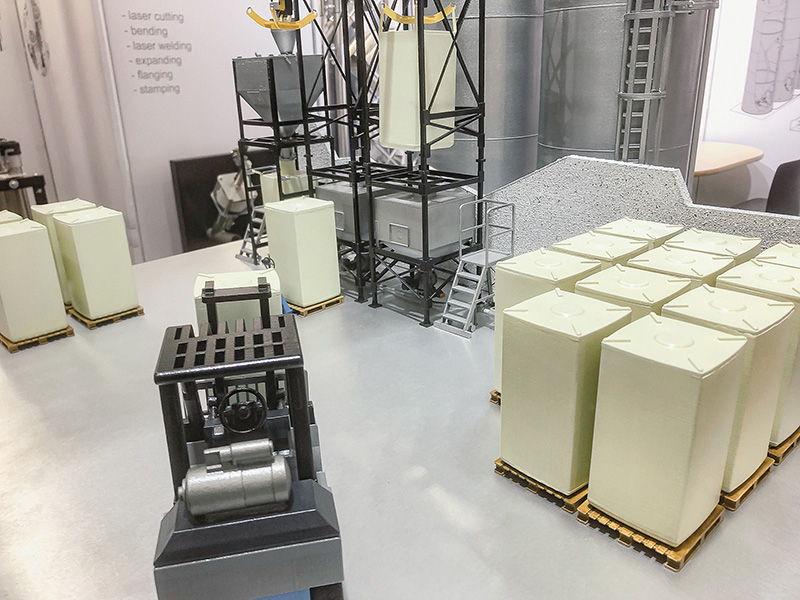

Especially in plastic injection moulding plants, plastic containers (material bins, waste bins) are ubiquitous and almost unimaginable without them - although the disadvantages, such as electrostatic charging, the risk of tipping or poor residual emptying, are well known. Siloanlagen Achberg has developed an easily retrofitted suction nozzle to reduce the risk of tipping and to enable optimum residual emptying. Retrofitting is very simple: a template is used to cut an opening in the rear wall of the plastic container so that the suction nozzle can be inserted and screwed to the screw-on counter plate.

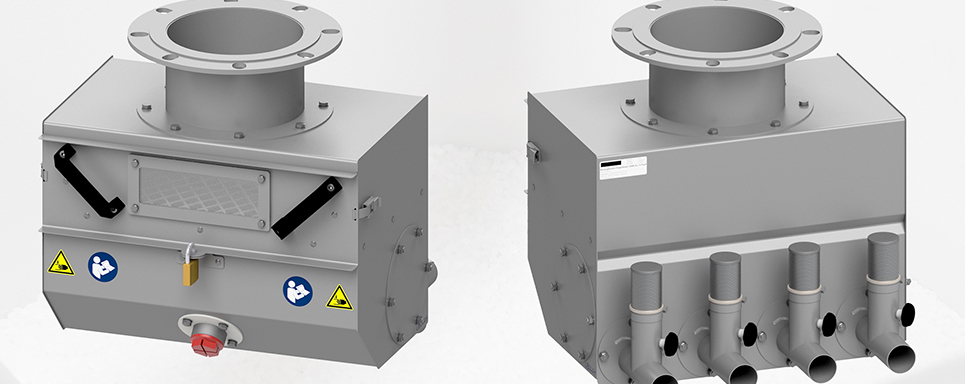

The retrofit system, made of stainless steel, consists of the suction connection piece, the screw-on counter plate and the necessary screws. The counter plate is equipped with threaded rivets so that there are no nuts inside that could come loose and fall into the granulate. The suction nozzle is available for all common pipe system diameters and has a flap to prevent contamination when there is no suction lance in the guide pipe. Of course, Siloanlagen Achberg also supplies the matching suction lances.