Countless producers of films and nonwovens could be more productive today if they fully exploited the enormous potential of digitalization. In doing so, the company is focusing on the empowerment and independence of customers - and is deliberately turning away from the usual vendor-centric approaches. Instead, Reifenhäuser offers easy-to-implement, open digital solutions designed to help producers of films or nonwovens worldwide to increase their production efficiency (OEE) independently and sustainably. All customers, regardless of company size, thus benefit from a new dimension of process transparency that for the first time includes all line manufacturers and line types of a production.

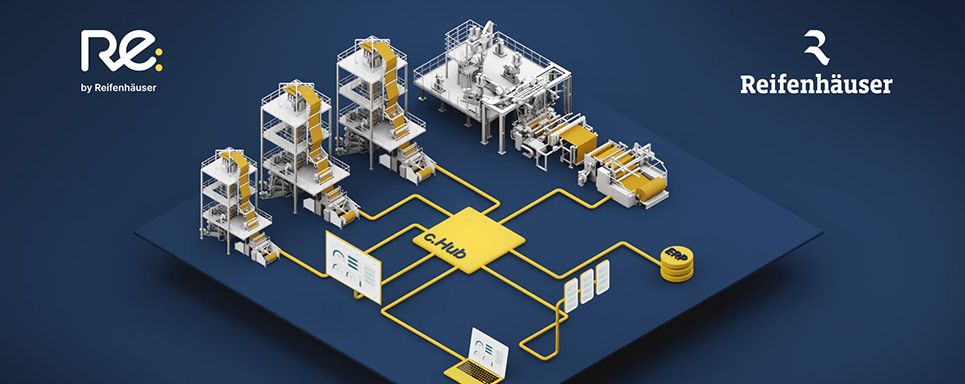

The core of the digital solution is the so-called c.Hub, a middleware that ensures the secure exchange of data between different IT systems, applications, extrusion machines and line controls. This includes Reifenhäuser systems as well as third-party systems. The c.Hub becomes the single point of truth for all production-relevant data by merging and harmonizing production data streams. The central advantage is that all users can access all data from anywhere at any time and document them securely. The data is collected and stored on premises without interfering with the production process. The producer retains full control over the data at all times.

"So far, digitization in our industry has mostly failed due to heterogeneous factories with machines and peripherals from different vendors and of different ages and types, as well as applications that are not connected with each other," says Daniel Kajan, Director Product & Operations at RE:, a Reifenhäuser Group subsidiary specializing in digital products for extrusion line operators. "Without looking at the big picture, however, production is inefficient and error-prone. Unnecessary complaints, material loss and downtime are the result. Only a cross-vendor solution maps the production reality of our customers and thus offers real benefits," Kajan continues.

To enable customers to easily connect all their equipment in production, Reifenhäuser offers out-of-the-box connectors for the most important industrial protocols. They enable fast and complete acquisition of all production data. The associated ExtrusionOS software provides user-friendly applications and dashboards that help monitor, manage, store and analyze this data. Line operators can, for example, monitor the condition of their connected equipment and adjust it optimally based on the knowledge gained. They also have the option of monitoring defined thresholds and KPIs and, if desired, receiving notifications when thresholds are exceeded. This enables users to act faster and more efficiently, thereby significantly reducing errors and customer complaints. Legal requirements such as compliance with EFSA-relevant threshold values when processing recyclate for direct contact with food can be monitored and documented securely.

"Our open digital ecosystem helps line operators capture all production data from the first meter to the last meter of the roll, easily gain insights from it, and benefit from their data in the long run," Kajan explains.

The digital package can either be purchased together with Reifenhäuser machines or retrofitted on existing lines and servers.

About the Reifenhäuser Group

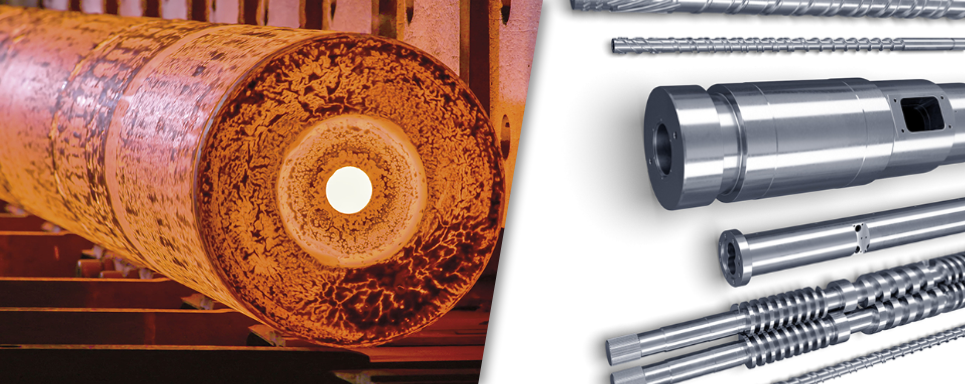

The Reifenhäuser Group is the leading provider of innovative technologies and components for plastics extrusion. Founded in 1911, the company supplies high-technology solutions all over the world. With its technologies and the know-how of its 1,750 employees, Reifenhäuser has the world's largest network of expertise in plastics extrusion technologies. The CEO of the Group is Bernd Reifenhäuser.