During the Chinaplas event in Shenzhen (April 15-18), Macchi invited a select group of customers from across Asia to visit its latest installation, located directly at the customer's site in Guangdong province.

The installation is at the facility of Guangdong Airbaker New Material Co., located on the outskirts of Zhuhai. Established about a decade ago, Airbaker initially focused on producing air cushion bags for protecting goods, a market that quickly grew alongside the rise of online shopping. As the company’s production quality gained recognition, major European end-users took notice, prompting Airbaker’s General Manager, Mr. Xie, to explore further development opportunities.

His interest turned to high barrier food packaging films, and after discussions with Macchi and their Chinese partners, Rieckermann, Airbaker decided to invest in a 7-layer line in 2021, featuring a 1800 mm layflat and a production capacity of over 450 kg/h. This line has consistently produced high-quality barrier films for export, leading to a decision in 2023 to purchase a new, more advanced line.

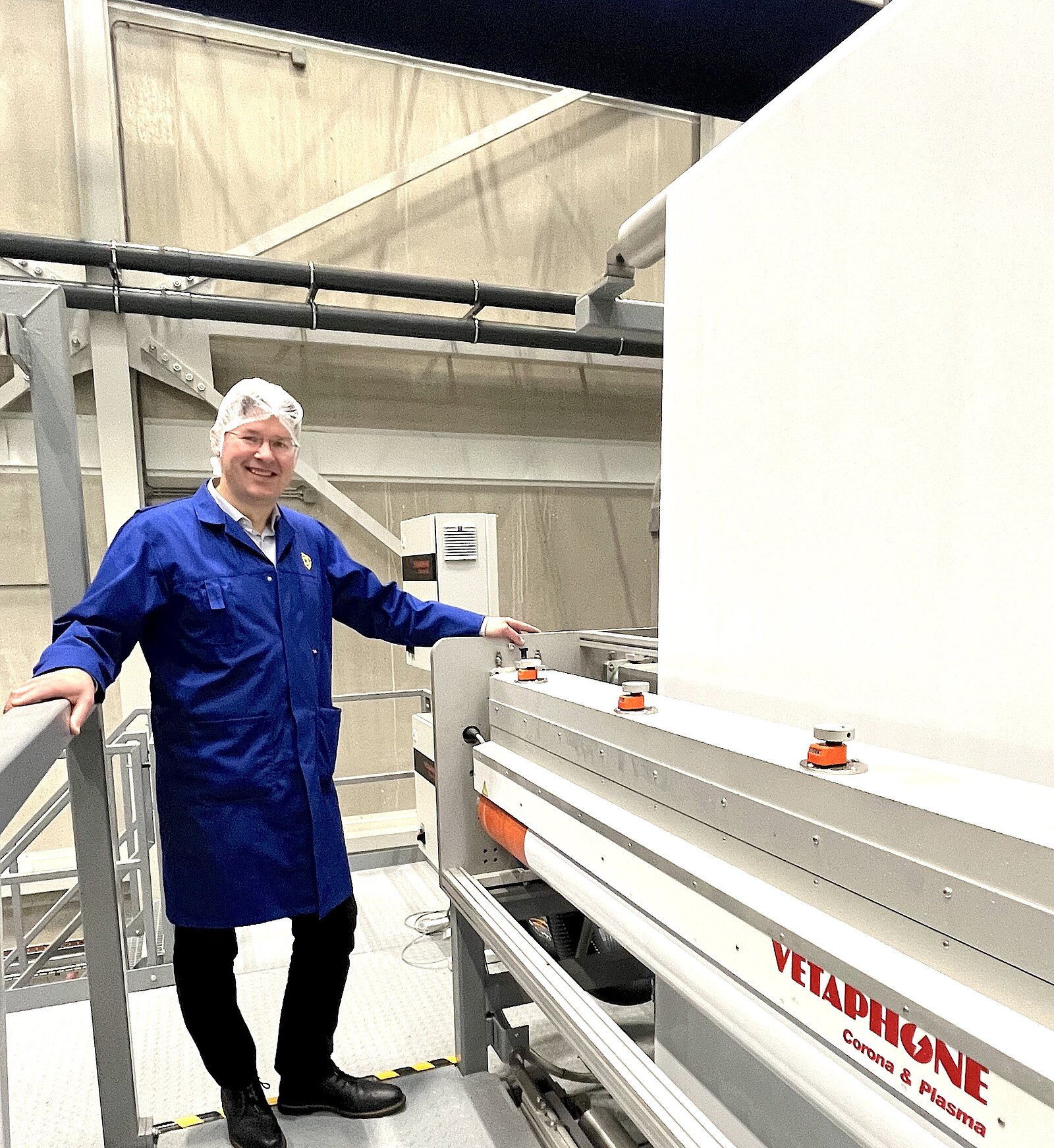

The new line, installed in 2025 , is a 9-layer system with a 3000 mm layflat and a capacity of up to 700 kg/h. It can produce both barrier and non-barrier structures. Featuring a 650 mm die diameter on the MACCHI TE710 die head, designed to process both polyolefin and barrier resins, the line includes two 65/30 extruders for the skins, and the other extruders are 55/30. This configuration allows for the production of both symmetric and asymmetric structures without curling, as well as full PE films.

The line is equipped with Macchi’s carbon fibre air ring, incorporating the K Design VARIOcool profile adjustment system, and features an 18-meter tall tower (locally manufactured). It also includes the world renowned BO Plus winder, offering multiple winding modes (contact, axial, and mixed) to suit the type of film being produced. Additionally, a DOTECO 4-component gravimetric dosing system and an NDC nuclear sensing head for profile scanning ensure high productivity and top-quality film production.

Following the Chinese Spring Festival, the new line was fully commissioned, and Mr. Xie allowed Macchi to host a group of selected domestic and international customers at the site. Visitors were able to see the new line in action alongside the previous 7-layer line, both producing high-quality barrier and non-barrier films for a wide range of applications. The tour also highlighted the impressive new factory, which was built in record time.