Why Die Head Service at W&H?

Die heads and feed blocks form the heart of your extrusion machine. Their condition has a major influence on the quality and productivity of your film extrusion. Regular maintenance of the die head and feed block is essential to ensure high-quality products.

With our service we help you to clean and maintain the die head and feed block professionally and in a material-friendly manner. Drawing on our experts‘ extensive knowledge, we offer our die head cleaning service not only for W&H machines but also for modules from other manufacturers.

With the goal of keeping the downtimes of your machine to an absolute minimum, we address your specific needs and develop the optimum solution for you. You have the option of cleaning at your premises or at our headquarters in Germany. By making the service at W&H we can guarantee an even more thorough and gentle cleaning thanks to our local pyrolysis furnace. In addition to this it is also possible to repair the die head as we have the spare sparts on hand.

Your advantages

- Increased productivity and secured quality

- Professional, gentle cleaning of die heads and feed blocks

- Qualified repair and overhaul by specialists

- Quick access to production and spare parts during service at W&H headquarters

- Reduced downtimes through on-site service at the customer

- Also for modules other manufacturers

- Optional services: New coating, mechanical polishing, repair or replacement of defective parts, rental of die heads during service time

How does the die head service at our headquarters work?

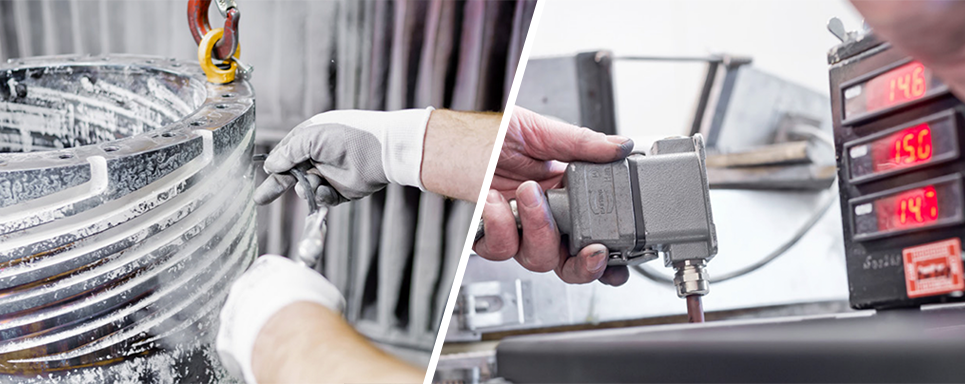

1. Heating & Dismantling

The die head gets heated and dismantled. All individual components are then visually inspected for damage.

2. Pyrolysis

The parts are gently cleaned in the pyrolysis furnace. Afterwards they are carefully cooled in a controlled cooling chamber.

3. Electronic function control

The heating elements and electronic components are checked for functionality and replaced if necessary.

4. Manual cleaning

Chalk residues are removed with compressed air and the individual components plus all accessories are mechanically cleaned.

5. Polishing

All cleaned components are polished by hand and visually inspected for damage. A chemical inspection checks the condition of the coating.

6. Assembly, measurement & documentation

The die will be remounted and all wearing parts replaced. Defective components are repaired or replaced if necessary. All modules are measured and optimally adjusted. Finally, we hand out the overworked die head together with a documentation including detailed pictures of the full service.

![[Translate to englisch:] [Translate to englisch:]](/fileadmin/user_upload/slider_wh_neu.png)