The plastics industry is in a constant process of innovation and ideas that were a trend yesterday are core requirements today. Latest example and therefore key topic at the upcoming trade fair K: Sustainability in products and production processes. At Erhardt+Leimer optimizing production processes including minimizing environmental hazards like unnecessary waste or inefficient use of raw materials, is a key objective of many of our systems and solutions. To continue helping you to keep up with the ever-increasing level of requirements, we are proud to present two new products.

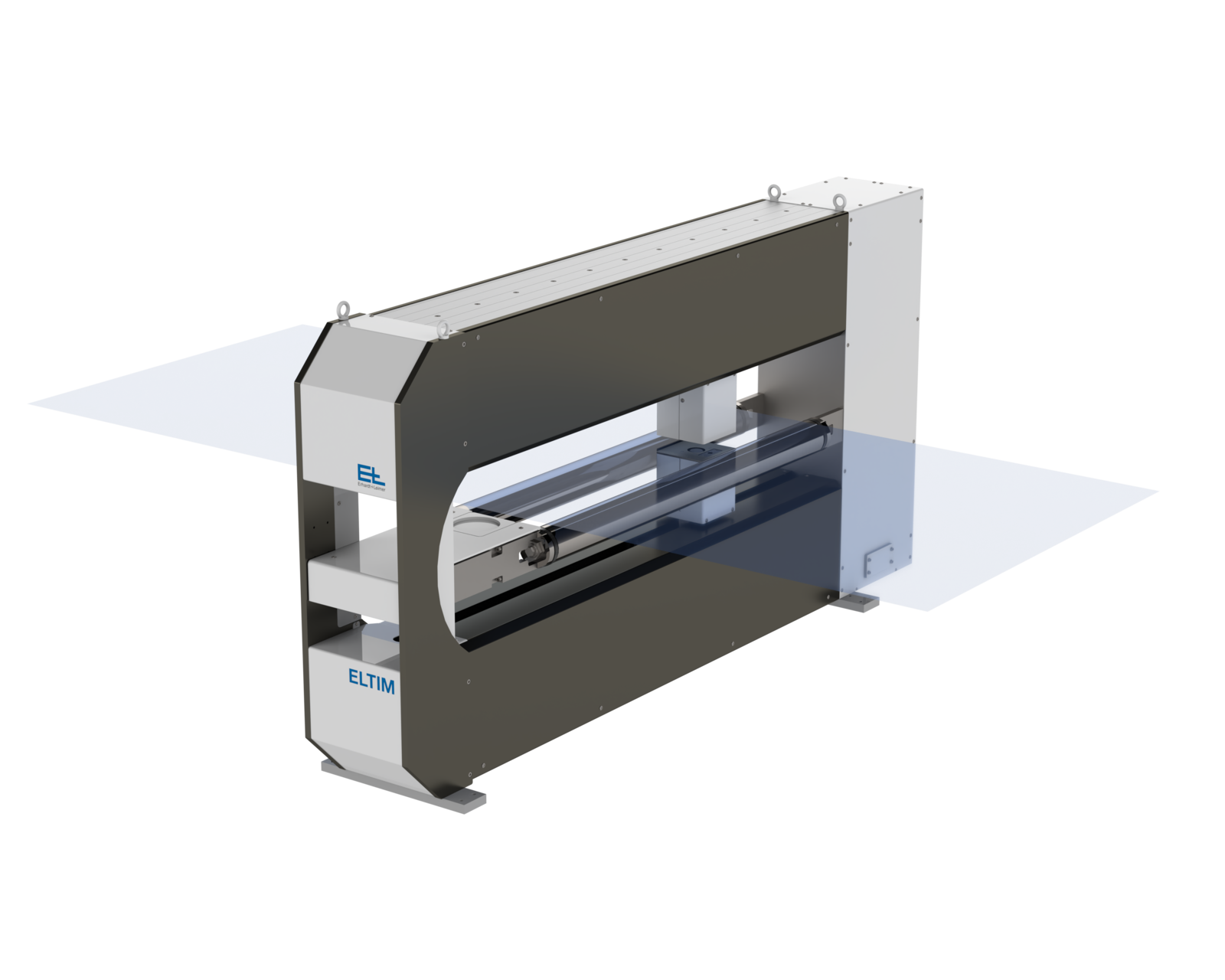

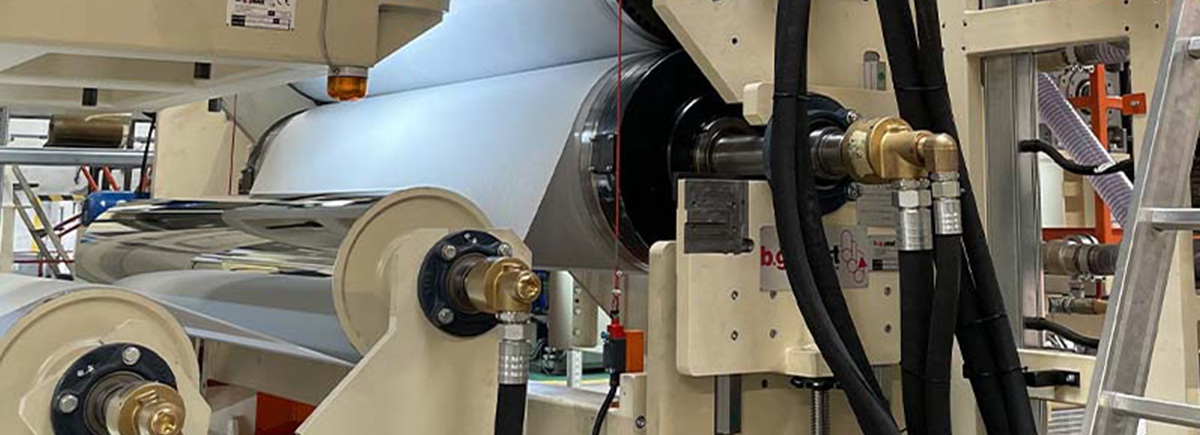

ELTIM O-/C-frame - Inline basis weight and thickness measurement system

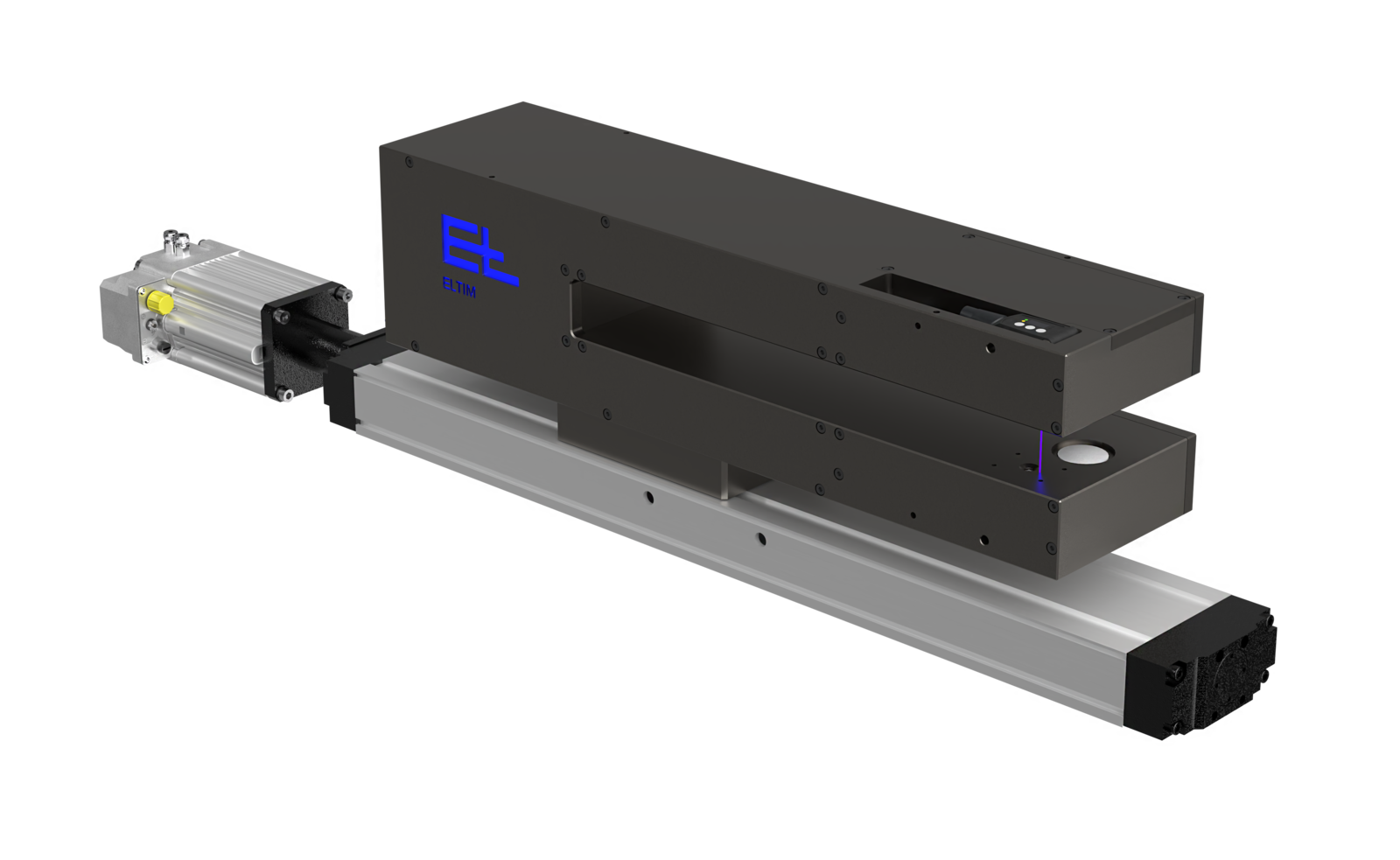

Our well known ELTIM O-frame system uses ultrasonic technology to measure basis weight safely and non-contact – without any harmful radiation. The system delivers stable results independent of color, fillers, or surface variations. Additional sensors record ambient conditions such as temperature, humidity, or air pressure to ensure reliable and reproducible measurements.

To broaden application possibilities, we now have added an ELTIM C-frame version, fit for installation with limited space.

- Space-saving and easy to integrate:

Ideal for systems with limited installation space or access from one side – also for retrofitting. - Flexible in use:

Optionally available on linear guide with motor drive – for flat measurements over the entire traversing path. - Improved accessibility:

Open design on one side – for easy operation, cleaning and visual inspection. - Versatile use - inline or offline:

Also available as a stand-alone version for laboratory environments – ideal for development, quality assurance or sample testing. - Robust and maintenance-free:

Durable, reliable and without mechanical maintenance – for maximum availability. - ATEX – EU explosion protection directive:

ELTIM systems will soon be available in special versions for use in EX areas. EX zones and design on request.

ELTIM basis weight measurement systems

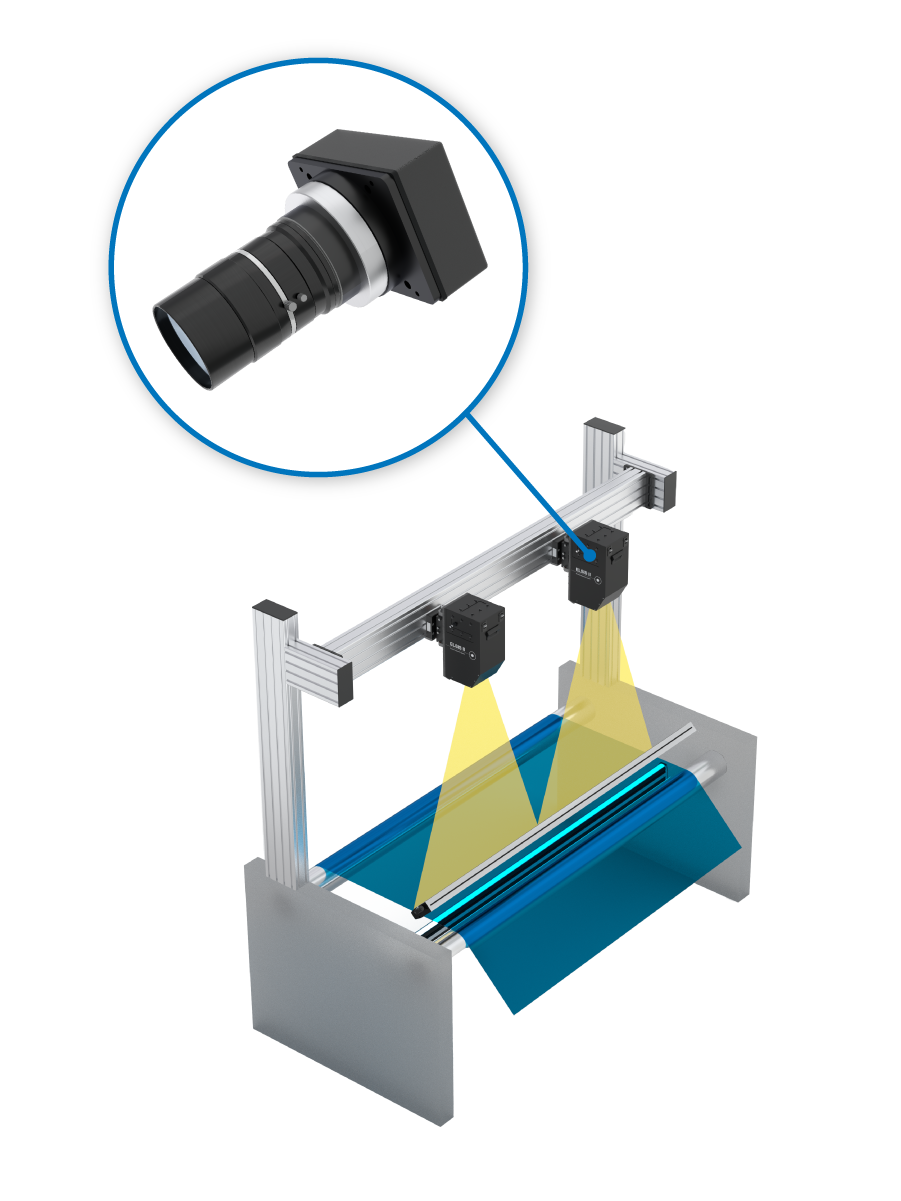

ELSIS II - Surface inspection system

Regardless of whether paper or film/foil, production or processing, for the food, pharmaceutical, battery or hygiene industry, quality requirements have increased everywhere. This has made inspection systems a must in every processing machine. ELSIS II inspection systems truly master this task. Highly sensitive line scan cameras detect any deviation and alert the operator without delay if there is a defect. The automated control of signaling devices such as lamps, horns, marking units and even complete machine control systems can be implemented using the flexible ELSIS I/O control system.

- High-speed line scan cameras for finding smallest defects

- Customized lighting concept tailored to your application

- Brand new user interface with modern look and user-friendly operation

- Create your own operation panel based on the truly important information

- Comprehensive user management for security-related applications

- Data backup through UPS and RAID protection

- Detailed logging of inspection results

- Remote maintenance support and on-site training provide your team with optimal qualifications

Adapt ELSIS II exactly to your project and detect defects reliably.

ELSIS surface inspection, film/paper

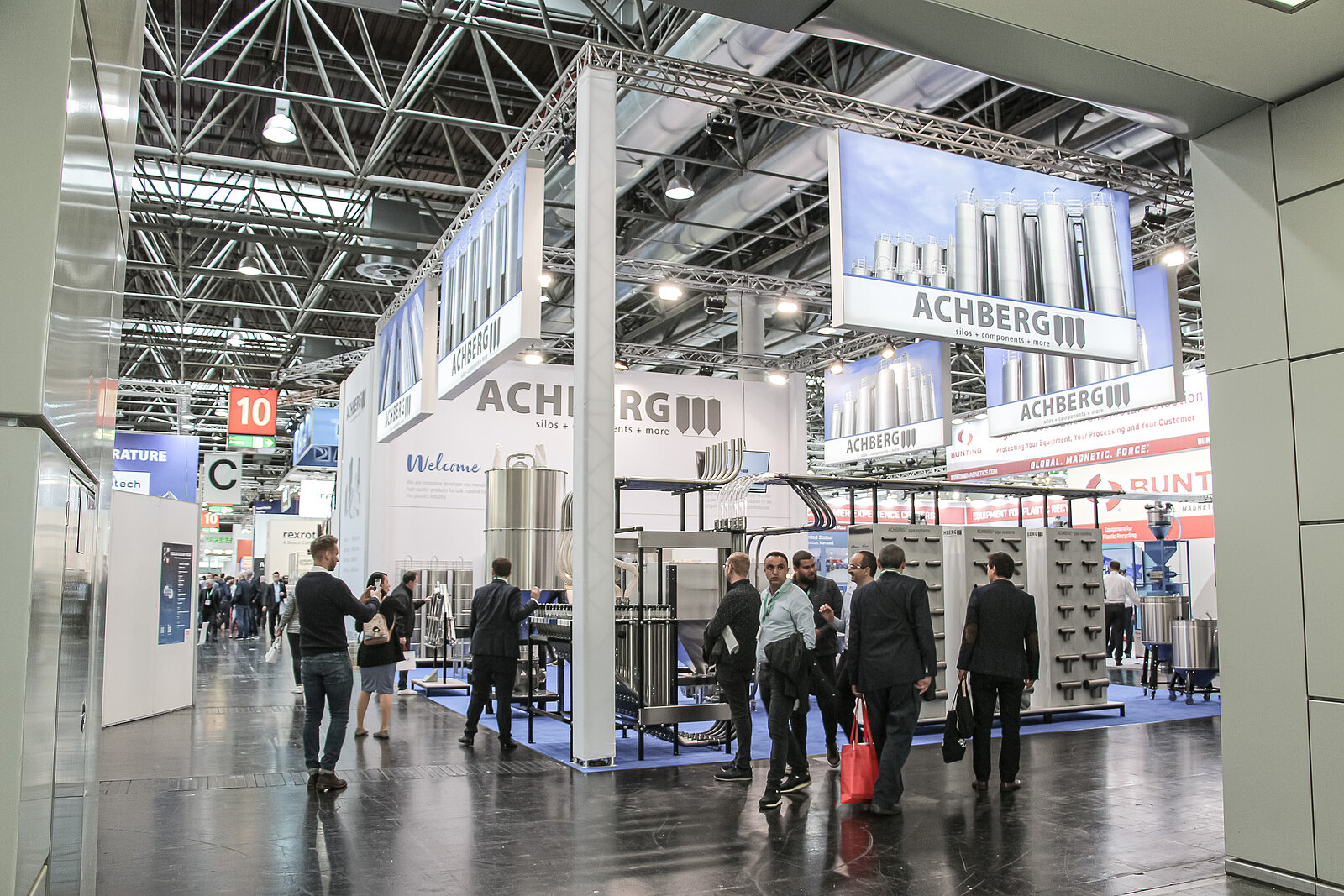

Meet us at K 2025 and be among the first to explore our new products as well as all other Erhardt+Leimer solutions for web guiding, web tension control and drive technology.

October 08 – 15, 2025

Hall 4 Booth 4C20

Düsseldorf, Germany

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/8/csm_Cropped_DSC_8815_52594d6c04.jpg)