The Reifenhäuser Group will be represented with four booths at the world's leading trade fair for plastics processing, K 2022, from October 19 to 26. Under this year's Reifenhäuser motto "The Time is Now", the extrusion specialists will show producers of films and nonwovens valuable solutions for the three major topics of the industry: sustainability, digitalization and productivity.

Bernd Reifenhäuser, CEO of the Reifenhäuser Group, explains: "The world and our industry are facing major challenges. There is uncertainty, disorientation and unanswered questions on many topics. And yet they will not tolerate any delay. Now is the time to act and turn challenges into opportunities. We have know-how for this as well as great, immediately applicable solutions in our luggage, with which we enable our customers and partners to do so."

Reifenhäuser lines and components at a total of four exhibition booths

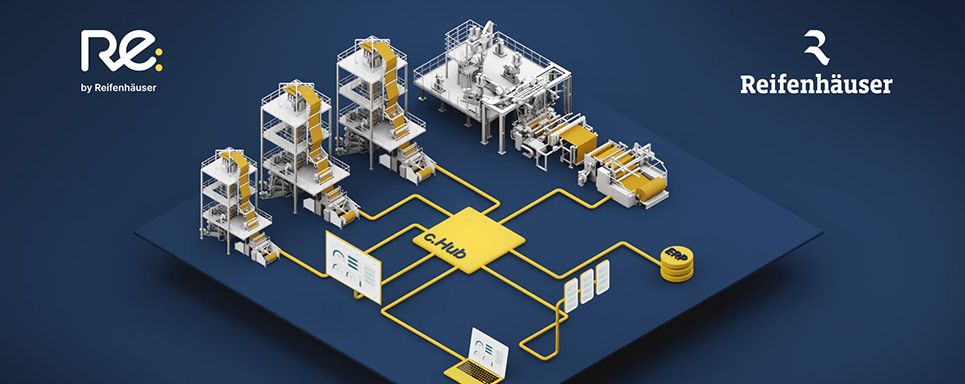

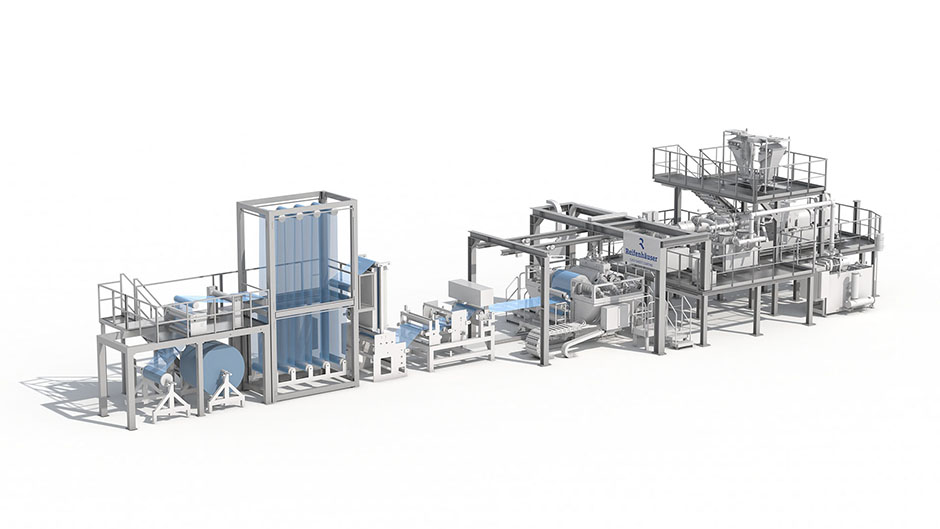

The Reifenhäuser Group will be represented at three of its own booths and one joint booth in Duesseldorf. The main booth with approximately 1,200 square meters is located in Hall 17 (C 22) and impressively showcases the Reifenhäuser Blown Film, Cast Sheet Coating and Reicofil business units. With the help of machine exhibits, visual presentations and concrete solutions for end products, visitors will learn, among other things, how they can manufacture fully recyclable products economically, process recyclates safely, increase their output and network the entire production without becoming dependent on systems, specialists or manufacturers. To ensure smooth production even after purchase, Reifenhäuser Service shows how customers can get the best out of their Reifenhäuser products and increase their productivity with rework solutions, modifications, training programs and digital services.

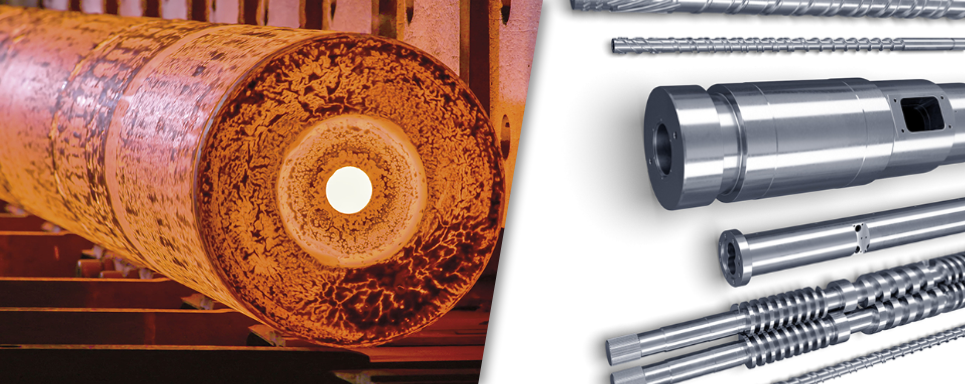

The component specialists of the Reifenhäuser Extrusion Systems business unit will additionally present their portfolio at two other exhibition booths. In Hall 11 (C16), everything revolves around screws, barrels and extruders - and why, especially for processing recycled material, high-performance wear protection is essential for reliability and high economic efficiency. The wellknown Reifenhäuser Reiloy wear protection alloys for screws and barrels have repeatedly achieved top values in independent tests, proving that investing in high-quality wear protection pays off. In Hall 1 (D91), Reifenhäuser Extrusion Systems will showcase its innovations for flat dies and coextrusion blocks and their perfectly coordinated interaction for maximum productivity.

R-Cycle: Sustainability meets digitalization in the Circular Economy Forum

In addition to its own booths, Reifenhäuser will also be present as a partner of the R-Cycle initiative as part of a joint pavilion on the open-air site in the so-called Circular Economy Forum (CE 07). R-Cycle is a cooperation project of various technology companies and organizations along the entire life cycle of plastic packaging. The interdisciplinary team has developed an open traceability standard for sustainable plastic packaging that makes recyclingrelevant information transparent by providing a Digital Product Passport. This enables waste sorting facilities to more precisely identify recyclable packaging and form recycling-friendly and single-variety fractions. This is the basis for obtaining high-quality recyclates to build a functioning circular economy.

From the exhibition booth to the Reifenhäuser Technology Center

A special highlight for visitors to the Reifenhäuser trade fair booths is the opportunity to additionally participate in the in-house exhibition on October 20, 21 and 24 at the Reifenhäuser Technology Center. For this purpose, Reifenhäuser organizes a free bus shuttle between the Duesseldorf trade fair and the Reifenhäuser headquarters in Troisdorf, which is only about 70 kilometers away. Here, the guests can experience various blown film and flat film lines in operation during two moderated live demonstrations per day. Interested parties can contact their Reifenhäuser representative to inquire about participation.

» Details on the product highlights are available as separate press releases in the Reifenhäuser press kit:

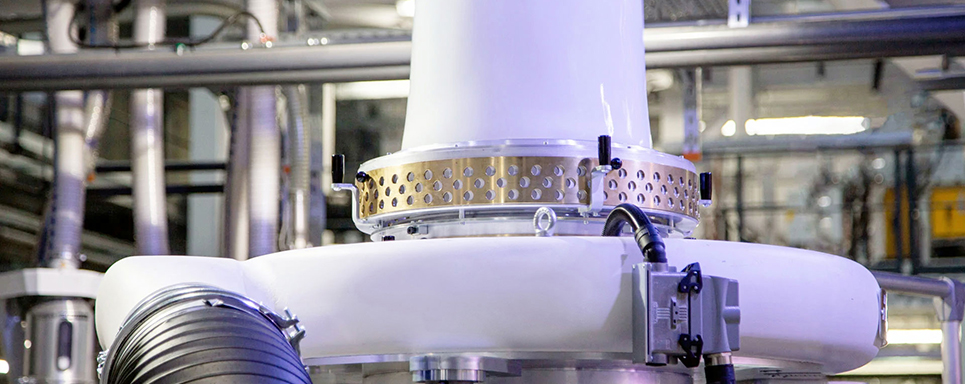

1. Reifenhäuser Blown Film provides technical solution to one of the biggest challenges in the processing of recyclate

2. Record output rates beyond 600 kg/h for form-fill-seal sack applications with Reifenhäuser Ultra Cool 2.0 FFS

3. Fully recyclable pouch – now also with barrier effect for food packaging

4. EFSA/FDA-compliant production process enables manufacture of foodsafe film from PET recyclate

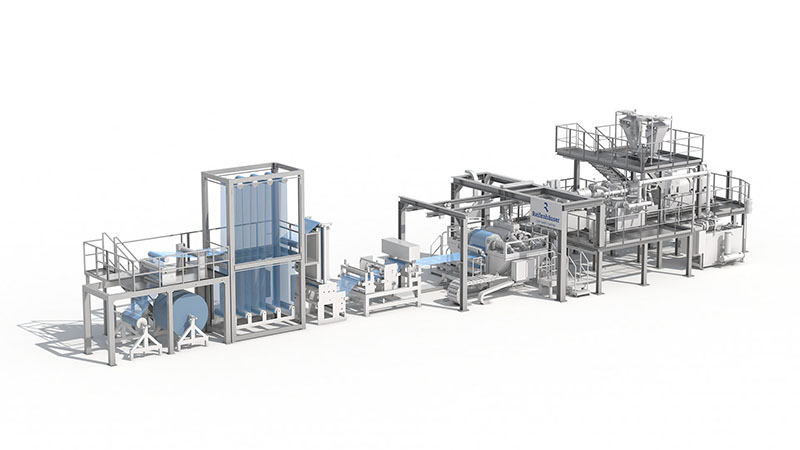

5. New "Ultrathin Coating" process enables production of particularly lightweight and cost-effective film/nonwoven composites

6. Film-nonwoven mono composites as a lightweight and recyclable alternative to paper-plastic packaging

7. Highly wear-resistant screws and barrels enable safe recyclate processing

8. Cross-vendor approach: Reifenhäuser launches digital offensive that focuses on enablement of film and nonwovens producers

9. Reifenhäuser Group Fact Sheet: Over 100 years of experience, competence and pioneering spirit

10. R-Cycle: Digital Product Passport enables circular economy for plastic packaging

The Reifenhäuser K 22 booths at a glance:

Reifenhäuser main booth (blown film, flat film, nonwovens lines, service, digitalization, components): Hall 17 / C 22

Reifenhäuser screws, barrels and extruders: Hall 11 / C16

Reifenhäuser flat dies: Hall 1 / D 91

R-Cycle: Circular Economy Forum (CE 07)

Details on the product highlights are available here as separate press releases:

Reifenhäuser Presskit 2022