From October 8 to 16, 2025, the motan Group will be exhibiting at the K Show in Düsseldorf in Hall 10, Booth D02/04, with a strong product portfolio for a wide range of applications in plastics processing. Highlights include new offerings from the cost-effective swift product range and intelligent solutions for the automation of extrusion processes.

swift – A powerful response to current market conditions

With its new swift product brand, motan is introducing cost-effective solutions for auxiliary equipment in materials management. The standardized units offer the usual motan quality and are equipped with state-of-the-art control technology. They have been specially developed for companies that do not want to compromise on efficiency, reliability, and ease of use, especially when faced with increasing cost pressure.

The swift series covers the entire product range for materials handling, from dosing and mixing to drying and conveying. Highlights at the booth include:

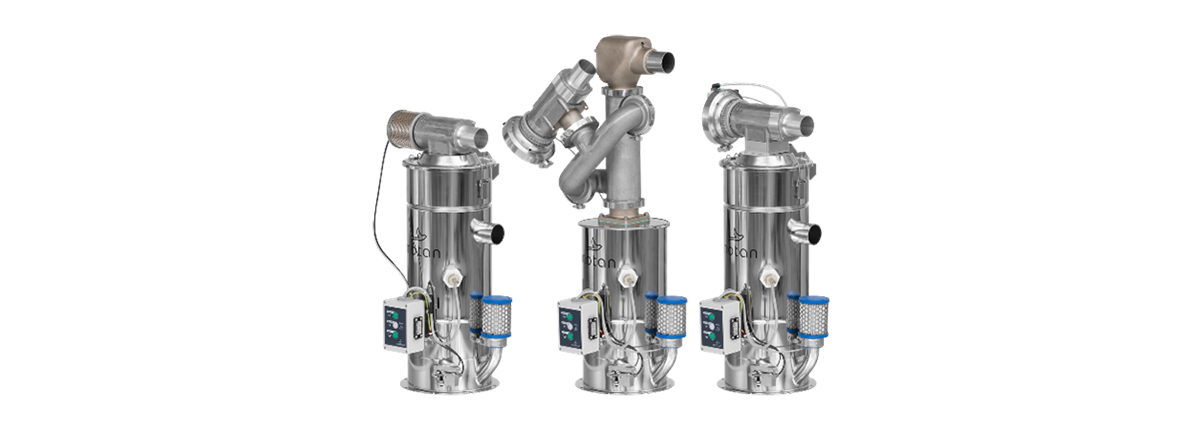

- sDRY 40/80: A flexible and compact small, dehumidified air dryer range with multiple bin combinations possible, focused on energy efficiency.

- sCOMPACT: A flexible dehumidified air dryer with integrated conveying and optional control of an additive dosing unit via its color touch display.

- sCONVEY HES: A compact single-phase material loader for granulates with intelligent control for demand-based material supply.

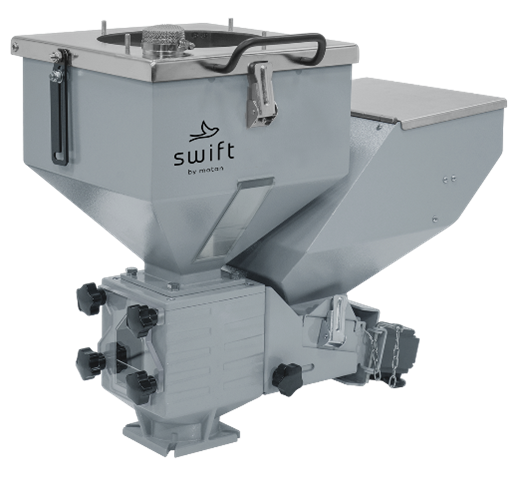

- sCOLOR V Additive dosing and mixing unit: Ideal for masterbatch and regrind dosing applications, offering fast delivery and cost-efficient performance.

“Our swift products prove that affordable solutions do not have to compromise on quality, control, or sustainability. They are our direct response to a market environment that demands both efficiency and affordability,” says Carl Litherland, CMO of the motan Group.

For even more convenience, numerous swift products are available in the online shop. They can be ordered 24/7 at https://shop.motan.com/, with transparent prices and short delivery times.

Precise applications for the most demanding requirements – medical technology & extrusion

motan provides sophisticated system solutions for areas with particularly high requirements for traceability, precision, and hygiene, such as medical and pharmaceutical technology and extrusion. The GRAVICOLOR 110 med and METRO G med are specially designed for pharmaceutical and medical plastics processing. They comply with FDA standards and guarantee maximum process reliability for sensitive materials.

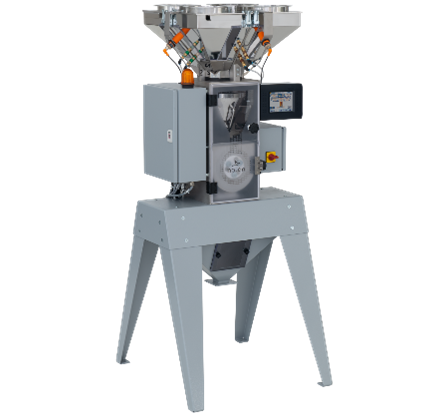

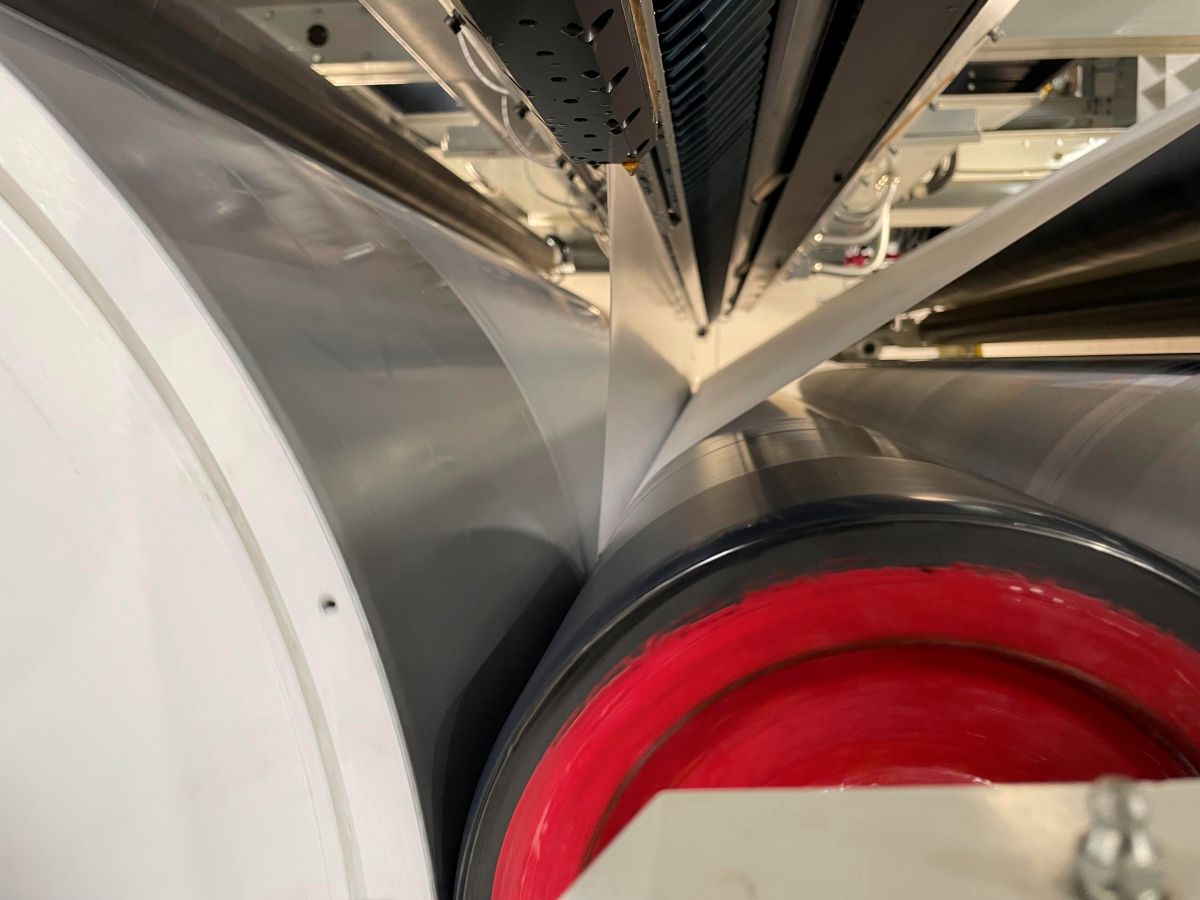

Consistently high quality and precise process control are crucial for extrusion. motan offers with the new SPECTROFLOW intelligent system solutions that are tailored specifically to the requirements of continuous extrusion processes. These volumetric and gravimetric dosing and mixing systems are intended for both flood-fed and starve-fed extruders. The new GRAVIFLOW loss-in-weight hoppers are designed for gravimetric throughput measurement of free-flowing bulk solids such as granulates and regrinds. They are available in various sizes and cover throughputs from 1 to 1,500 kg/h. The GRAVIFLOW units are characterized by their high flexibility when it comes to integration into control systems.

Visit motan at K 2025

Experience at first-hand how motan combines efficiency, digitalization, sustainability, and affordability in materials management. Visit us at the K Show 2025 from October 8 to 16 in Düsseldorf, Hall 10, Booth D02/04, and discover our latest products and system solutions for economical and future-oriented plastics processing.

The motan-group

The motan group based in Constance was founded in 1947. As leading provider for sustainable raw material handling, they operate in the areas injection moulding, blow moulding, extrusion and compounding. Innovative, modular system solutions for storage, drying, conveying, dosing, and mixing of raw materials for the plastics manufacturing and processing industries are part of the application orientated product range. Production takes place at different production sites in Germany, India, and China. motan distribute their products and system solutions via their regional centres. With about 600 employees currently, a yearly turnover of roughly 151 million euros is achieved. Because of their network and long-standing experience, motan can offer their customers what they really need: Individually tailored solutions with real added value.