SML has joined forces with its partners Sukano AG and Kiefel Packaging B.V. The result of their common R&D is a C-PET light cup that combines transparency and recyclability as well as suitability for thermoformed hot-filling or microwavable products. Further advantages include short cycle times during thermoforming and a high stiffness. The newly developed C-PET light can thus be a reasonable option for manufacturers looking for an economic and easy-to-recycle alternative to PP and PS.

Transparency for recyclability

“Because easy recyclability is becoming increasingly important, we opted for a transparent C-PET solution at an early stage of our joint research and development work” says Max-Phillip Lutz, Product Manager at SML. Compared with other coloured PET or PP and PS products, the recycling process of C-PET light is considerably easier. C-PET light film can be smoothly reprocessed in existing facilities together with other post-consumer or post-industrial PET materials.

Alternative to PS and PP

In general, C-PET is temperature resistant up to 220°C. However, this is not necessary for many applications and limits the output in thermoforming. In contrast, C-PET light was developed to withstand a maximum temperature of 100°C. The new C-PET light enables the manufacturing of transparent thermoforming products for hot-fill applications up to 100°C at output volumes comparable to those of conventional A-PET processes. Especially the shorter cycle times during thermoforming are an economic advantage compared with conventional C-PET.

Adjusting process technology

All three project partners shared their specific expertise and their profound experience in their respective areas in order to improve every single step in all processes. The main technical challenges were to find the optimum dosage for the additives, to adjust the formulations and the process technology during film production, and to find the right parameters for the thermoforming process.

Key characteristics of C-PET light:

- Suitable for transparent applications

- Short cycle times and high output compared with C-PET

- High stiffness compared with PP

- Recyclable

About Sukano:

Sukano AG is a global specialist in the development and production of additive and colour master batches and compounds for polyesters, biopolymers, and specialty resins. The company is driven by expertise and uses its technical knowledge to develop innovative products and services that go into packaging and durable goods, building and construction, and medical and textile markets. www.sukano.com

About Kiefel:

Kiefel develops and produces high quality machines for processing plastics, recycled and bio-based materials as well as natural fibers. Kiefel's customers include well-known manufacturers from the medical engineering & pharma, refrigerator, and packaging industries. With its own technology and material centers, the company offers turnkey solutions and provides support in partnership from product development through machines and tools to service. Kiefel and its subsidiaries in the Netherlands and Austria employ around 900 staff and has a global presence thanks to sales and service teams worldwide. www.kiefel.com

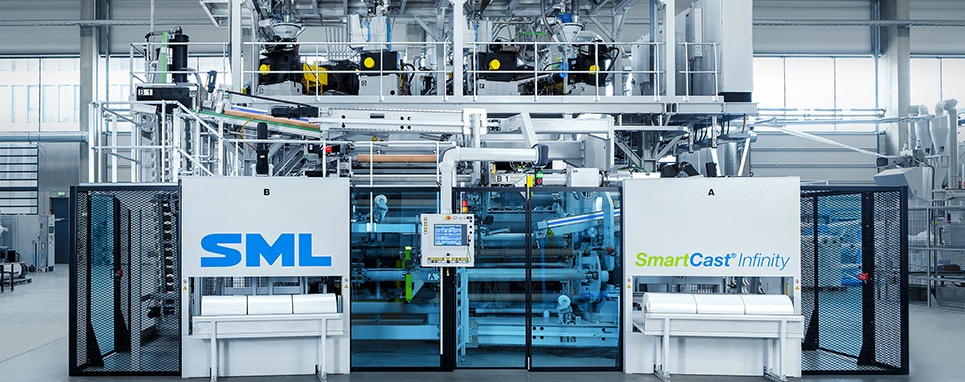

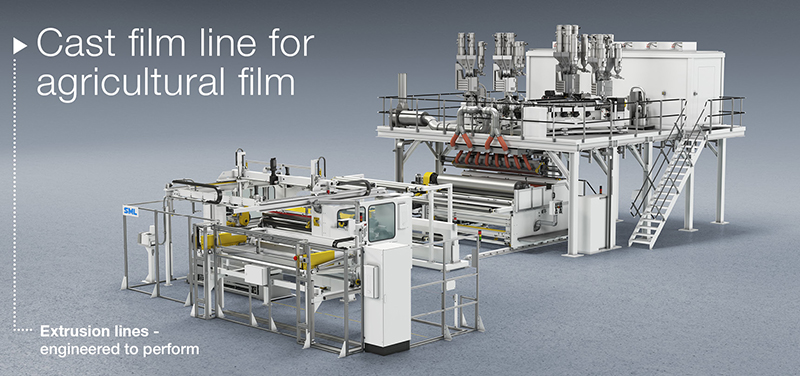

About SML:

SML is a manufacturing company specialising in plastics processing machinery. It is a global market and technology leader in manufacturing high-end extrusion lines. Products manufactured on machinery from SML range from packaging films and textile yarns to medical applications to laminates and compounds. The company’s core strengths include detailed engineering and automation, application technology, and global service. The research and development efforts of SML are currently focused on increasing capacity and productivity, lowering energy consumption, and helping to advance recyclability towards a circular economy. www.sml.at