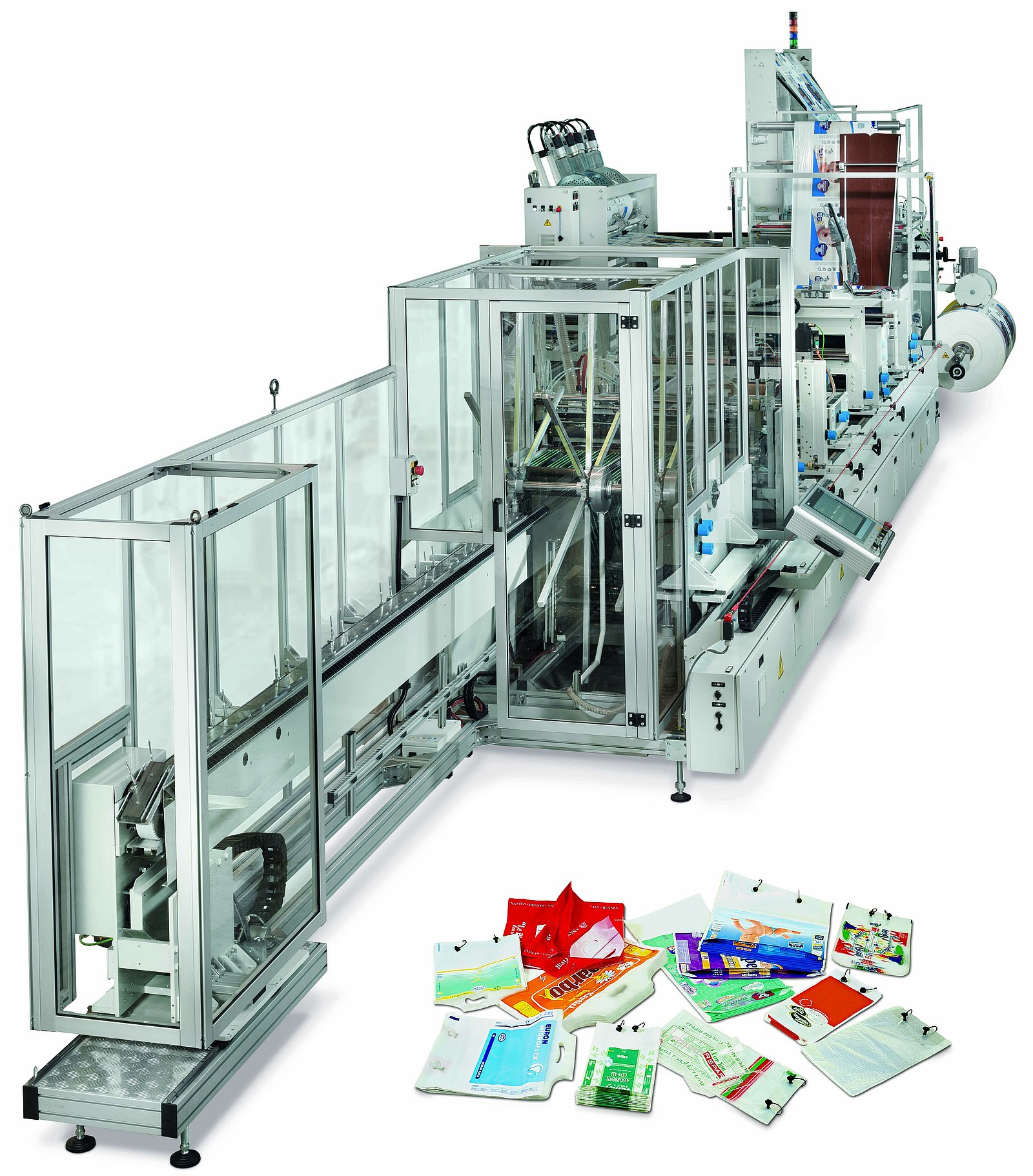

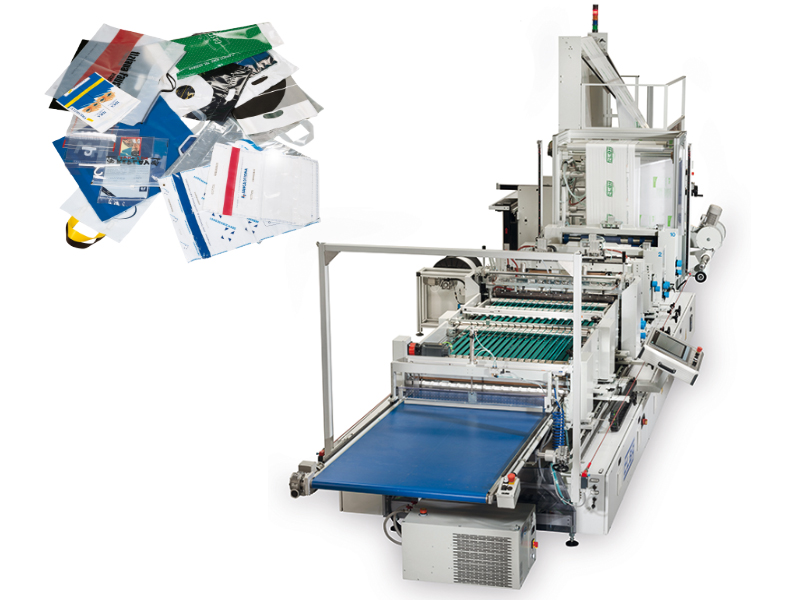

The SA-W machine has been designed to produce a wide range of wicketed bags like bottom gusset bags, bread bags, poultry shrink bags, hygiene bags and diaper bags (with cross or paramount handles). The machine design offers its customers a high level of flexibility in terms of types and sizes of the bags, in order to maximize the investment with a short payback period.

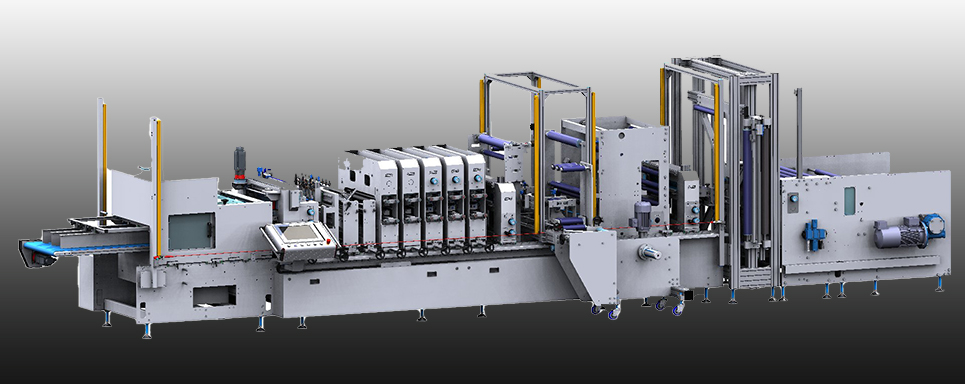

The SA-W is fully equipped with Siemens components and it is entirely controlled by a state-of-the-art HMI based on Profinet®, one of the most advanced communication protocols: it controls each of the installed stations/tools independently and in real time and, consequently, the whole production process. Each station is independent, servo driven and plug & play.

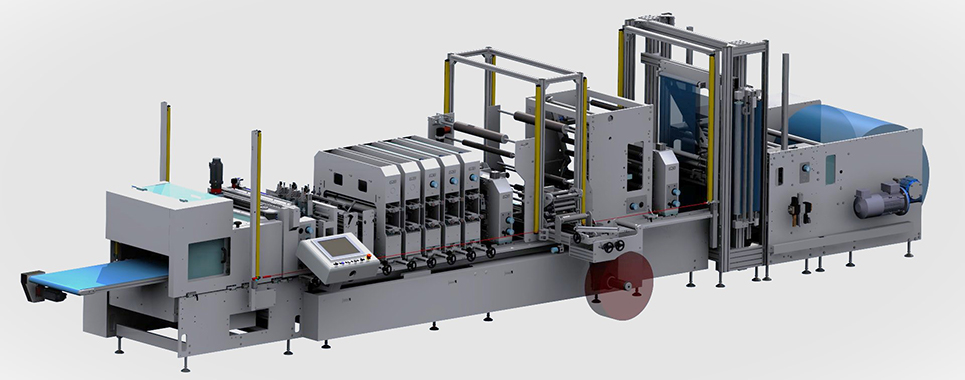

As setup and changeover times are critical, the SA-W machine has been designed to guarantee a short and easy job changing. The machine easy accessibility for setup and maintenance is ensured by the new frame design, too.