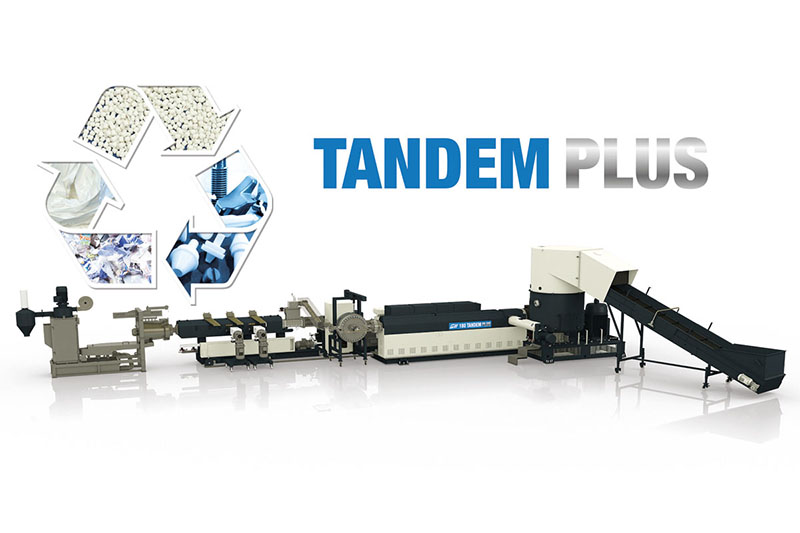

Gamma Meccanica SpA is an Italian company specialized in the design and construction of lines for the regeneration of plastic materials. Its series of GM Tandem lines is the result of constant evolution of technology characterized by higher level of automation, maximum quality of the recycled product (granules) and improved energy savings.

The Tandem line is suitable for the recycling for heavily printed, high humidity and contaminated materials

With Gamma Meccanica’s TANDEM technology it is possible to recycle heavily printed, high humidity and contaminated materials. The ultimate TANDEM PLUS line improves characteristics during the upcycling process, so it is ideal for the production of compounds from recycled materials for special applications. There are numerous advantages for customers with the possibility to obtain maximum quality of the recycled product (granules).

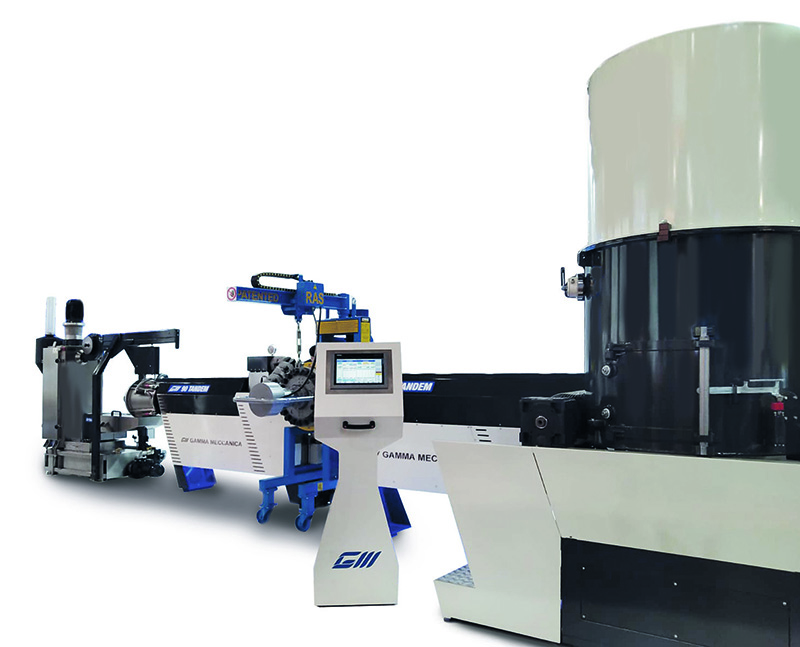

The composition of the TANDEM PLUS line

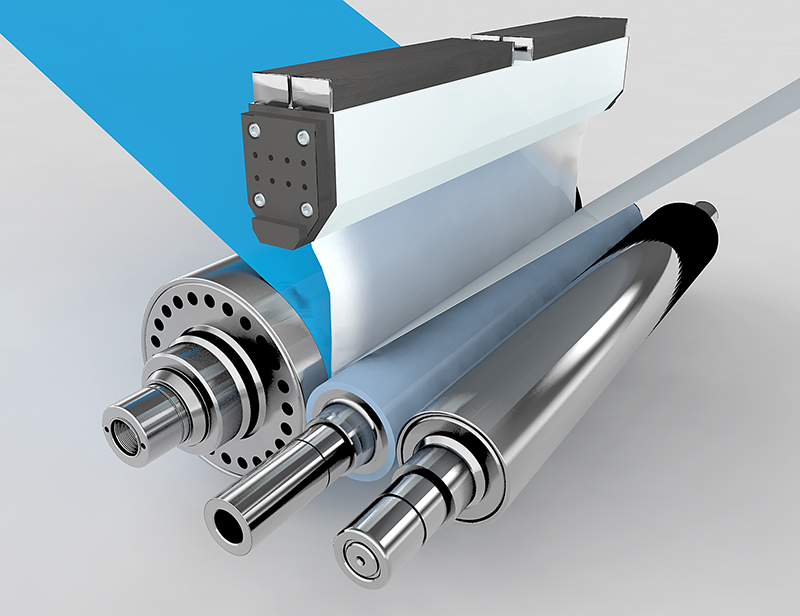

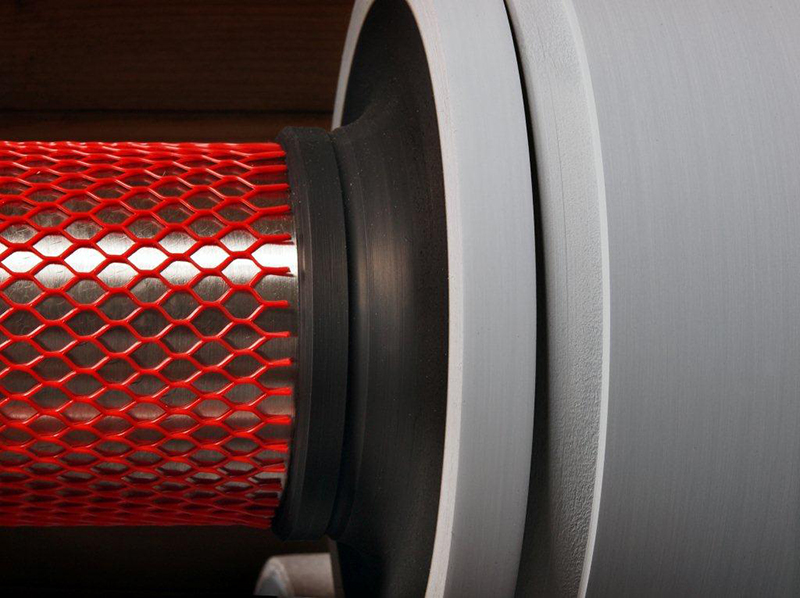

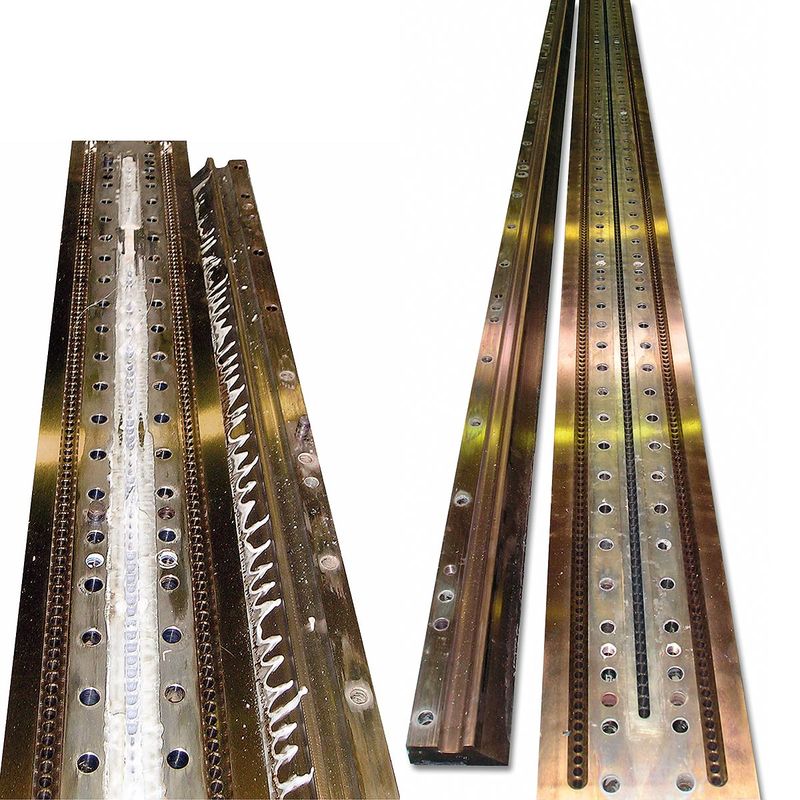

The first part of the line consists of COMPAC feeding system and a single-screw extruder. Connected to the first extruder is a self-cleaning screen changer installed to remove the contaminants present in the melted polymer. The patented Gamma Meccanica high performance vacuum system is installed at the exit of the screen changer and allows for removal of up to 10 times more gas and humidity in the melted material compared to other systems. The high performance vacuum chamber is connected to a second co-rotating twin-screw extruder. At the end of the twin-screw extruder is installed our TDA water ring pelletizer developed and produced by Gamma Meccanica.

This technological solution gives a much higher value to the product from waste with the upcycling process. Much like other solutions developed by Gamma Meccanica the TANDEM PLUS allows for contributions to the protection of the environment, both for the type of application and for better energy savings and minimum environmental impact.