High-quality film is required for encapsulation purposes.

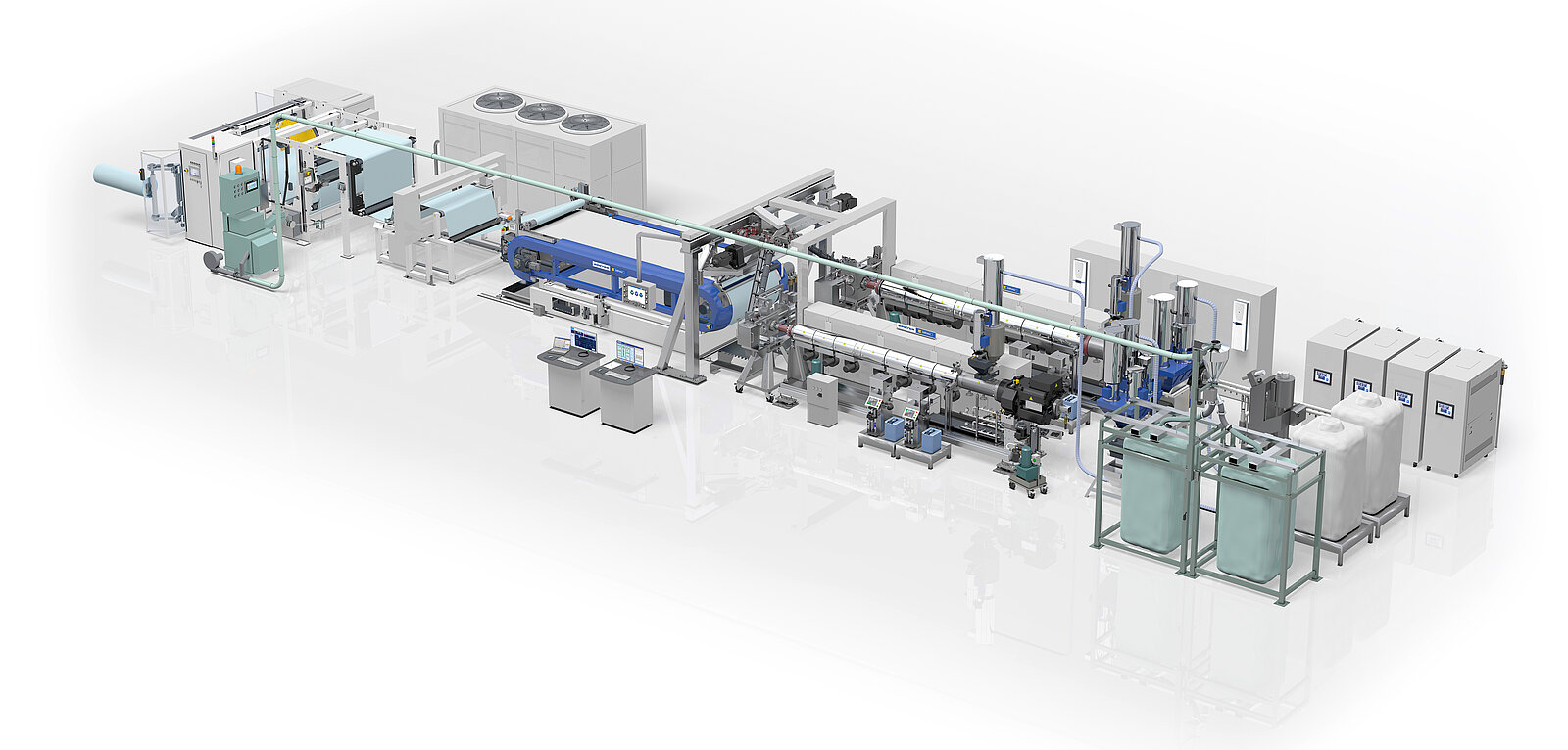

BREYER’s “CellProtect” extrusion system allows low-shrinkage EVA and POE encapsulation film to be produced at high speed.

Another benefit is that there is no energy-consuming annealing process and no interlayer film, making the production process economical and energy efficient.

Photovoltaic (PV) systems convert sunlight into electricity. Energy will continue to be a catalyst for global economic growth and prosperity, and the power of the sun lies at the heart of the renewable energy revolution. The global PV market is forecast to grow considerably in the next few years.

Consequently, the demand for encapsulant material is also growing. However, there is a physical limitation in terms of production speed. Encapsulation film produced on regular extrusion lines naturally shrinks, which affects not only the lamination process, but can also result in damaged wafers, creating waste and increasing production costs.

This shrinkage becomes particularly high if such regular lines are sped up to meet high market demand. This means that PV module producers face a higher scrap rate. Since regular extrusion systems using calenders or cast rolls are limited in terms of speed and output, BREYER supplies a profitable system for producing EVA and POE film and other adhesive materials: the CellProtect line.

High-quality, low-shrinkage film enables a smooth, fast lamination process. The greater the shrinkage of a film, the more carefully the warm-up procedure must be controlled, which could increase laminating time.

BREYER CellProtect's developed extrusion process makes it possible for the first time to extrude EVA and POE films at high speed while keeping shrinkage low. This process eliminates tension in the film from the outset.

Post-annealing systems are therefore unnecessary. This also reduces the line's energy consumption.

Producers of encapsulant film can increase their profitability by using the new technology, since the output is much higher. For module manufacturers using low-tension film, this means they can run their laminators more stably and quickly.

They will benefit from trouble-free production combined with more reliable and efficient manufacturing. Notable module manufacturers are therefore very interested in obtaining low shrinkage film.

Due to its improved properties and performance, this EVA film is set to set a completely new standard for encapsulation films and the lamination process. As well as EVA resin, other encapsulants such as POE can be processed. The benefits of POE include a water vapour transmission rate (WVTR) that is 10–20% lower, as well as non-yellowing properties and increased UV and weather resistance.

EPE processing

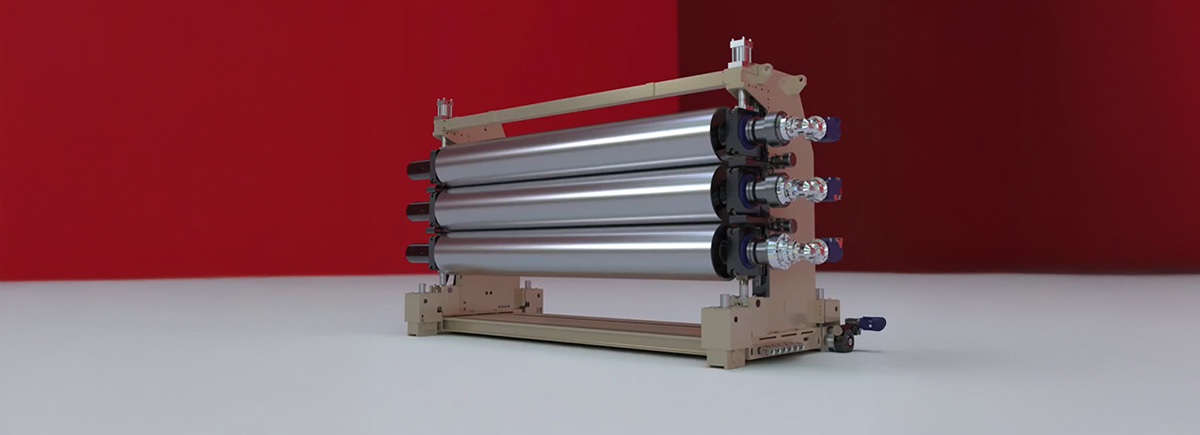

The new CellProtect machine uses multilayer extrusion to produce layered structures with EVA and POE, for example combining a middle layer of POE with two outer layers of EVA. (EVA/POE/EVA): 25/50/25. This allows the excellent adhesive properties of EVA and the good barrier properties of POE to be combined in one product.

EPE film is usually produced with a single-layer die and feed block. To improve layer distribution, Breyer can also offer a multilayer die as an alternative.

Furthermore, due to the specially designed surface of the film, a PE interlayer is no longer necessary. The rolls can be wound without PE film in between. Carrying paper, which is sometimes used in the manufacture of EVA film, is also unnecessary.

The regrind material from the edge stripes can be processed again. This saves costs and valuable resources.

The process can also be considered a 'green film production line' since it saves the interlayer and carrying paper, has no energy-consuming annealing system and features a closed-loop cooling circuit and low-temperature extrusion process.

Several different recipes, such as fast and ultrafast curing, have been successfully tested by TÜV Rheinland Germany and will be included in the BREYER TURNKEY supply.

A considerable number of systems have been sold and installed worldwide.