In industry, the active use of adhesives has already been standard for many years. Connections that were previously realised by mechanical fuses are increasingly being replaced by double-sided adhesive solutions. The advantages of adhesive technology are accuracy, ease of processing and clean, safe application.

In small installation spaces, double-sided adhesive films are being used more and more. In smartphones, for example. These are getting thinner from year to year. A current smartphone, for example, now measures only 7.3 mm. In order to precisely install all components in the housing of such a high-tech device, intelligent adhesive solutions are being used more and more frequently.

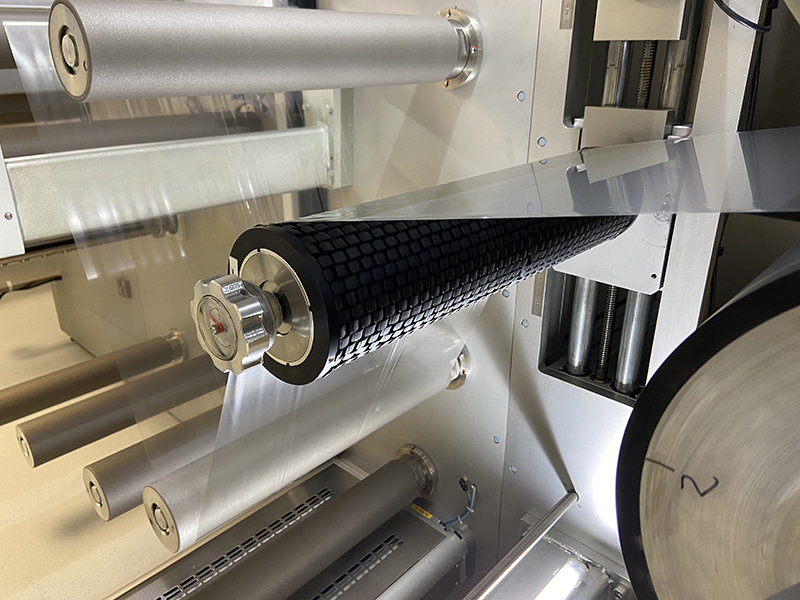

For this purpose, very thin films are used that are coated with adhesives and then laminated onto a carrier material. In a current application, our customer is coating a biaxially stretched film with a thickness of 4 μm. Previous spreader rollers could not completely prevent wrinkling with this type of film.

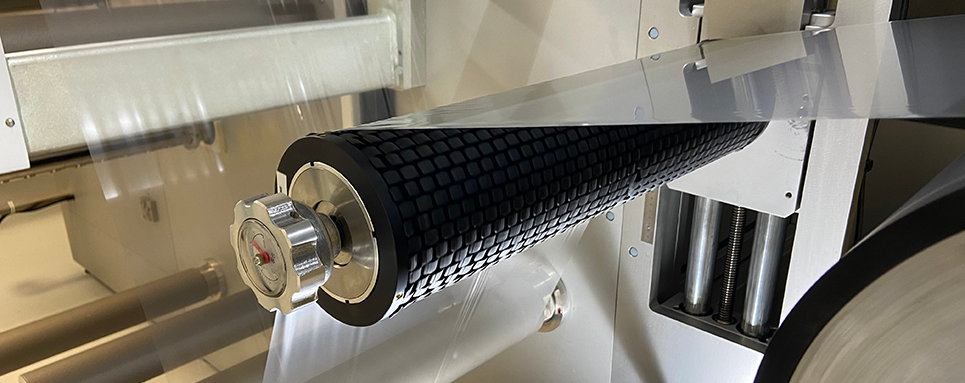

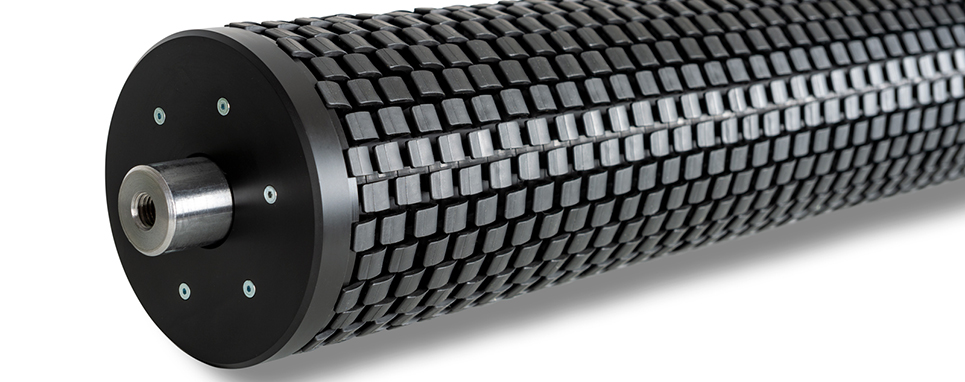

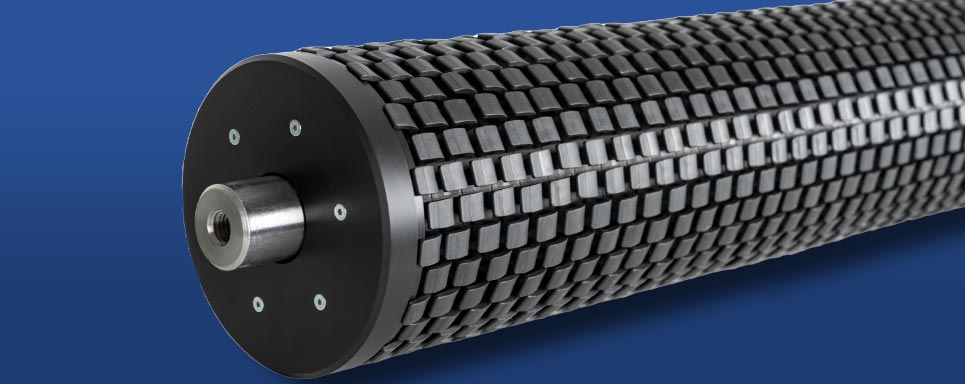

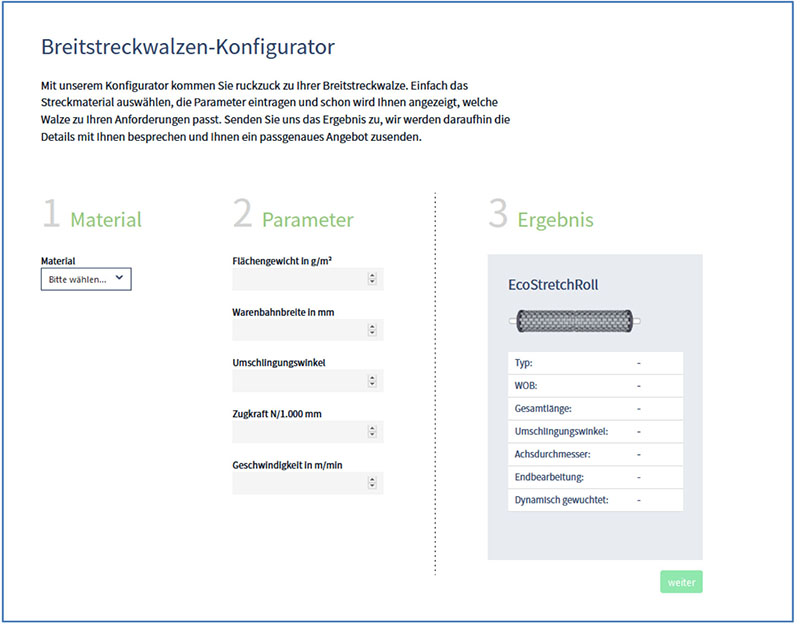

Since our customer has been using the EcoStretchRoll from DRECKSHAGE, he no longer has any problems with possible wrinkles. The EcoStretchRoll reliably prevents wrinkles at a layer thickness of 4 μm. A great advantage for the user is the possibility to use the EcoStretchRoll-ST from DRECKSHAGE also for thicker layers. This means that the same spreader roller can also be used for thicker layers, such as 150 μm, saving the need to convert to other spreading solutions.

The EcoStretchRoll from DRECKSHAGE can be used universally for a wide range of layer thicknesses, web tension, speeds and for media such as film, non-woven, textile and paper.