Hardly any other topic has dominated science, politics and society in recent years as much as global warming. To counter it, experts worldwide see the minimisation of CO2-intensive plastics as a clear goal. Numerous well-known international brands and retailers have committed themselves to making all packaging recyclable by 2025. Thus, the development of environmentally friendly packaging materials is a current and relevant mission, which Hosokawa Alpine from Augsburg in southern Germany has accepted. The machine manufacturer has already accumulated 25 years of experience in film stretching technology. With the further development of the proven Machine Direction Orientation (MDO) systems, a decisive step has been taken for the production of fully recyclable mono-material films - enabling the Russian film manufacturer Grand-Master to position itself as a pioneer in the domestic market.

Full PE films of the highest quality

MDO technology is based on mono-axial film stretching and opens up the possibility of specifically adapting and improving the properties of the end product. Various mechanical and optical properties or film thickness can be modified in this way. This is the decisive component for the production of high-performance mono-material composites made of polyethylene, which can be fully recycled after their original use and reused in the circular economy without material loss. For a long time, the necessary properties could not be achieved: "Until now, composites had to be produced from different materials in order to achieve the desired product properties. However, these are never completely recyclable or can only be recycled with difficulty. With our MDO technology, films can be produced in the required quality. This innovative technology for the production of flexible packaging is an important step towards future-proof and sustainable full PE solutions. These mono-material solutions are a global trend right now," explains Ivan Evseviev, Sales Manager at Hosokawa Micron St. Petersburg (Hosokawa Alpine's branch in Russia). This also convinced the customer Grand-Master, who is located near Moscow. The renowned manufacturer has been active on the market for over 15 years with high-quality multilayer blown films for printing and lamination, thermo-shrink film and films for the agricultural sector and has been able to establish itself firmly in the Russian premium segment. Grand-Master's machinery is now complemented by a line from Augsburg, as the topics of full PE and sustainability have been at the top of the company's agenda for some time, as Mikhail Ryazanskiy, sales manager at Grand-Master, explains: "We are firmly convinced that the future belongs to such environmentally friendly technologies. That's why we didn't hesitate to include full PE solutions in our portfolio - even though this makes us absolute pioneers in Russia. The 5-layer blown film line with MDO from Hosokawa Alpine is the best possible choice for this."

One system, versatile possibilities

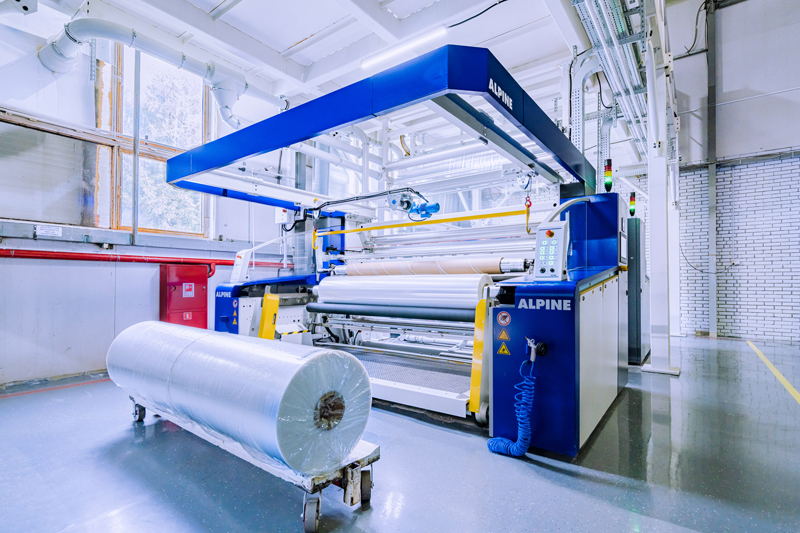

The high-tech blown film line can be operated with or without MDO, giving the customer maximum flexibility in the production of different films: one line enables the production of blocked, unblocked and unfolded MDO films. Grand-Master produces films for a wide range of applications such as twist wrap, breathable films, shrink films and full PE laminates. A special feature of the Hosokawa Alpine line is the unfolding device. The line enables Grand-Master to serve different markets and to react to market developments without major line changes. Alpine's innovative blown film technology is a basic prerequisite for the production of stretched film at the highest quality level. A net lay-flat width of 2,600 mm enables production of two panels of 1,300 mm each per winding station without MDO or two panels of 1,175 mm each with Alpine MDO. For optimising the stretched full PE films, the machine is equipped with Hosokawa Alpine's TRIO technology ("Trim Reduction for Inline Orientation"). This significantly improves the flatness and the MDO film is optimally prepared for lamination or printing. TRIO also ensures significant material savings in edge trim waste and thus maximises economic efficiency. In addition, there is a flexible gap adjustment in the MDO. This enables flexible adjustment of the stretch nip to the respective application, thereby significantly reducing the neck-in and thus the use of resources. The customer Grand-Master is satisfied with the result, as Mikhail Ryazanskiy explains: "With the MDO line from Hosokawa Alpine, we can not only produce materials that are currently in demand, but we are also equipped for the sustainable full PE packaging of tomorrow.“

Hosokawa Alpine

Hosokawa Alpine AG is a worldwide leading and innovative machine and system manufacturer with headquarters in Augsburg and a branch in Leingarten. The company also has several subsidiaries in Germany and abroad. The core competence of Hosokawa Alpine lies in the business field of mechanical process engineering with the production of machines and systems for the preparation of powders, granulates and bulk materials as well as in the business field of film extrusion with systems for the production and finishing of blown films. The company employs around 820 people and generated annual sales of around 220 million euros in the 2020/2021 financial year. The company's export quota is around 80 percent. Since 1987, the company has been a 100% subsidiary of the Japanese Hosokawa Micron Corporation.