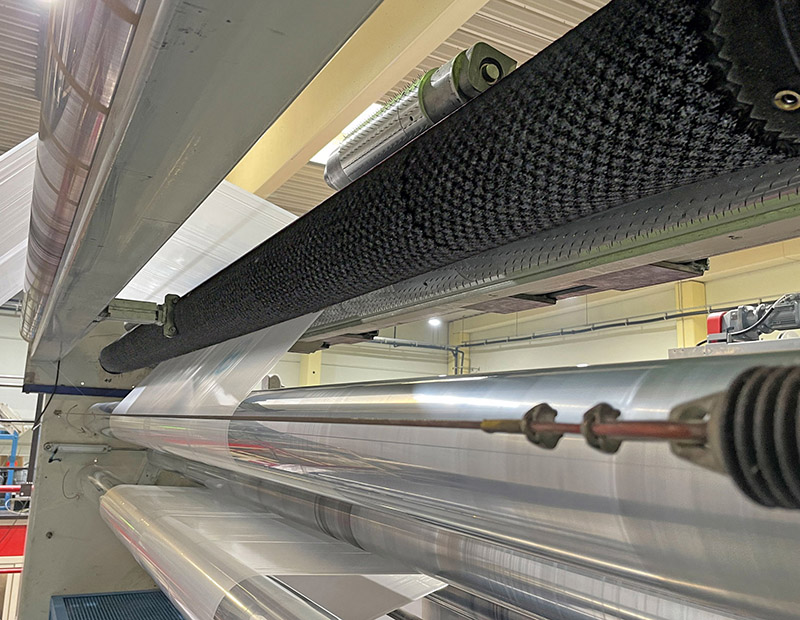

Creases and electrostatic charge are common problems encountered in the manufacture and processing of web materials. Whether textiles, paper, films or non-woven fabrics, almost all materials crease under tension and also become electrostatically charged during processing. This causes disruptions in material transport, contaminates the processed material webs and results in production stops.

In order to avoid such quality problems during processing, the web must be stretched and straightened in a defined manner before the critical processes, and electrostatic charging must be prevented.

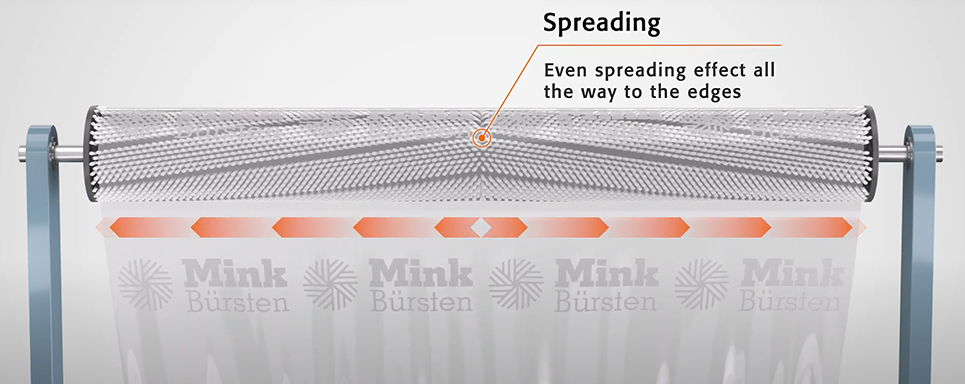

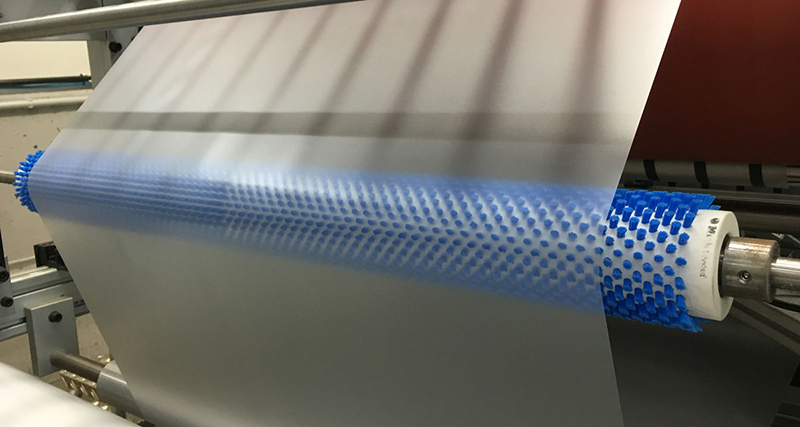

The Mink web spreader roller (BSW) works with the latest bristle technology and opens up completely new possibilities. The spreading of the web is achieved through the flexibility of the individual bristle bundles. These bundles are angled outwards from the centre of the web spreader roller and bend slightly outwards when they come into contact with the web. This bristle movement creates a gentle spreading effect which is continuously repeated as the web spreader roller rotates. The result is a gentle and effective spreading all the way to the edge of the web and an absolutely crease-free material transport.

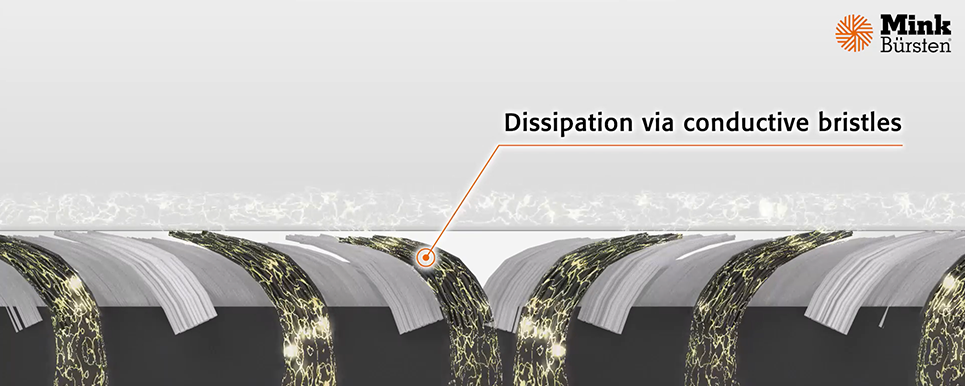

To prevent electrostatic charging, the brushes can be combined with electrically conductive bristle materials. Electrostatic charges are continuously discharged from the web via the tips of the conductive bristles. This prevents a magnetic effect and the associated production problems whilst ensuring that the system operator does not receive any electric shocks from uncontrolled electrical discharges.

The use of Mink web spreader rollers therefore reliably ensures higher system productivity, lower reject rates and hence improves the quality of the end product.

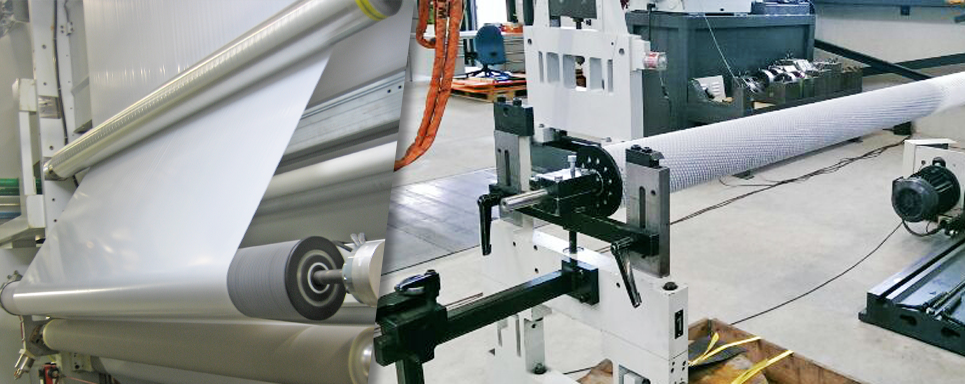

Due to the extremely durable bristle materials, the Mink web spreader roller works almost wear-free and can be cleaned very easily, even when heavily soiled. Typically, the web spreader roller is installed before all critical processes of the machine. Existing deflection rollers can simply be replaced with a Mink web spreader roller which will be supplied installation-ready.

Mink web spreader rolls:

- Gentle spreading of all materials up to the edge of the web

- Dissipation of electrostatic charge via conductive bristle tips

- Virtually wear-free

- Brush elements can be replaced individually - modular design

- Available with FDA certificate

- Economical