BigBag-Handling in the plastics industry

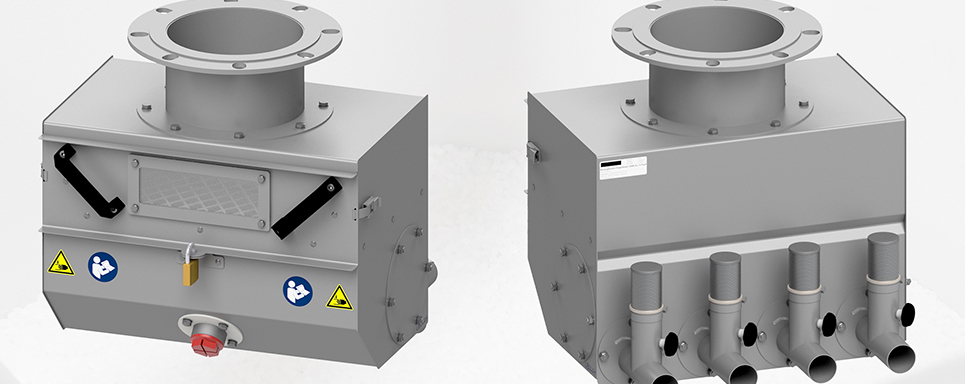

The demand for BigBag emptying systems from Achberg has increased more than significantly since the K trade fair last October, according to the sales department of the southern German manufacturer. The great advantage of the modular and stable steel constructions is the well-thought-out construction and the cost-effective shipping of the components.

There are two different ways of handling the BigBags: On the one hand, the BigBags can be transported to the emptying station with a lifting traverse and forklift and hooked into the emptying station. On the other hand, it is possible to transport the BigBag into the emptying station with the help of a mobile electric chain hoist with a lifting cross. An integrated container, which is available in a wide range of sizes and configurations, holds the bulk material as an intermediate buffer. From there, the bulk material can be emptied by pneumatic vacuum or pressure conveying.

BigBags are usually used in the plastics industry for the storage of raw materials and the in-house transport of a wide variety of bulk materials. These can be granulates, regranulates, regrinds, flakes or powders. Depending on the bulk material properties, special discharge options are necessary to ensure process-safe emptying and discharge.

Since many years, Siloanlagen Achberg is producing the BigBag emptying systems for exactly these applications in the plastics industry. In the beginning, the metalworking company constructed and manufactured the steel frames on a project-specific basis. Over time, more and more standardisation took place and a modular system was built up. With this standardisation, Achberg now covers over 90 % of the project-related applications.