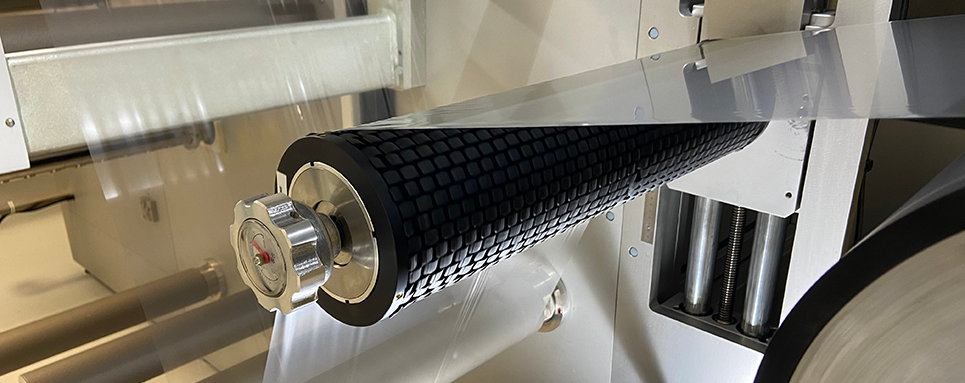

Nowadays, packaging films are a very complex composite of various components that are extruded in different layers. In production lines, the EcoStretchRoll helps to guide materials through the line without wrinkles, thus avoiding rejects and downtimes.

Films are often subjected to corona pre-treatment during the production process so that they can then be printed, laminated, metallised or coated. This is necessary because untreated films have a non-polar, electrically insulating and water-repellent surface. The corona pre-treatment exposes the film web to a high-voltage electrical discharge and thus improves its wettability. Subsequently, packaging films, for example, can be printed with the corresponding labels.

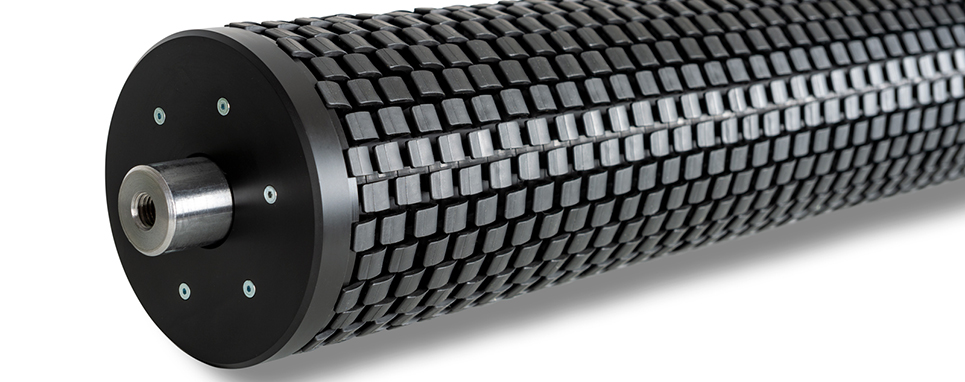

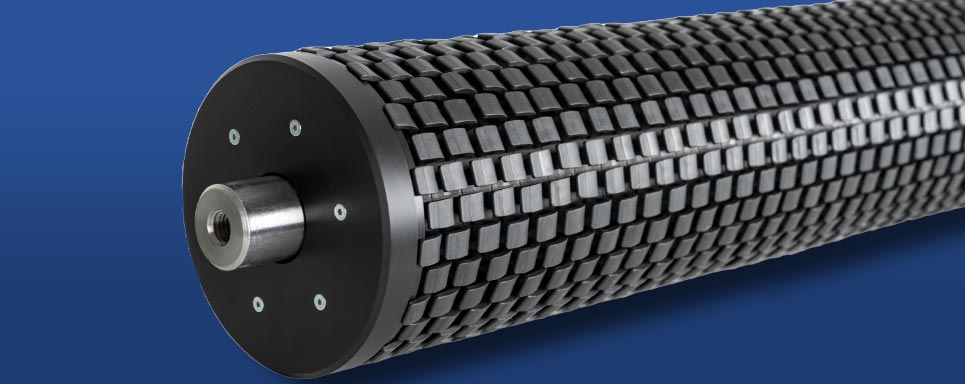

Since thin, sensitive films must be fed into the pretreatment as wrinkle-free as possible, the use of the EcoStretchRoll as the last roller before the treatment has proven its worth. The EcoStretchRoll convinces with its effective wide stretching even with the thinnest materials < 5 µm layer thickness. It is used like an idler roller, without adjustment or external drive.

Thanks to individual independently operating spreading elements, effective spreading is possible without any marking of the surface and, at the same time, shines with a long service life due to its ozone resistance.

The advantages of the EcoStretchRoll at a glance

- even spreads media with layer thicknesses < 5 µm

- available in diameters of 60 mm, 110 mm, 130 mm, 150 mm (roller core 40, 80, 100 or 120 mm)

- No non-functional middle section

- wrap angle of 10 - 180° possible

- Gentle, mark-free and effective spreading

- spreads as soon as there is spreading potential - even with low web tension

- No external drive required; the spreader roller is driven by the web

- universally applicable, e.g. as an alternative to an idler roller

- ozone-resistant

- can be used for multiple applications