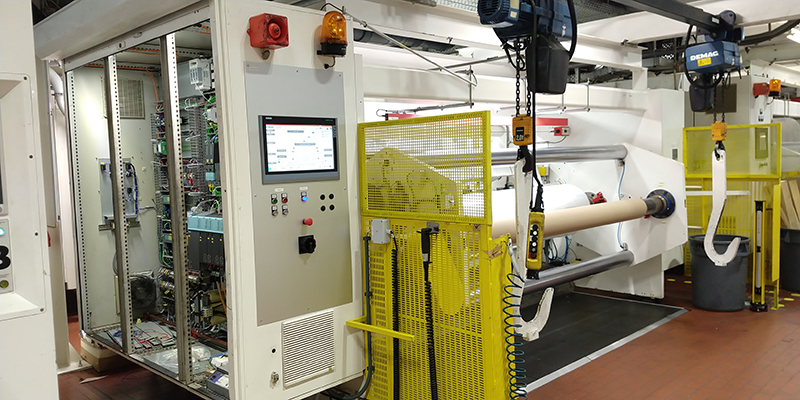

DK-HV specialises in offering "turnkey" solutions for extensive and complex retrofits and installations at a fixed price.

"Turnkey" means from one source: DK-HV project management including commissioning and coordination of the mechanical and electrical installation work by our partners.

Example of projects carried out:

- PLAST-CONTROL

- Replacement of old machine controls (Siemens, EXTROL) with PLAST-CONTROL NAVIGATOR

- Upgrade conveying system and gravimetric dosing units

- Upgrade IBC control and width measurement and control

- emperature zone control incl. current measurement and load shedding

- WEMA

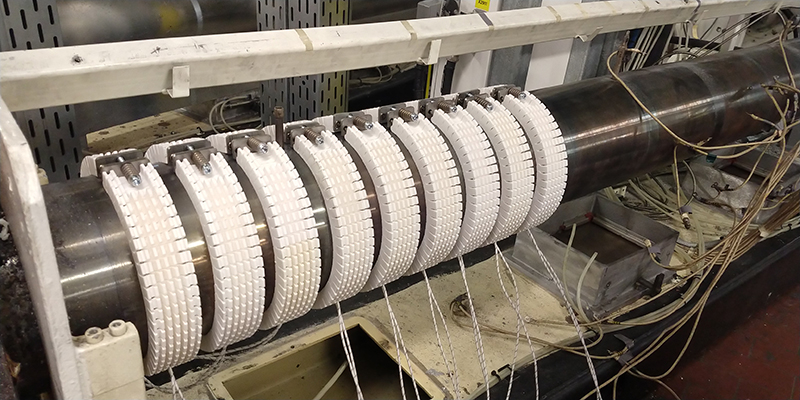

- Replacement of ALU heating bands with heating bands from WEMA

- New blowers incl. brackets

- New covers for extruders

- Lebbing

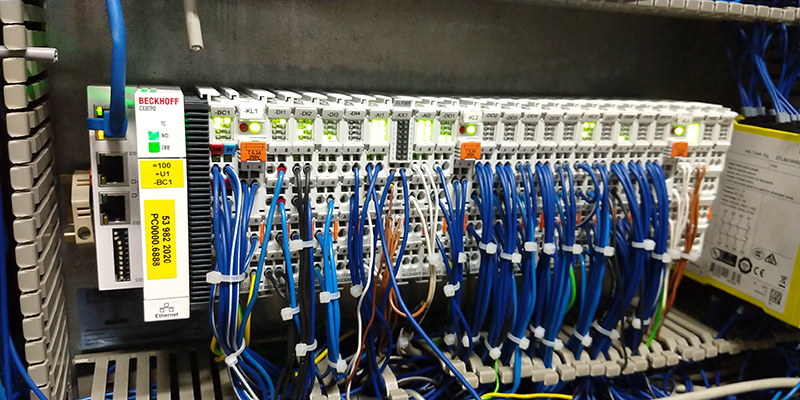

- Installation and commissioning of new frequency inverters incl. mounting plate and associated motors

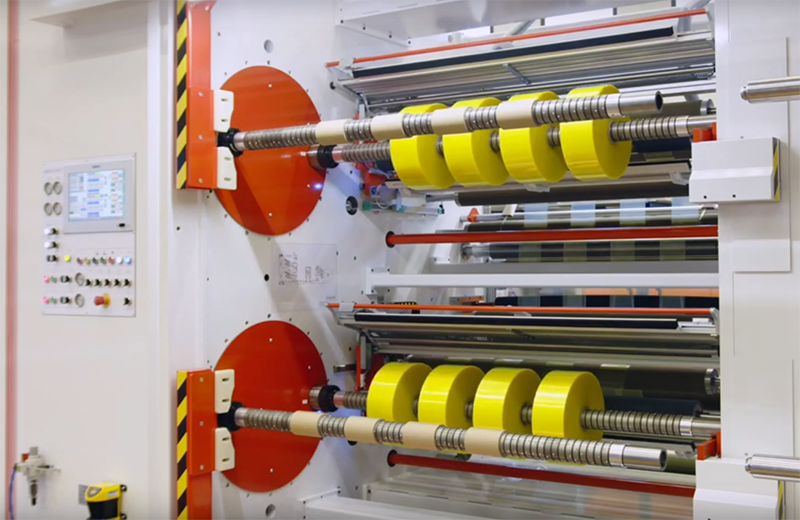

- Retrofit winder: New drive technology (frequency converter, motors) and new software control

- Current safety standard produced on the complete system incl. winder

- DK-Handelsvertretung

- Mechanical installation

- Electrical wiring incl. removal of old cables

- Project management

- Our team on site

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/user_upload/Banner_1-04_Kopie.jpg)