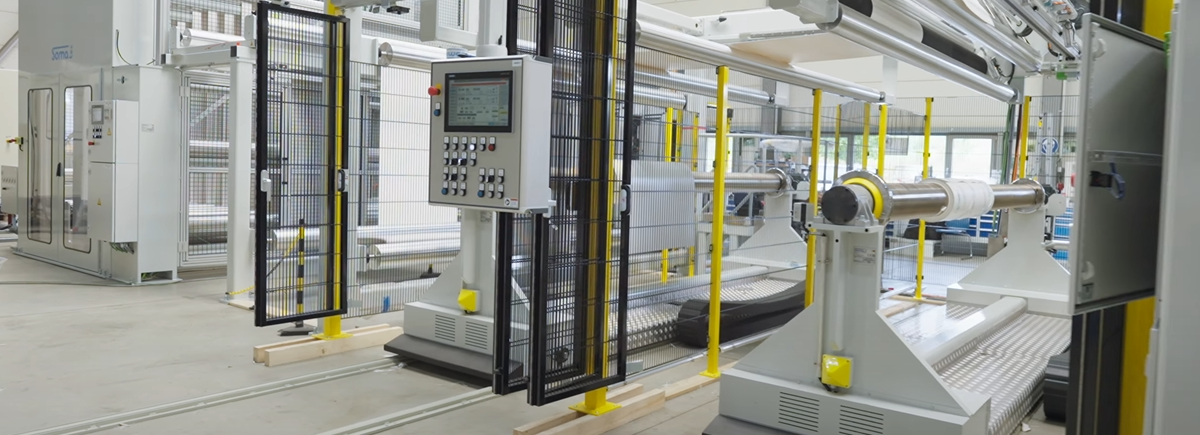

SOMATEC presents a new winding system that has been specially developed for the high demands of processing 12" TPO roofing material. The focus is on precise winding technology, short cycle times and reliable automation for maximum efficiency.

Technical highlights at a glance:

-Material storage with a capacity of 50 m of material – for uninterrupted production processes.

-Transfer unit with semi-automatic roll change on the jumbo reel – reduces downtime and ensures smooth transitions.

-3-station short roll winder with cycle times of less than 1 minute – enables highly productive manufacturing even with short winding lengths.

-Automatic roll and core preparation with core magazine – minimizes manual intervention and increases process reliability.

Added value in practice:

The combination of goods storage, intelligent transfer unit and powerful short roll winder ensures high flexibility and production reliability. The system not only increases productivity, but also ensures consistently high winding quality – a decisive factor in the processing of roofing materials.

SOMATEC thus provides a solution that is both technically impressive and meets the requirements of modern manufacturing.

For more information check out the new video:

Technologievorsprung bei der Verarbeitung von 12" TPO-Dachabdeckungsmaterial