Schwing Technologies GmbH

Thermal cleaning in the extrusion

Demands on film and profiles are continually increasing. Regardless of whether flat or tubular film: they should be as thin and uniform as possible, optically appealing as well as robust and of high quality. The requirements on profiles, for example, for window frames and other construction elements, are increasing. These demands also increase the requirements for the production of profiles and film.

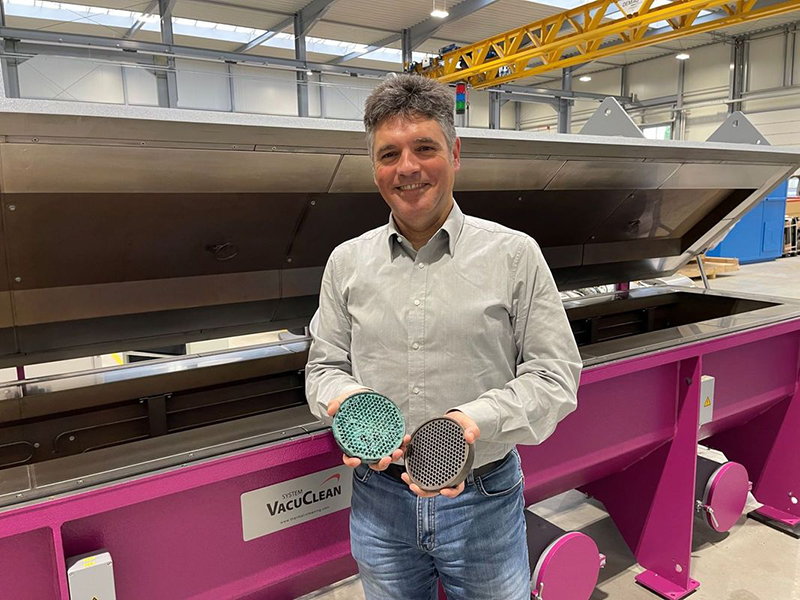

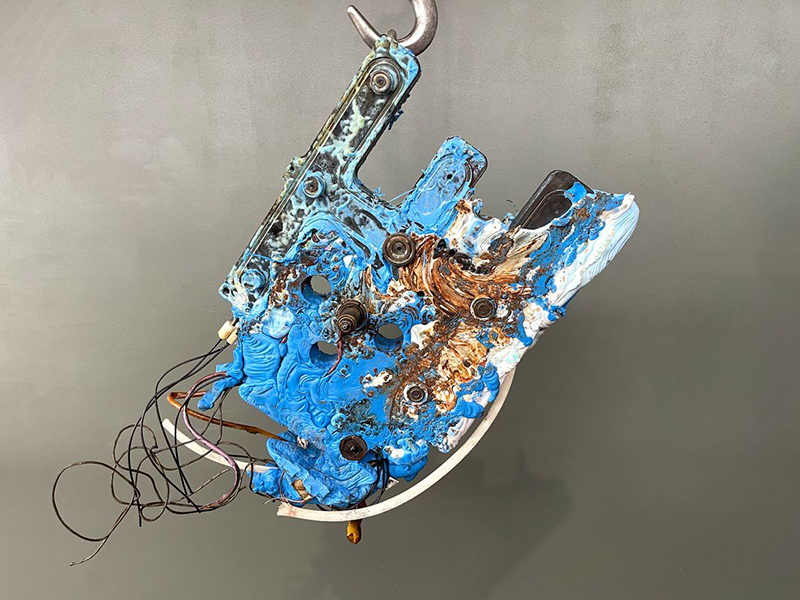

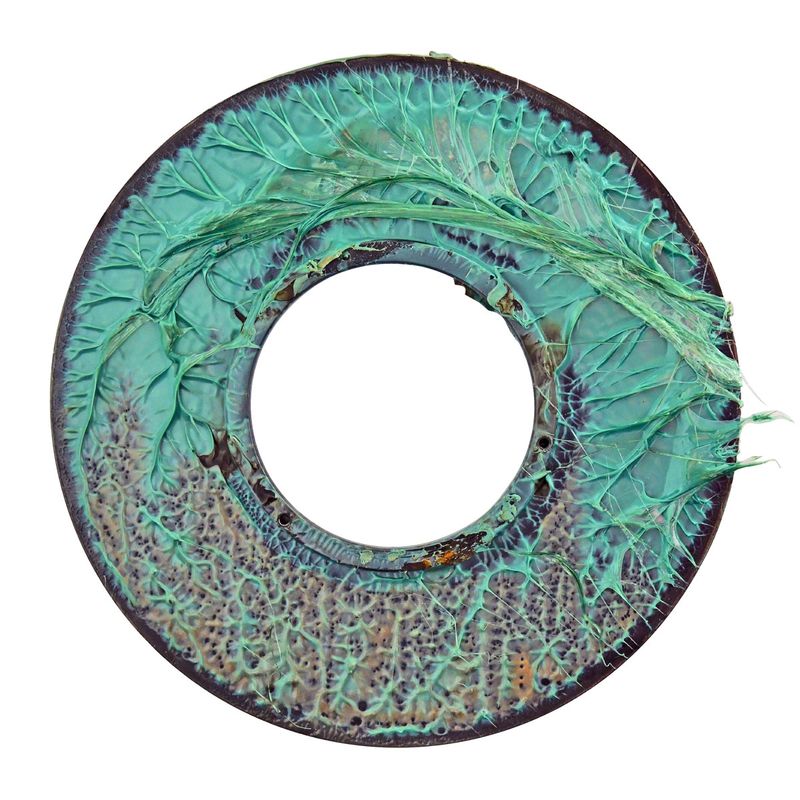

SCHWING supports film and profile manufacturers with reliable and economical cleaning solutions which facilitate the achievement of consistently perfect product quality. The systems from SCHWING clean sheet dies, die disks with filters, screen changers or extrusion screws completely from plastics of all types. Large parts such as blown film dies, screen changers or extrusion screws can also be cleaned without problems using SCHWING technologies; especially large and high-capacity systems are available for these applications.

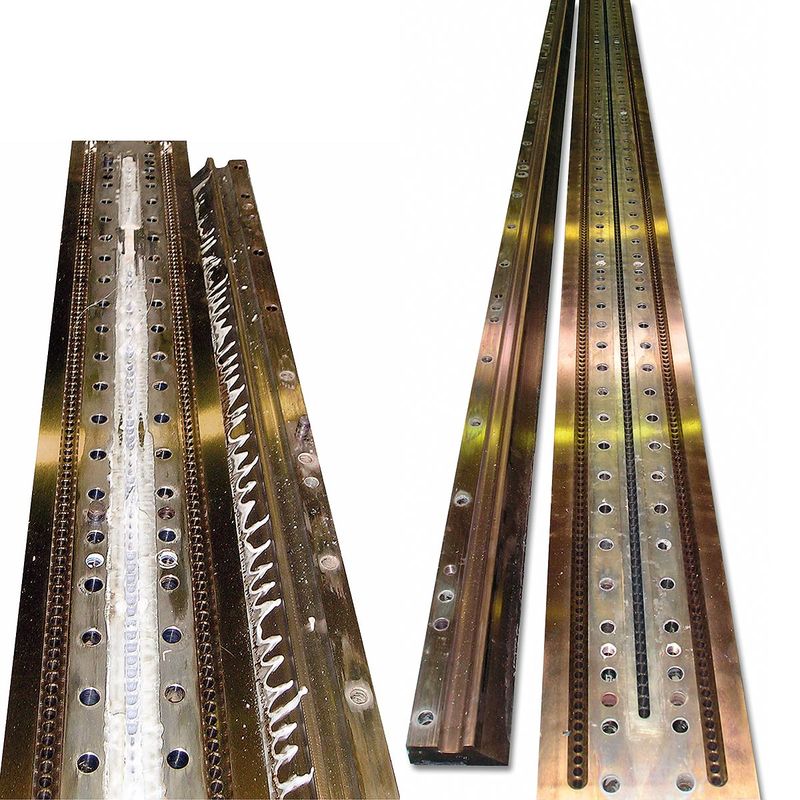

Cleaning of film extrusion dies and sheet dies

The gentle and repeatable cleaning of sheet dies and film extrusion dies is an important quality factor in film production as this ensures a long lifetime for these key production tools.

Depending on the type of the polymer and the size or geometry extrusion tools cleaning can be performed without requiring disassembly. Polymers are removed in a single step. Inorganic remnants are removed using a select after-treatment method (for example, compressed air).

The VACUCLEAN cleaning system, for example, needs eight to 30 hours – depending on the product to be cleaned – for the cleaning process at temperatures between 430 °C and 480 °C. VACUCLEAN is principally suited for all film tools including chrome-plated surfaces. The cleaning system eliminates any risk of thermal or mechanical damage to the tools.

Thermal cleaning, polymer removal

SCHWING is the only manufacturer worldwide who offers all advanced thermal cleaning technologies for the removal of all types of polymers and organic contaminations from metal tools and machine parts.

This independence from specific technologies, combined with more than 50 years of experience in the engineering of cleaning systems, uniquely enables SCHWING to handle any cleaning demand with the respective best economical and ecological equipment or system solution – including after-treatment and quality testing.

In addition, SCHWING has been offering its customers from the plastics and fiber industry cleaning services for more than 30 years. For example, at this time more than 250,000 workpieces are cleaned according to top quality and environmental standards each year at several locations worldwide and reintegrated into the production process of the customer.

Supply chain integration

The SCHWING cleaning service responds particularly flexibly to the deadline requirements and production processes of the customers. SCHWING offers extremely short processing times in three-shift seven-days-a-week operation for single, disassembled, assembled or other complex tools.

Through precise scheduling of pick-up, cleaning and delivery services SCHWING ensures, in addition, the smooth integration of the cleaning processes in the operating flow of the customer.

Products & Services

Thermal cleaning Systems

Depending on the application, product to be cleaned and polymer SCHWING offers the respective optimal thermal cleaning unit for the removal of adhering plastics and organic contaminations:

VACUCLEAN: Highly efficient vacuum pyrolysis systems for the particularly gentle cleaning of metal tools, mold and machine part

INNOVACLEAN: Fluidized bed pyrolysis systems for the particularly fast and complete removal of ALL plastics including halogenated polymers and paints

MAXICLEAN: Pyrolysis systems for the removal of polymer, plastic and paint adhesion on especially large tools and components.

COMPACTCLEAN: Compact pyrolysis devices for any plant

Contact

Schwing Technologies GmbH

Oderstrasse 7

47506 Neukirchen-Vluyn

Germany

Telephone +49 (0)2845-930-0

Fax +49 2845 930 100

Mail info(at)schwing-tech.com

Contact

Schwing Technologies GmbH

Oderstrasse 7

47506 Neukirchen-Vluyn

Germany

Telephone +49 (0)2845-930-0

Fax +49 2845 930 100

Mail info(at)schwing-tech.com