A world without yarns, fibres and nonwovens is unthinkable. High-quality fibres form the basis for textiles and numerous other products – but their manufacture requires the utmost precision and compliance with strict technical and legal requirements.

Fibre Extrusion Technology (FET), based in Leeds (UK), is a leading British manufacturer of process technology and equipment for the chemical yarn and fibre extrusion industry. Since its foundation in 1998, FET has been developing, producing, installing and maintaining highly specialised extrusion lines for customers worldwide.

All FET systems are custom designed. The company supplies extruders and complete downstream equipment on a laboratory, pilot or turnkey production scale for applications including:

- Melt spinning systems for monofilaments and multifilaments

- Meltblown and spunbond systems for nonwoven structures

- Wet spinning systems for filaments and fibers

FET carries out development work, tests and customer trials at its own state-of-the-art fibre development centre with integrated test laboratory. Typical applications are:

- Resorbable polymers for use in medical devices

- New types of special fibers made from exotic and difficult-to-process polymers

- Sustainable polymers such as biodegradable and compostable materials

- Textiles for a wide range of composite materials

- Functional textile materials as well as a wide variety of nonwovens

The areas of application for yarns, fibres and nonwovens produced using FET systems range from clothing and functional textiles to hygiene products, upholstery and mattresses, and even applications in the construction industry. In medical technology, absorbable and non-absorbable polymers are used, for example, in surgical sutures and implants. Further processing is carried out by customers or specialised service providers, with sterilisation mainly using ethylene oxide or gamma irradiation.

Fiber development center

A key factor in FET's success is its close cooperation with technologically demanding customers. Following extensive investment, the company opened its new Fibre Development Centre (FDC) in 2023. The two-storey building houses state-of-the-art fibre extrusion systems and is used for the joint development of scientifically sound and practical solutions – in cooperation with customers, raw material manufacturers and research institutions. Almost all relevant material types are examined and processed here.

Extruded yarns and fibers for medical applications

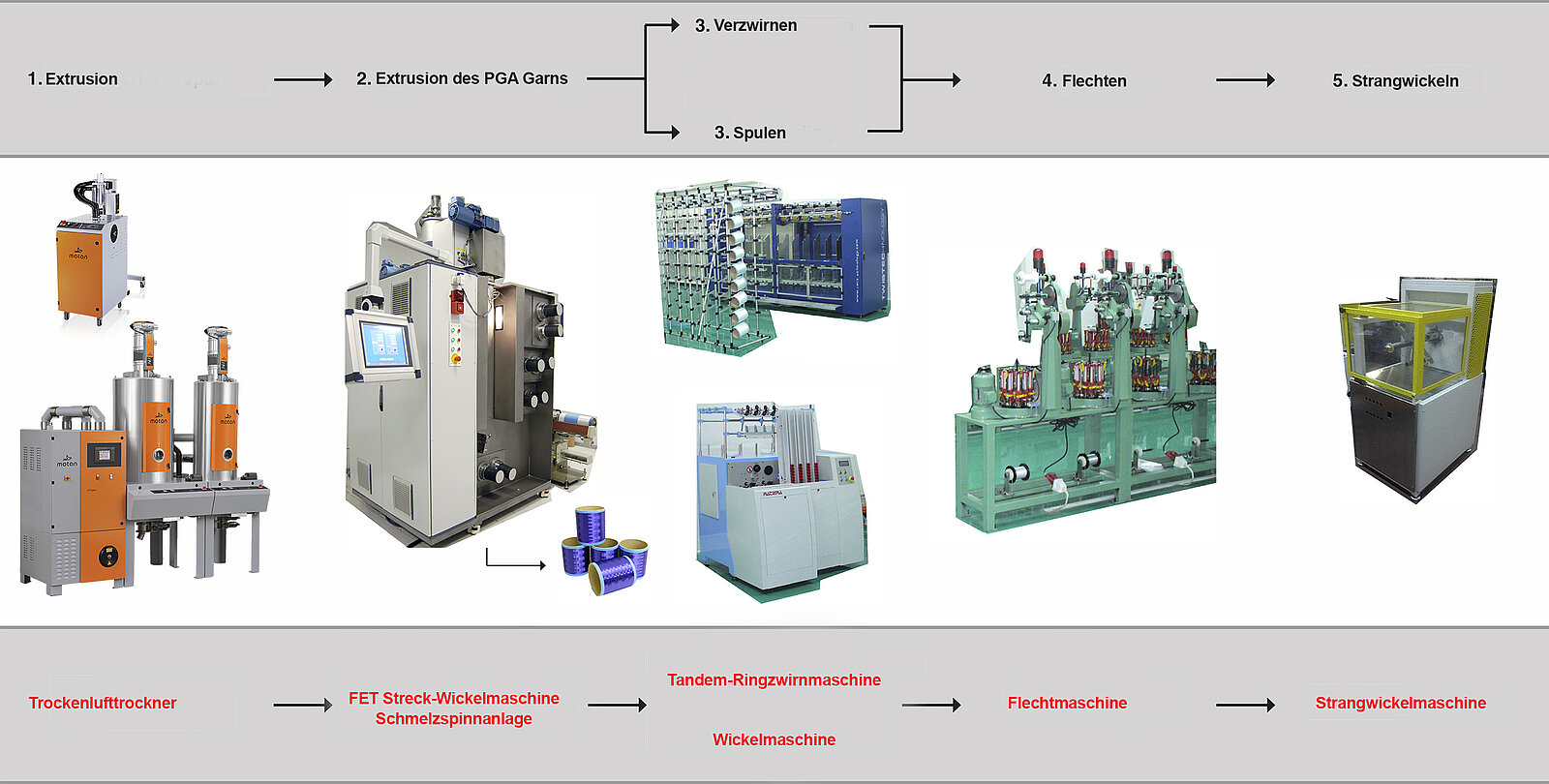

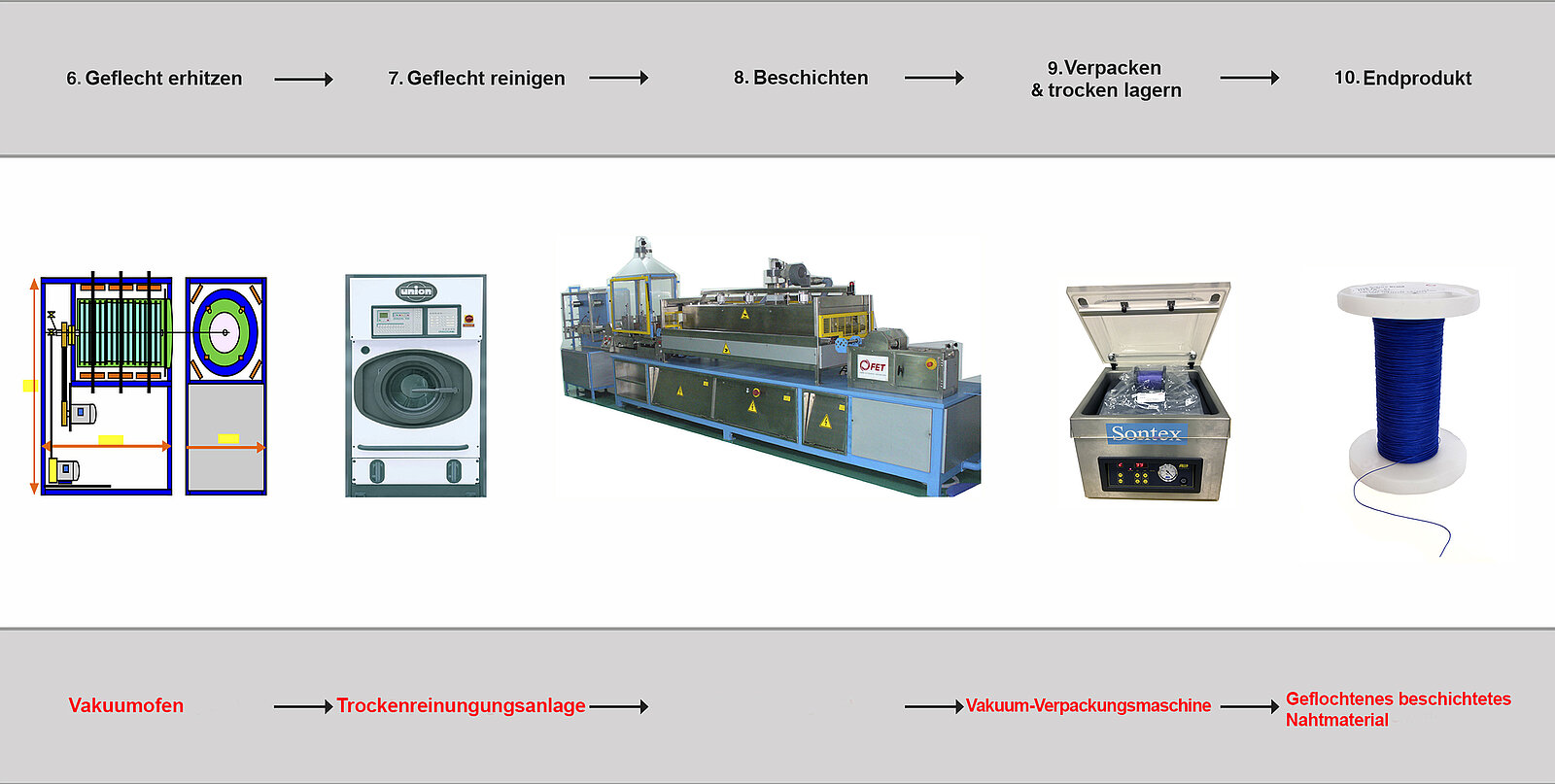

A milestone was reached in 2012 when a leading medical technology manufacturer sought a turnkey solution for processing resorbable polymers for surgical suture material. Together with Motan Colortronic LTD UK and raw material suppliers, FET launched an extensive development project.

Key requirements included:

- Extremely low and uniform moisture content of the material

- Additives must be dosed constantly and with an accuracy of 0.02%, even with different extruder throughputs

- Product-specific tensile strength and length elasticity

- The manufactured products must be biocompatible and free from impurities

In addition, there were strict regulatory requirements, particularly regarding filament thickness according to the European Pharmacopoeia (EP) and USP classification. At the same time, economic aspects also play a role, as the polymers used can cost over £2,500 per kilogram.

As conventional melt spinning processes were unsuitable, FET developed a modified process. Working closely with Motan Colortronic, innovative solutions were developed, including improved material drying, high-precision gravimetric dosing, energy-efficient processes and fully integrated, automated control.

These developments resulted in production-ready systems that have since been successfully used by FET customers worldwide. Motan Colortronic supplies the complete material preparation and supply system, including dosing, conveying and drying systems.

Material diversity and process reliability

Today, numerous polymers are used worldwide for medical applications, including PLA, PGA, PCL, P4HB, PDO and PTMC. They are characterised by high biocompatibility, low toxicity and defined degradation rates. To date, FET has processed over 70 different types of polymers as mono- and multifilaments as well as nonwovens – including materials from sustainable sources.

Precise drying is particularly important, as many of these polymers are extremely sensitive to hydrolysis. FET therefore relies on specially developed extruder and screw combinations as well as extrusion under an inert atmosphere to ensure consistent product properties.

Material preparation and supply

The wide variety of materials also places high demands on peripheral technology. Depending on the application, Motan Colortronic dryers with dew point and air volume control, automatic or manual conveyor systems, and gravimetric dosing and mixing systems are used. FET attaches great importance to the use of proven standard components for safe and reliable operation.

In laboratory and pilot plants, drying is often carried out in batches. The material is then transported to the extruder in hermetically sealed glass containers to prevent contamination. For this purpose, FET has developed a special quick-release fastening system that can be adapted to standard containers.

Fibre Extrusion Technology LTD

Fibre Extrusion Technology LTD (FET) is a leading supplier of state-of-the-art process technology and equipment for the manmade fiber and fiber extrusion industry.FET offers in-depth expertise and know-how in design, process engineering, electronics, manufacturing and customer service. FET offer bespoke and standard installations ranging in value from £300,000 to £3 million. With installations in over 35 countries, FET is geared to work in the global market and with different cultures.

Fibre Extrusion Technology Limited

Units F & G Treefield Industrial Estate

Gelderd Road

Leeds

LS27 7JU, United Kingdom

www.fetuk.com

The motan-group

The motan group based in Constance was founded in 1947. As leading provider for sustainable raw material handling, they operate in the areas injection moulding, blow moulding, extrusion and compounding. Innovative, modular system solutions for storage, drying, conveying, dosing, and mixing of raw materials for the plastics manufacturing and processing industries are part of the application orientated product range. Production takes place at different production sites in Germany, India, and China. motan distribute their products and system solutions via their regional centres. With about 600 employees currently, a yearly turnover of roughly 137 million euros is achieved. Because of their network and long-standing experience, motan can offer their customers what they really need: Individually tailored solutions with real added value.

motan gmbh

Otto-Hahn-Strasse 14

61381 Friedrichsdorf

www.motan-group.com

Motan-Colortronic Ltd

Motan-Colortronic Ltd is part of the motan group, founded in 1949, which manufactures high quality ancillary equipment for the granule and powder plastics processing industry and has a worldwide customer service network. Customers in the UK and Ireland include Epson, Visteon, Toyota, Intier, Bespak, Oral B, DHM, Honda and Becton Dickinson.

Motan Colortronic Ltd supports its products with regionally based, highly skilled service engineers and a comprehensive UK spares inventory, including Regloplas and Herbold.

Motan Colortronic UK Ltd

Matilda House, Carrwood Road

Chesterfield

Derbyshire

S41 9QB, United Kingdom

www.motan-colortronic.co.uk

![[Translate to English:] [Translate to English:]](/fileadmin/redakteur/Kunden/IBD_Wickeltechnik/News/2026/2026-02-06/2026-02-11.jpeg)