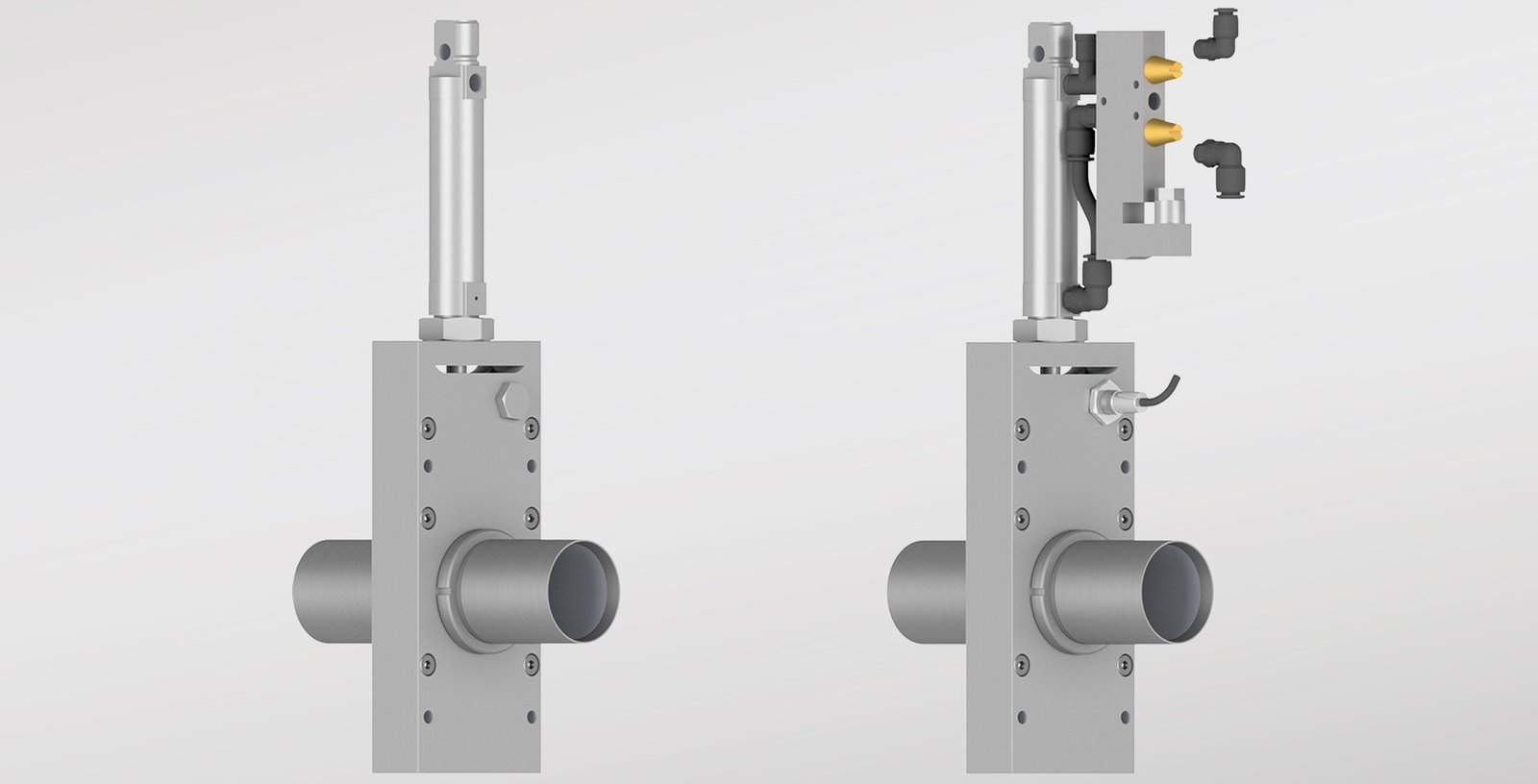

The southern German manufacturer has relaunched its well-known slide valve. The optimized product is named AS.11 and offers improved position sensing of the slide valve compared to the previous model.

Previously, the position of the slide valve (AS.10) was monitored by two end position sensors on the pneumatic cylinder. The smaller switching range and the complex mounting of the end position sensors were a disadvantage and one of the reasons for the product revision. The new version of the slide valve now only has one sensor for position monitoring. Its position is fixed by a threaded hole in the slide valve body. Mounting is very simple and can be carried out without any specific skills.

The optional sensor for position monitoring checks the position of the slide plate more reliably and over a larger area. This enables safe and efficient monitoring of the slide valve and ensures greater process reliability.

"With the new sensor for position monitoring, we are offering our customers an optional and even retrofittable monitoring function that increases the reliability and availability of systems," says Gerd Maass, Managing Director of Siloanlagen Achberg. “We are convinced that this optimized slide valve is a good addition to our product portfolio and, above all, that it will help our customers.”

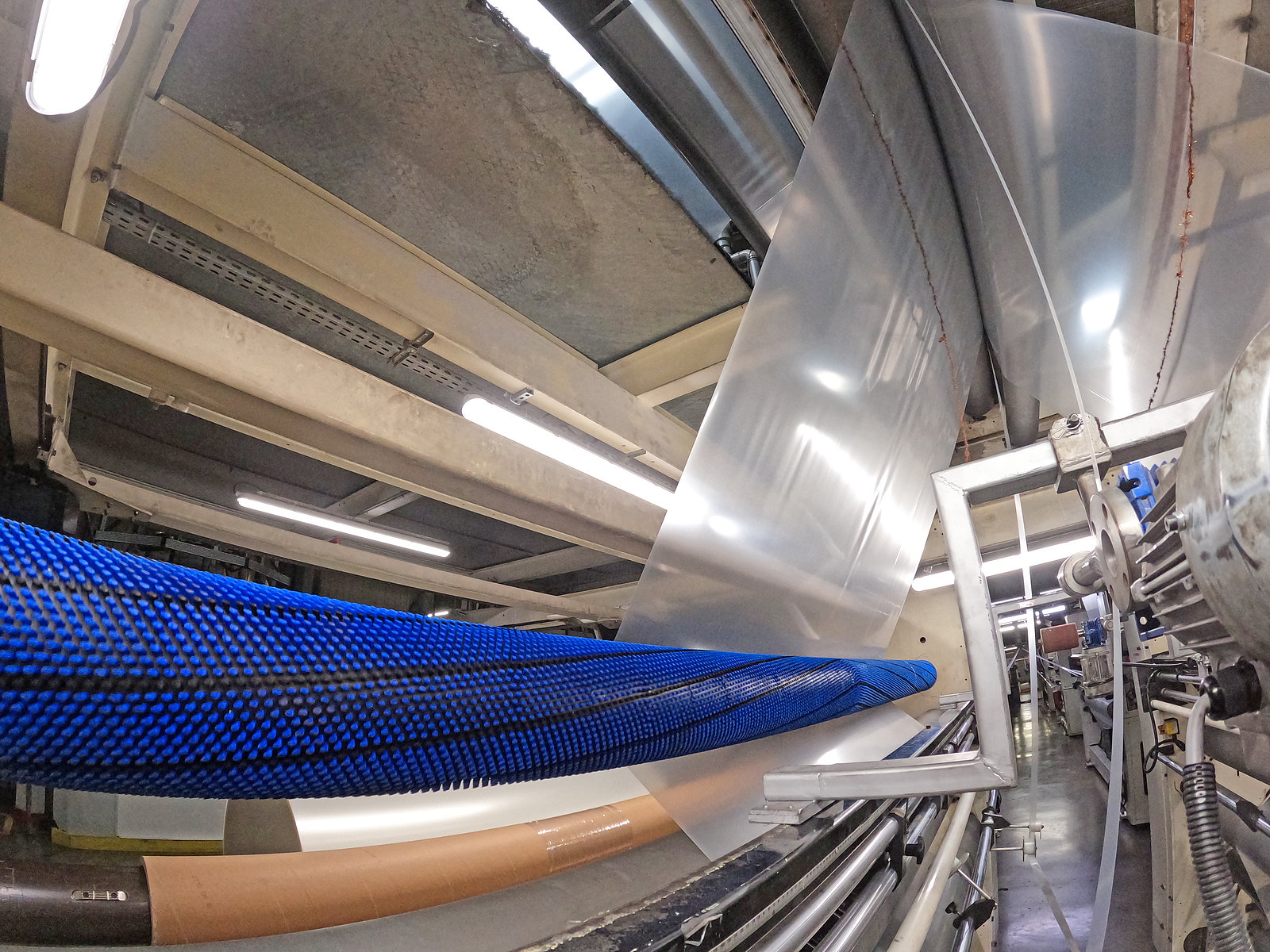

The new AS.11 slide valves with optional position monitoring can reliably close and open pipelines with a full cross-section even during conveying. They are suitable for use in material and vacuum lines and are available in various sizes and types.

About the company

Siloanlagen Achberg GmbH & Co. KG is a family-owned, medium-sized company. It currently has 70 employees. The company’s history started in 1999 when Siloanlagen Achberg GmbH was founded by Mr Gerd Maass. The company’s pillars of business are in metal processing (stainless steel, steel and aluminium), electrical engineering and silo plant construction.