With increasing requirements on recyclability, interest in mono-materials is rapidly growing. Machine Direction Oriented Polyethylene film – or MDO-PE film – is playing a key role at the production of easy-to-recycle mono-material structures for flexible packaging.

“Due to its properties, MDO-PE film is an ideal solution when it comes to replace PET in PET-PE laminates, which were used for a variety of flexible packaging products as a standard so far”, Elias Mayrhofer, Product Manager at extrusion line manufacturer SML explains. Application areas of MDO-PE film range from mono-material tubular bags for food packaging to side gusset bags, and from sealed bags to different types of pouches.

Straight-forward further processing

MDO-PE film manufactured on SML’s latest cast film lines with integrated MDO unit provide excellent optical, mechanical and barrier properties. The film can be easily laminated to mono-material structures, for example with CPE sealent film on a FlexPack line from SML. “Cast MDO-PE films exhibit excellent printability and have been successfully tested on both Flexographic and Rotogravure printing systems. Metallisation is possible without any complications even with ultra-thin MDO-PE films”, Elias Mayrhofer states.

Wide variety of different film properties

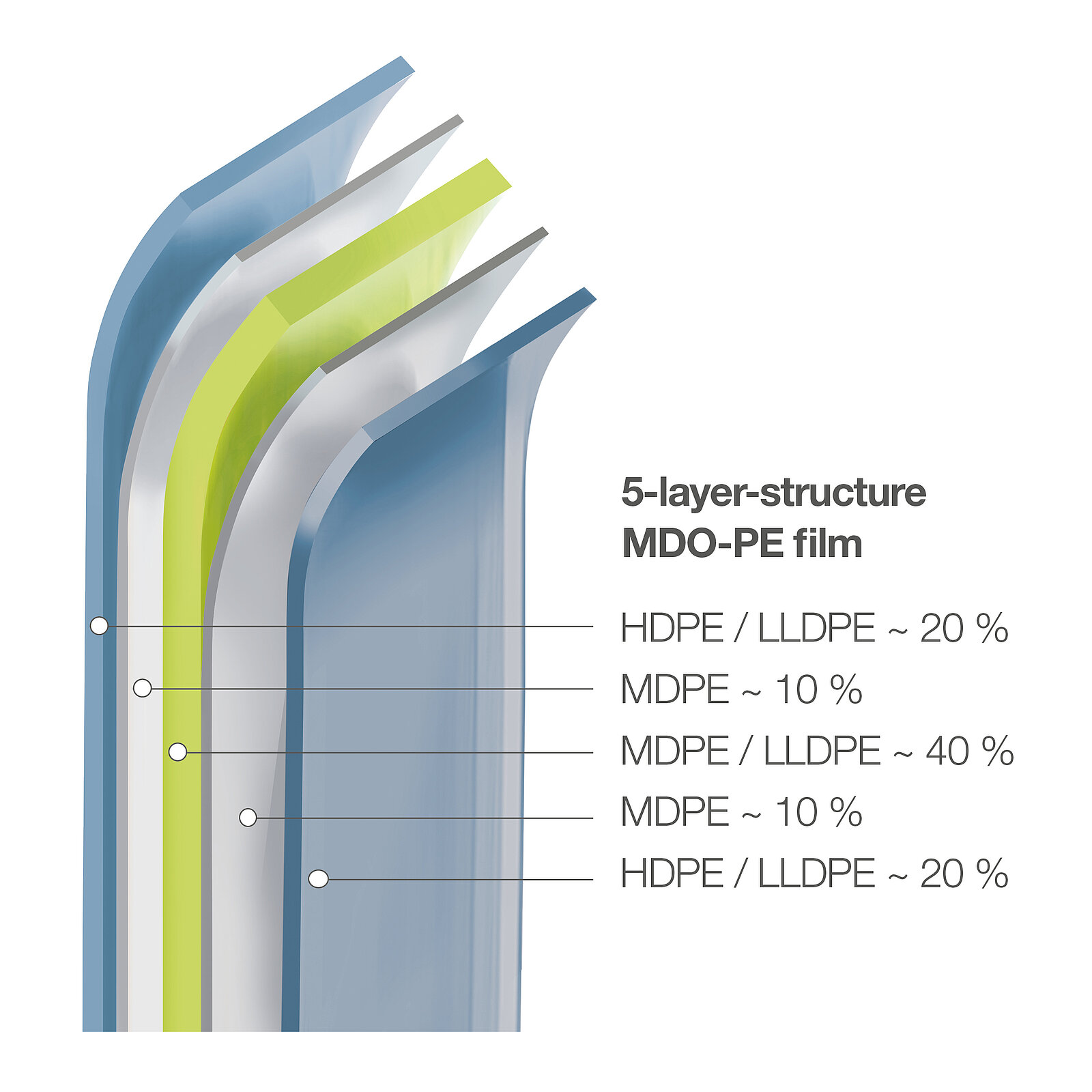

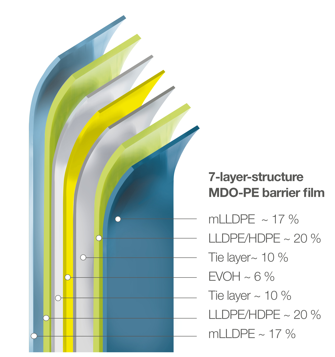

The cast MDO technology allows the production of a wide variety of different types of MDO-PE film:

Ultra-thin film down to 15 µm SML cast film lines are ready to manufacture MDO-PE film as thin as 15 μm. “It goes without saying, that even at the most ultra-thin film the process is completely stable. There are no compromises when it comes to performance, functionality and printability,” Elias Mayrhofer says. A market-ready 15 µm MDO-PE film developed at SML in close cooperation with its polymer supplier and long-term partner Dow Packaging & Specialty Plastics has the following structure:

![[Translate to English:] The picture shows the two managing directors in front of the new building](/fileadmin/_processed_/f/e/csm_Hellweg_2025-0002_NewBuilding_dde86c7720.jpg)