Plastic films are processed at highest speed. High electrostatic charges are generated at the rewinder of the extrusion lines due to the growing film winder. Here, the charge increases enormously. It is imperative that these charges are eliminated to ensure smooth winding and to protect the operating personnel from the high-energy electrostatic discharge. Another aspect is the increase in quality - discharged films do not attract particles and dust. Discharged films do not cause problems for the customer.

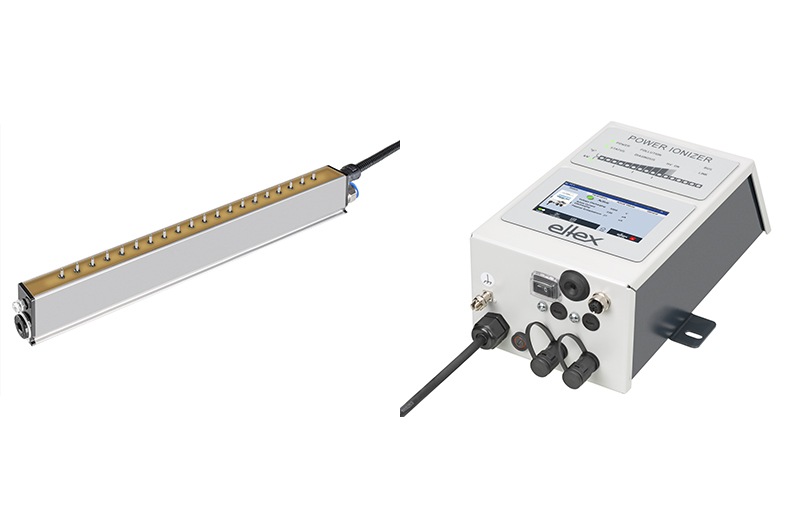

In the application shown, the blown film is cut and wound up after extrusion. Eltex "flexION" discharging bars are installed on each rewinder. In combination with the new Eltex "POWER IONIZER" power supply unit, they ensure perfect electrostatic discharge along the entire length of the film roll.

Discharging bar

Eltex flexION air - the air-assisted discharging bar for longer distances. The patented discharging bar achieves a very high passive discharging effect with its free-standing, air-assisted spring tip. To increase the range, the hollow spring tip is optionally flown through with a small amount of air. This additionally serves to continuously clean the emission tip. The electrode can be operated with or without air support. A minimum air flow of 1 bar is already sufficient for the ions to reach the object to be discharged, even in the vicinity of grounded machine parts. This is particularly helpful in applications with varying distances, such as discharging at a winder.

Built-in POWER IONIZER on the winder.

The Eltex solution for discharging at large or changeable distances.

Power supply

HIGH-END discharge for highest discharge performance The POWER IONIZER high-performance discharging power supply unit impresses with its flexibility. The simple operation, the LED display for visualization of the current values and the integrated function and malfunction monitoring, distinguish the power supply unit. The POWER IONIZER can be operated with all Eltex AC discharge bars, ion blower nozzles and ion blower guns.

Due to various adjustable parameters, lowest residual charges can be achieved. Operation is possible as a stand-alone unit or networked.

Paired with the flexION electrode, this duo offers unprecedented reliable achievement of residual charge targets, especially at large distances such as on extrusion lines.

With a 4-year warranty and the repair option of 10 years, Eltex relies on a safe and sustainable solution with the POWER IONIZER. This applies not only to the power supply unit, but also to the electrodes. With appropriate cleaning, these work reliably for years with low tip burnup. With the new POWER IONIZER, Eltex brings the advantages of AC technology to the "Industry 4.0" world.

.

flexION R60L discharge bar and POWER IONIZER power pack – the high-end discharger from Eltex

Eltex-Elektrostatik-GmbH

Electrostatic Innovations is the slogan of the company from Weil am Rhein in the border triangle of Germany, France, Switzerland. For 68 years Eltex has been a pioneer in electrostatics for industrial applications and is characterized by competent advice from its experts. The wide range of products is developed and manufactured in Germany. Static electricity discharge is the main part of the electrostatics market.

In addition to the field of discharge, Eltex also offers products for electrostatic charging. There it is mainly about fixing something by charging, adhering or changing the properties of a material by charging. In the paper and film converting industry, there are a variety of possible applications. For example, telescoping on the reel can be prevented.

Whatever electrostatic requirements arise from a wide range of industries, Eltex has the right key to solve the problem.

Learn more about Eltex: www.eltex.de/en