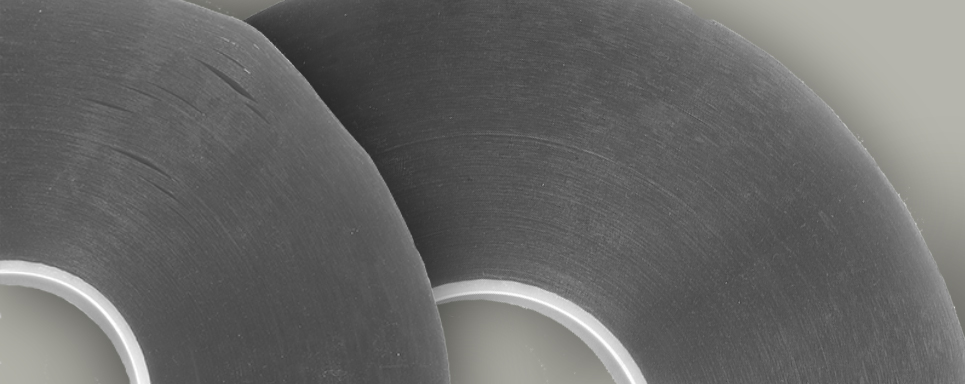

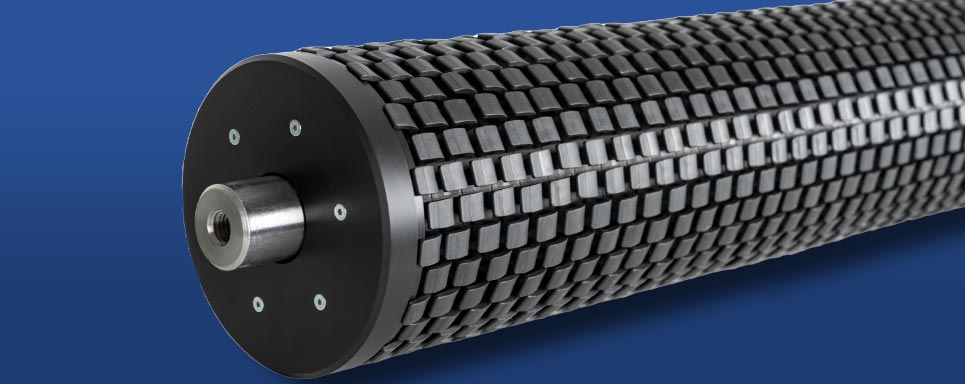

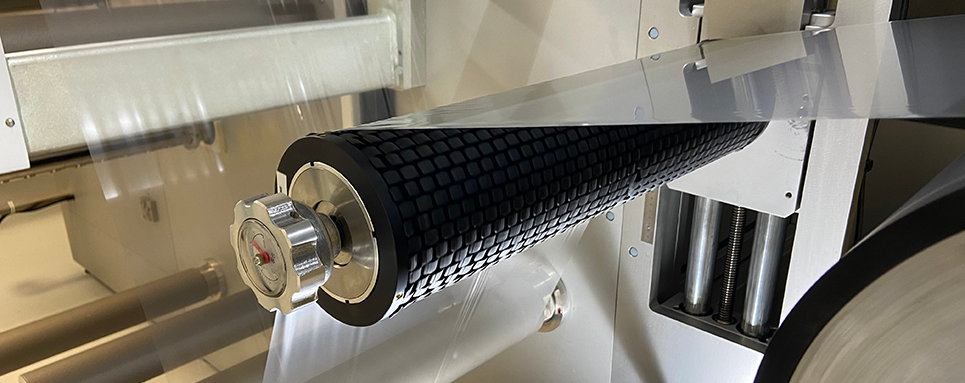

The EcoStretchRoll is used in a wide variety of applications, with a wide variety of materials. Users can produce and process films as well as nonwovens, textiles or paper with the same spreader roll. Mr Tschorn from INNO Tape GmbH reports on the successful use of the EcoStretchRoll.

EcoStretchRoll spreader roller used by INNO TAPE GmbH, Alfeld (Leine):

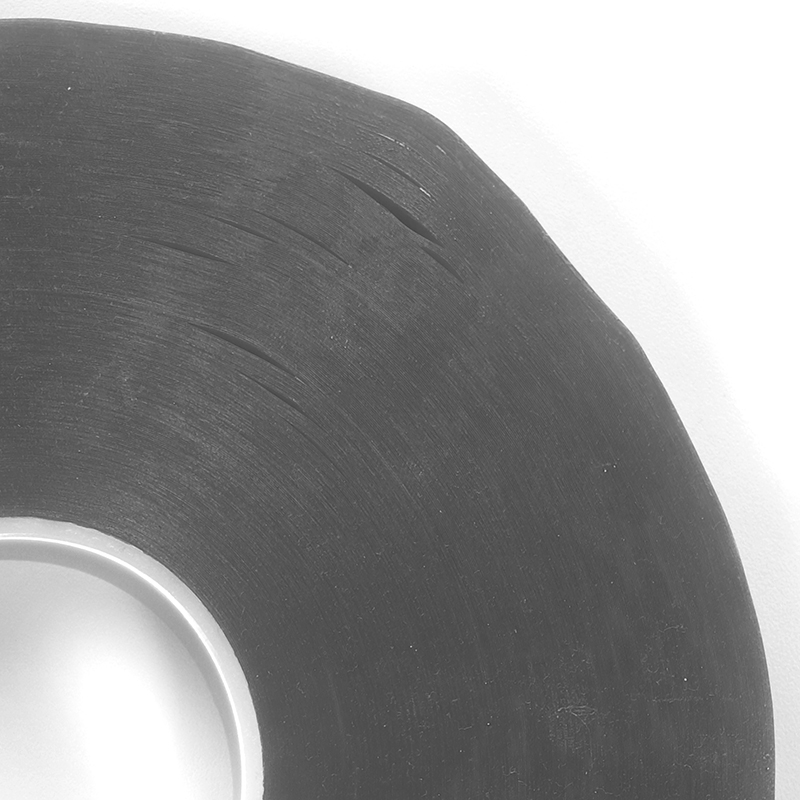

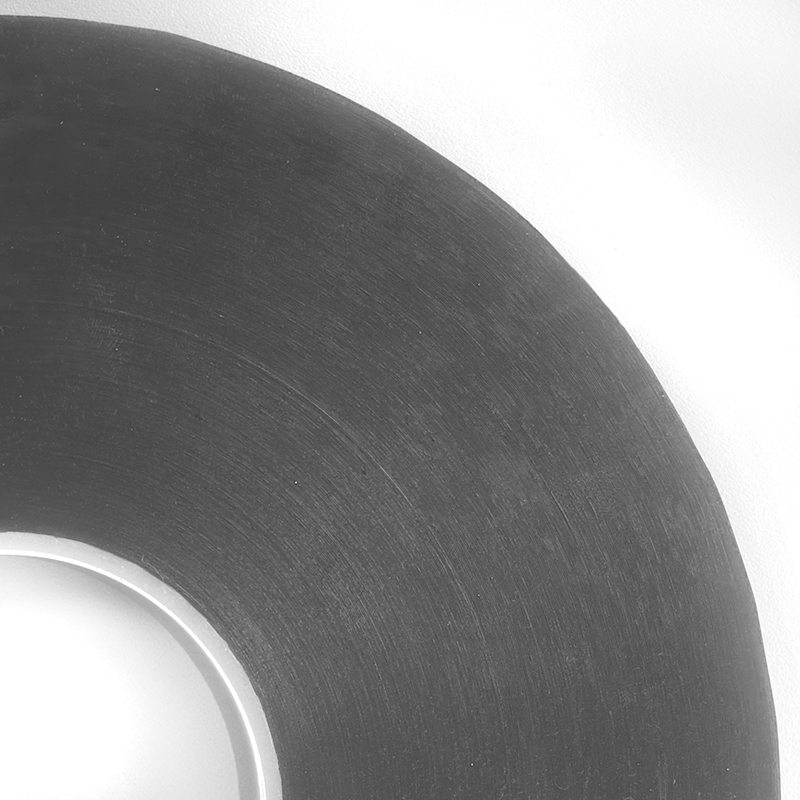

As a converter, we purchase self-adhesive materials from well-known manufacturers and process them further according to our customers' requirements. To achieve a perfect end result, all materials to be processed must be perfectly prepared. On one of our winding machines, we prepare an adhesive tape with backing for the cutting process. This is wound to a specific length according to customer requirements. "In the past, we kept running into problems with one material. The inadequate winding by our supplier was not sufficient for our processes. Unfortunately, this only became noticeable after cutting due to air inclusions and telescoped rolls. Our customer could not process rolls with this defect pattern." To achieve a better end result, the material had to be rewound beforehand. However, it was also clear that this alone would not be sufficient to get the air out of the material without creasing. DRECKSHAGE supported us here and delivered an EcoStretchRoll in the appropriate width in a very short time, which could be integrated into the system easily and without complications. Perfectly wound rolls without air pockets and wrinkles were the result. As from now on, other slides can also be used, we now have an optimal winding quality and, as a result, a perfect end result after slitting.

Um ein besseres Endergebnis zu erzielen, musste das Material vorher umgewickelt werden. Klar war jedoch auch, dass dies allein nicht ausreichen würde, um die Luft ohne Faltenbildung aus dem Material zu bekommen.

Hier unterstützte uns Firma DRECKSHAGE und lieferte in kürzester Zeit eine EcoStretchRoll in der passenden Breite, die einfach und unkompliziert in die Anlage integriert werden konnte. Einwandfrei gewickelte Rollen ohne Lufteinschüsse oder Falten waren das Ergebnis. Da von nun an auch andere Züge eingesetzt werden können, haben wir jetzt eine optimale Wickelqualität und daraus resultierend ein perfektes Endergebnis nach dem Schneiden.

René Tschorn (Production Process Development, INNO TAPE GmbH)

Extrusion World test campaign:

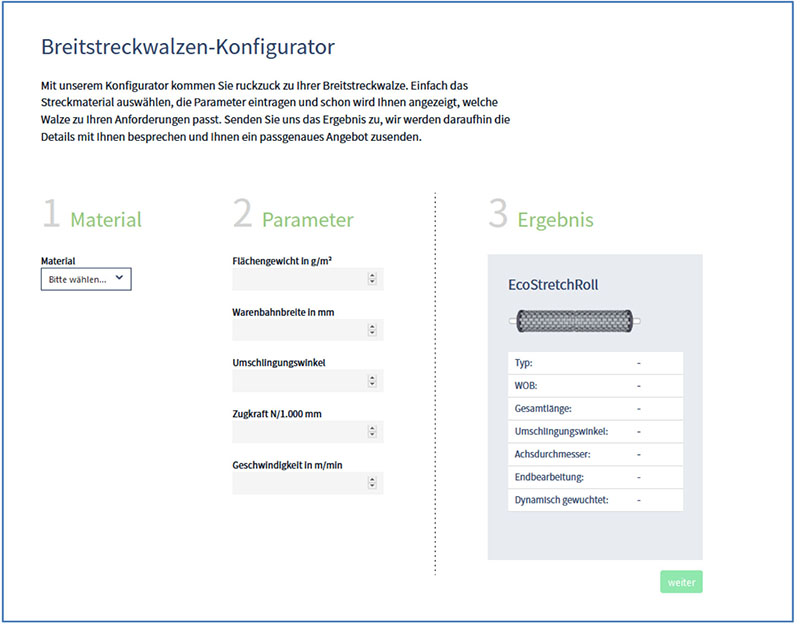

The EcoStretchRoll can be returned if it does not function properly. Your responsible contact person will be happy to advise you on site to discuss the perfect installation situation