The launch of the 'eSERIES' in 2022 followed by its consistent promotion throughout 2023 stands out as one of the most notable innovations by GOEBEL IMS in recent years.

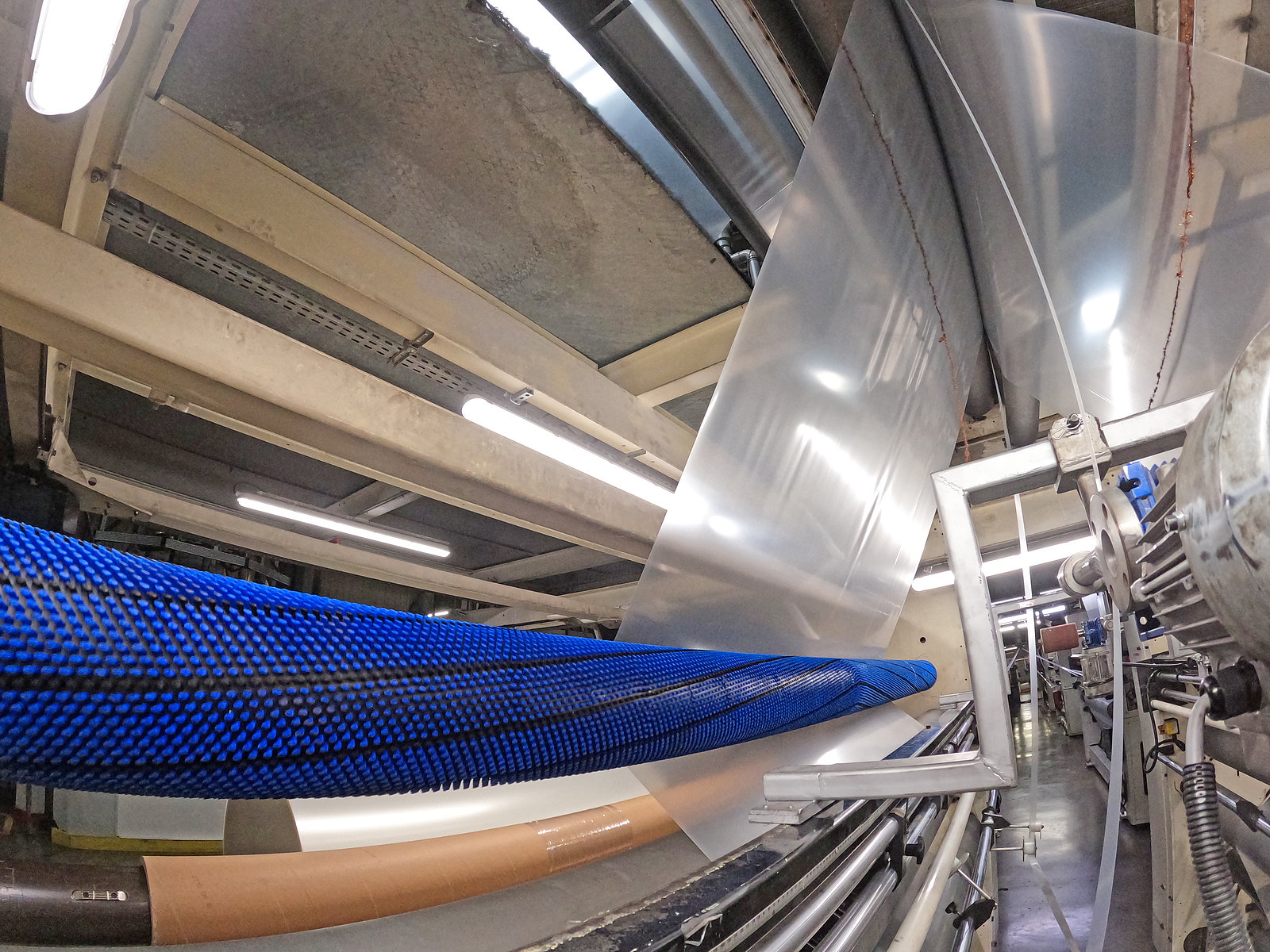

With special attention to electricity consumption and design, GOEBEL IMS's extensive 170 years of experience in building machines has enabled the creation of a new range of fully electric slitter rewinders for the film market. These solutions give customers many competitive advantages including enhanced energy efficiency – up to 25% over hydraulic machines, simplified maintenance, and increased productivity. They also maintain a high technological profile, ensuring superior performance and quality of the finished reels.

The eSERIES comprises four machines types, ranging from the widest machines for the primary industry (eMONOSLIT and eMONOSLIT GIANT) with a working widths up to 12000 mm, passing through the unparalleled efficiency of eINTERSLIT, and culminating in the eXTRASLIT, the most compact machine with a working width of 3800 mm.

“The market has responded positively, as confirmed by the sales” said Marino Ferrarese, Group Sales, Marketing & Service Director.

In addition to designing cutting-edge machines, GOEBEL IMS is capable of intercepting and consequently meeting the market's demands. As we all know, the electric vehicle market is growing and will continue to do so in the coming years, therefore GOEBEL IMS's extensive machine portfolio also includes a machine for slitting ultra-sensitive materials such as battery separator film based on wet processed BOPE.

A Look Ahead to 2024

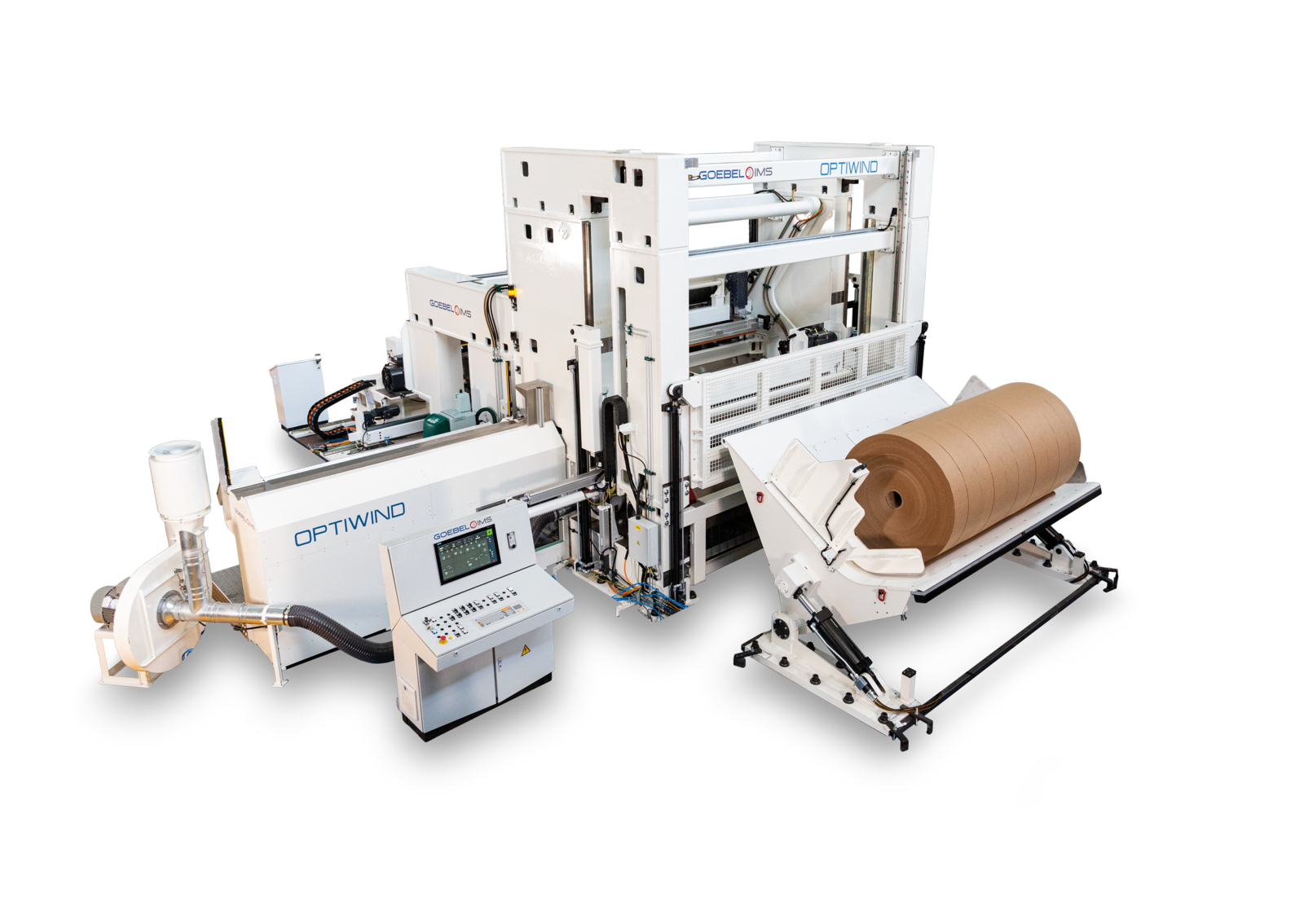

2024 will be a challenging year for our paper business unit. Starting from participation in PAPEREX in India in December 2023, up to the presence at drupa 2024, we will showcase our best sellers such as RAPID, the machine for precise slitting of narrow reels, while maintaining focus on our larger machines like OPTIWIND, the ideal machine for wider cutting, and the T2, the optimal solution for the aseptic market.

“The development of the new electric range for the film sector and the opening to new markets, for the paper business but in general for all our segments and brands, has strengthened our confidence in the future” continued Marino Ferrarese.

Additionally, we are in the final phase of constructing our new building at the production site in Calcinate. The expansion project has been ongoing since March 2023. This new facility will be dedicated to assembly activities and marks an important step in our company's growth, signaling the beginning of new projects and developments. The facility has been built with particular regard to the environment, emphasizing IMS TECHNOLOGIES' commitment to sustainability. The installation of photovoltaic panels will significantly reduce environmental impact and CO2 emissions, contributing to renewable energy production. The solar plant, which has also been installed on the roof of the existing building, is capable of generating a total capacity of 350 kWp.

This step not only moves us closer to energy independence but will also reduce the emission of approximately 200 tons of carbon dioxide annually, equivalent to planting 10,200 fully grown trees.

Our commitment to sustainability is tangible, and we aim to double the installed capacity to further increase environmental benefits.