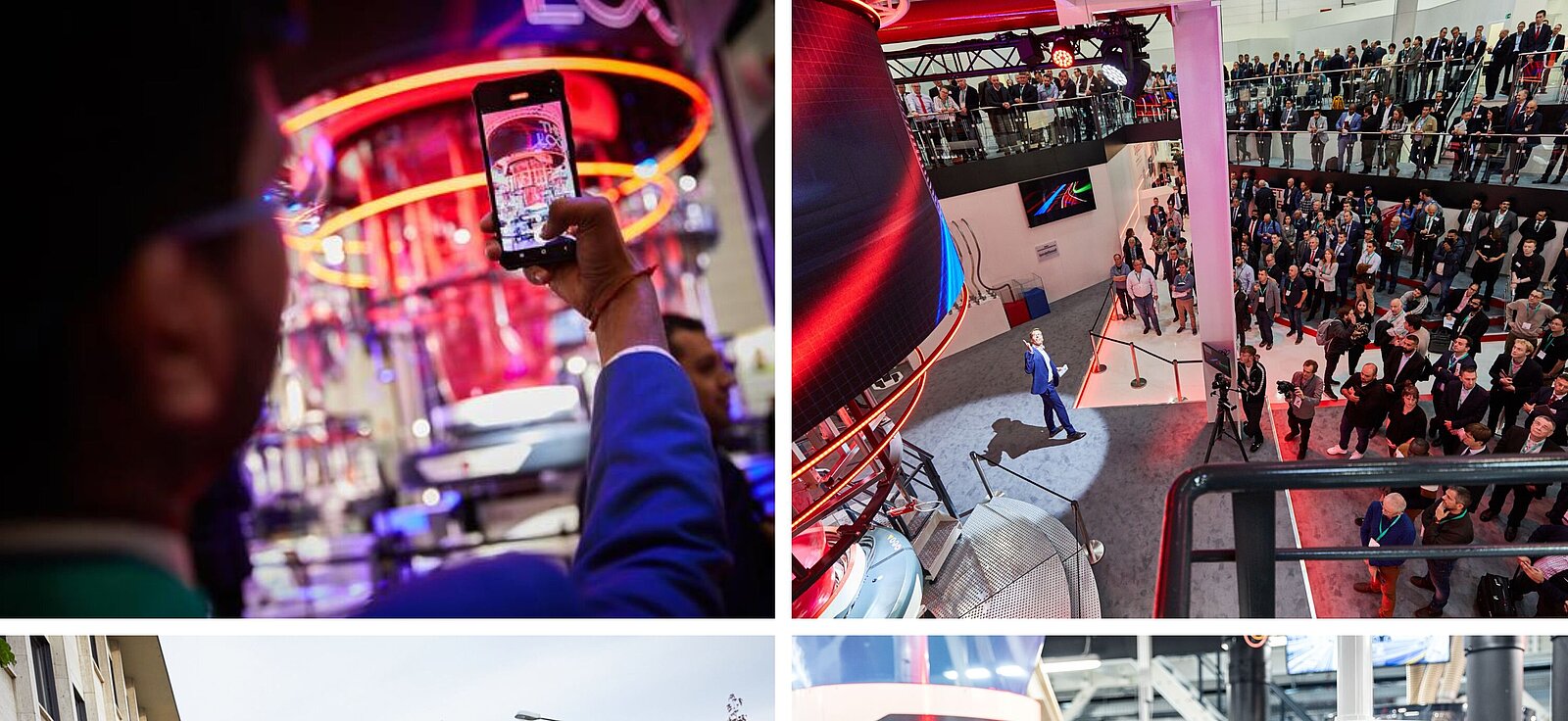

On the occasion of the upcoming K2025 trade fair, Macchi will showcase a 7-layer coex line for the production of barrier film.

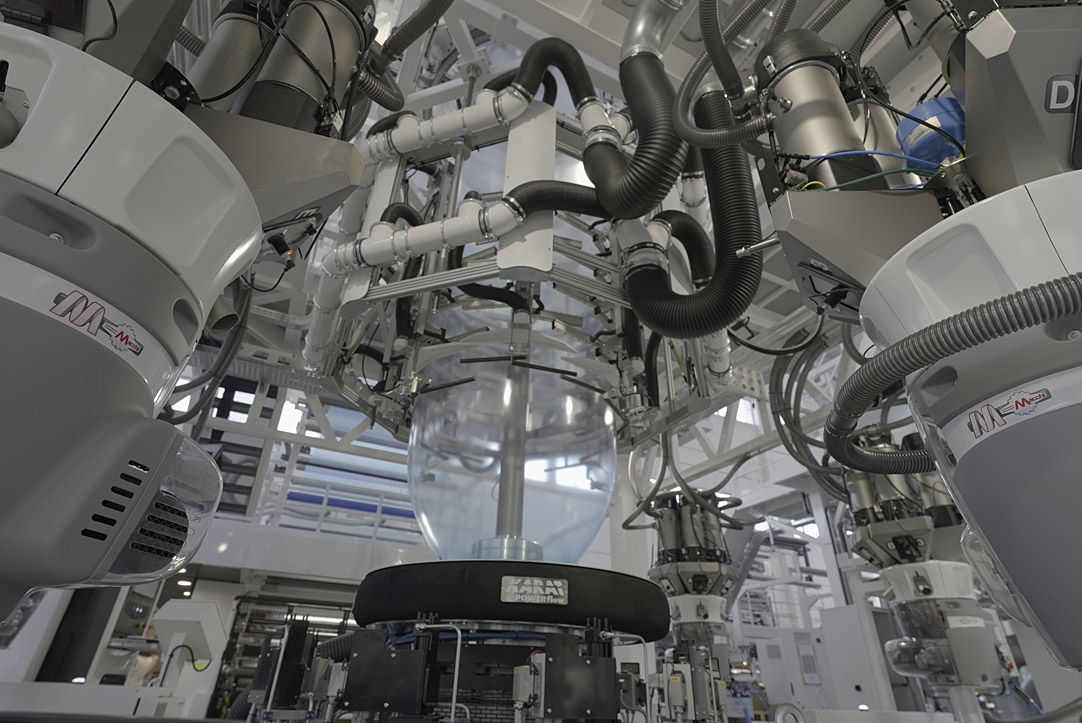

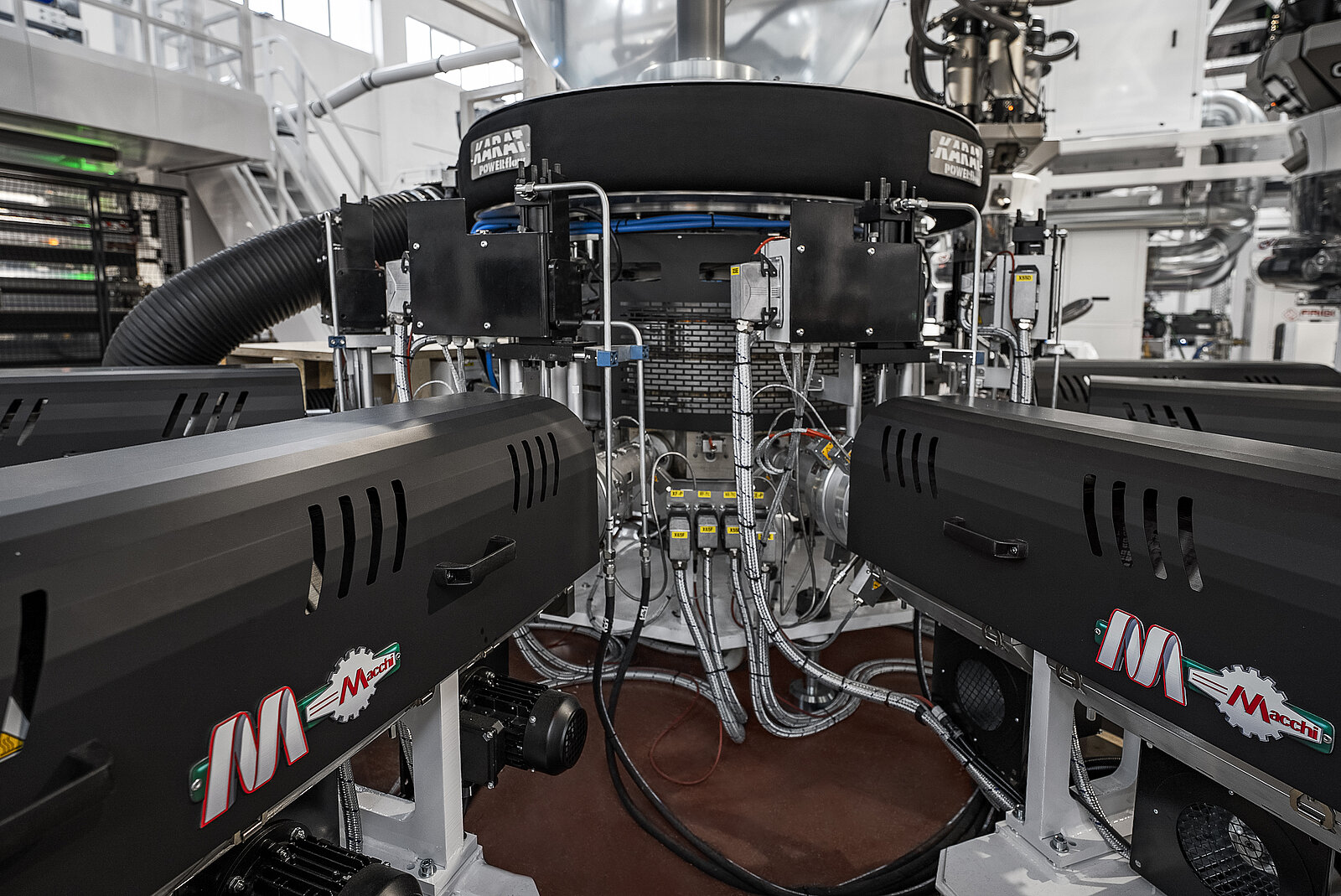

Equipped with four 65/30 extruders for the outer and intermediate layers, and completed by three 55/30 extruders for the adhesive layers and the EVOH layer, this line is capable of an output of up to 600 kg/h with a maximum film width of 2300 mm.

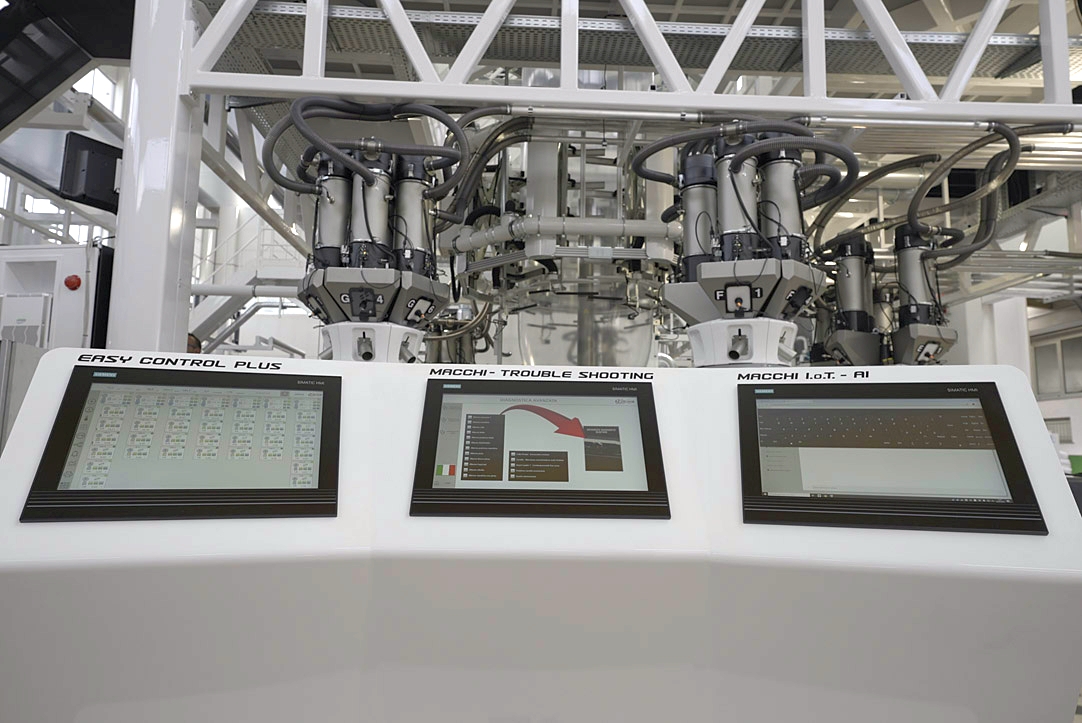

The line will also feature several of Macchi’s latest technological developments, including an upgraded version of the “Easy Control” line supervision system — the long-standing standard across all Macchi lines — now enhanced with an IoT system for production data management and the brand-new AI Assistant, designed to help resolve line operational issues while minimizing downtime.

Further equipment includes the PowerFlow air ring with wax removal system, frost line detector, fume extraction system on the primary bubble guide, and the VarioCool film thickness control and regulation system, which — together with Macchi’s high-precision extrusion die design — ensures extremely tight profile tolerances in very short timeframes. The CentroFreeze secondary bubble guide, equipped with a secondary bubble cooling system, allows for reduced blocking during take-off even under extreme environmental conditions or at high productivity rates.

Finally, the latest version of the Bo Plus winder, equipped with the Smart Load system, enables semi-automatic mandrel loading and reel unloading.

The first focus of this line is productivity: Macchi guarantees a minimum EVOH layer thickness of just 4% of the total film structure, allowing the resulting film to be classified as “mono-material” and therefore fully recyclable. This directly meets increasingly strict green regulations.

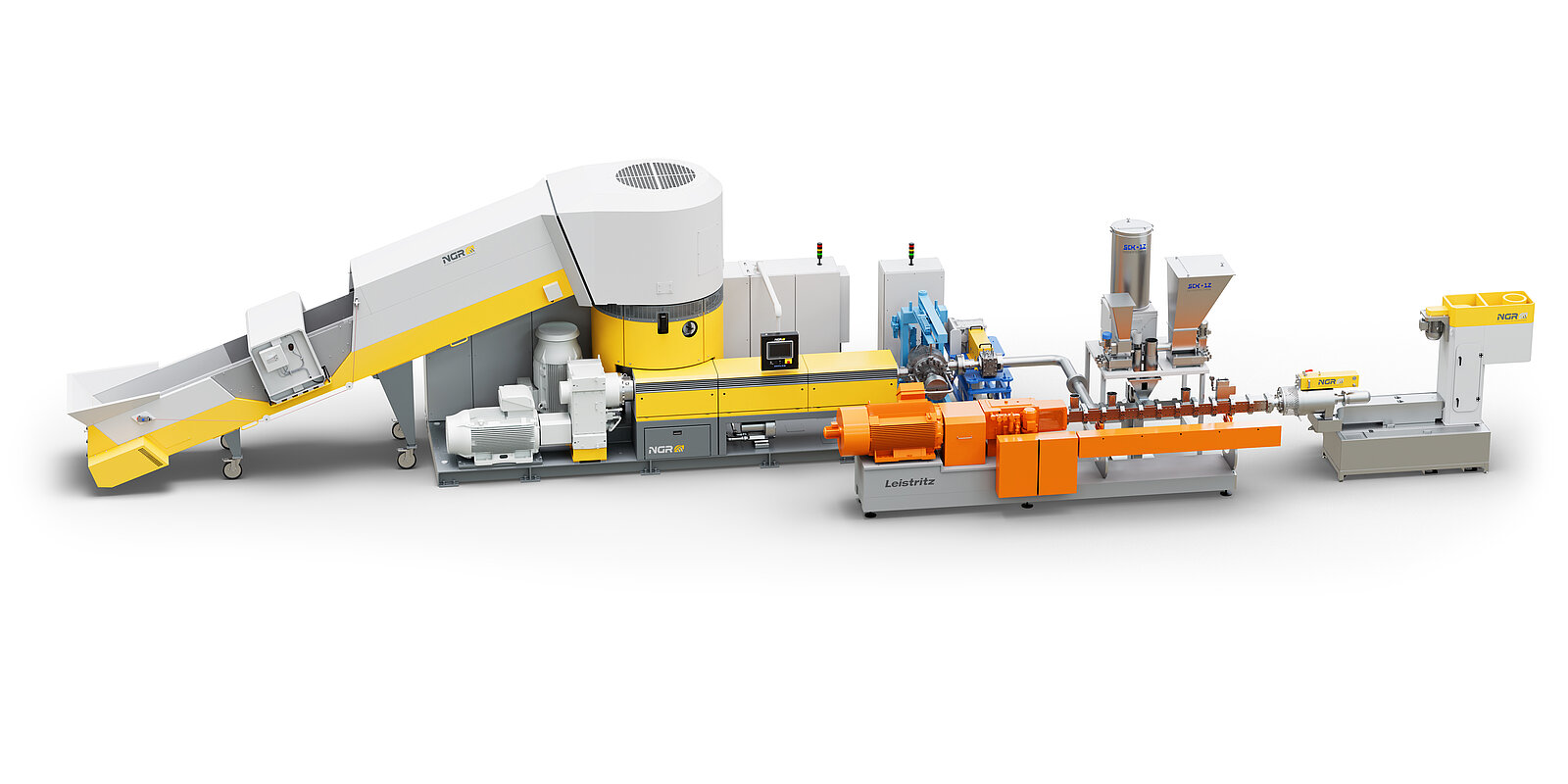

This aspect is fundamental: the growing need to protect the environment through technologies that reduce raw material consumption, allow for easy reuse of packaging, and ensure effective end-of-life recycling, lies at the core of Macchi’s R&D. In recent years, this commitment has led to the development of systems capable of producing films with low environmental impact — whether biodegradable, water-soluble, or recyclable — as well as lines able to process resins with high (up to 100%) PCR content.

The second focus is automation, centered around platforms such as the new Macchi Easy Control Plus system.

Developed on SIEMENS SIMATIC WinCC Unified, Easy Control Plus enables the creation of customizable interfaces, integrates all external utilities, and allows their process data to be saved. Furthermore, its integration with the Macchi IoT system enables real-time monitoring of machine performance and the identification of factors that limit efficiency and productivity.

In addition, the new Macchi AI system, based on generative artificial intelligence technologies, is designed to support operators in daily plant operations. Thanks to its ability to process and interpret comprehensive plant knowledge, Macchi AI acts as a true digital expert, offering direct support for fault diagnosis and alarm resolution, thus reducing machine downtime.

Compliant with the European Union’s NIS2 directive, Macchi’s new line once again meets the needs of processors looking to optimize resin usage according to the products being packaged — while ensuring ease of operation and high productivity, both in terms of quantity and quality.

The flexible packaging market is becoming increasingly competitive: converters are constantly seeking solutions that offer the best protective performance for a wide range of products, while simultaneously reducing production costs, which are traditionally tied to resin use.

It is within this context that the technological evolution of barrier film production lines should be understood: from the early 5-layer structures, the current trend is now toward 7- and 9-layer lines, which not only ensure maximum flexibility in film structure design, but also allow for significant thickness reductions, benefiting both production cost-efficiency and material savings.

Booth 17C20