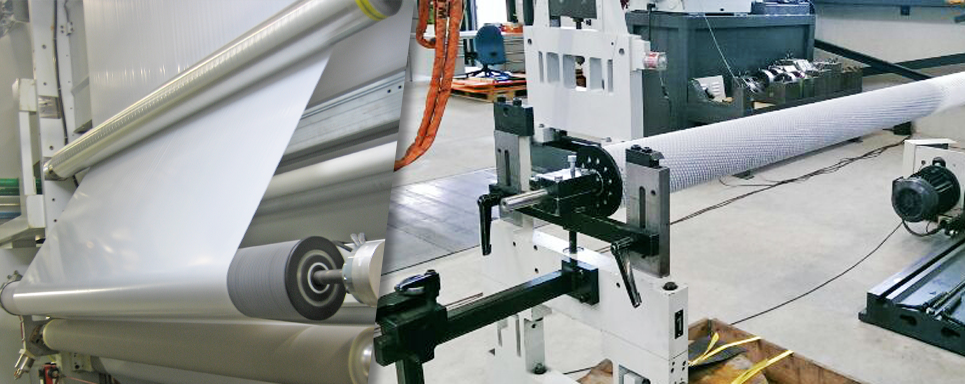

The Mink spreader roller (BSW) offers an effective solution to these undesirable effects.

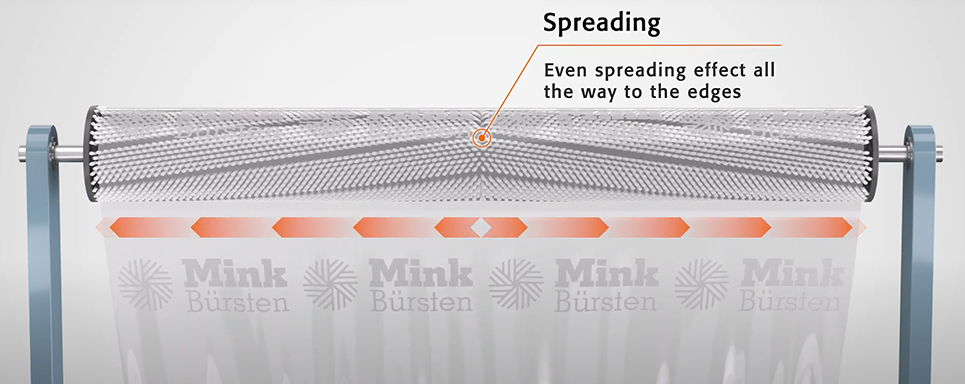

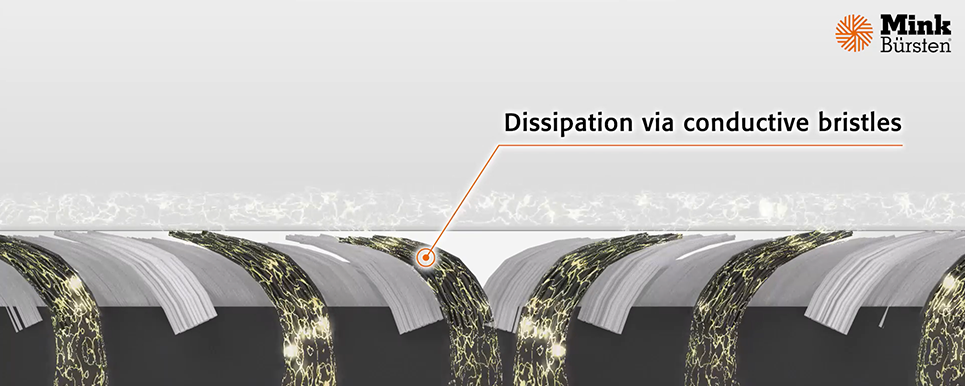

Due to the special arrangement of the bristle bundles on the web spreader roller and the adaptable – as well as optionally conductive - bristles, an even distribution of force is achieved from the centre to the edge of the web. Creases are removed without leaving marks or damaging the web, while electrostatic charges are reliably discharged. Even sensitive materials such as metallised films, hygienic films or separator films are gently stretched to the edge of the web.

The Mink spreader roller is used wherever precision, efficiency and perfect quality are required.

See for yourself and come and see us from 23 to 26 May in Munich at FESPA, Europe's leading trade fair for screen, digital, large-format and textile printing, in Hall B2, Stand C22.