The Reifenhäuser Group, a leading specialist for extrusion systems and components, will be exhibiting at K 2025, the world's leading trade fair for plastics processing, in Düsseldorf from October 8 to 15. Under the motto “Boost Your Performance”, the experts will demonstrate how “Automated Extrusion”, “Smart Data” and “Innovative Training” ensure performance increases and make manufacturers less dependent on highly qualified personnel.

Marcel Perrevort, CSO of the Reifenhäuser Group, explains: "Success is closely linked to continuous improvement. However, in times of shortage of skilled workers, it is becoming a challenge for many manufacturers to achieve higher performance, better quality, greater efficiency or sustainability. We will therefore be presenting innovative technologies that give producers the extra boost they need right now. Automation, data and AI play a decisive role here."

As usual, the Reifenhäuser main booth with over 1,200 square meters will be located in hall 17, booth C 22, where the Reifenhäuser Blown Film, Cast Sheet Coating and Reicofil business units will present their line technologies for film and nonwovens applications. For the first time, the barrel and screw unit Reiloy as well as the subsidiary Kdesign - specialist for cooling, measuring and calibration technologies for blown film lines - will also be represented at the main stand. The Reifenhäuser Extrusion Systems component unit will be exhibiting in Hall 1, Stand D91. The initiative R-Cycle, co-founded by Reifenhäuser to establish an open tracing standard for plastic packaging, can be found in Hall 7 in the Start-Up Zone.

Establishing sustainability as a business model

The circular economy and CO2 reduction will also remain key topics for the entire industry at this K. Reifenhäuser will be presenting how the required recyclable products and products made from recyclate can be manufactured profitably. This is crucial for the future competitiveness of manufacturers, especially in view of the recently published PPWR (Packaging and Packaging Waste Regulation) in Europe. Marcel Perrevort says: "Producing a fully recyclable pouch is no longer the challenge. Making it profitable and competitive with conventional solutions is now the order of the day. We show technologies and film structures that enable producers to build a functioning business model around sustainability."

The Reifenhäuser Blown Film and Cast Sheet Coating units will be presenting their latest MDO (Machine Direction Orientation) technologies, which enable recyclable mono-material packaging by film stretching. Thanks to ever thinner film structures (downgauging) and clever technology features, Reifenhäuser systems reduce production costs to the same level as conventional products. Both business units focus in particular on barrier applications for the food, medical and hygiene sectors.

Operational excellence through automation, digitalization and training

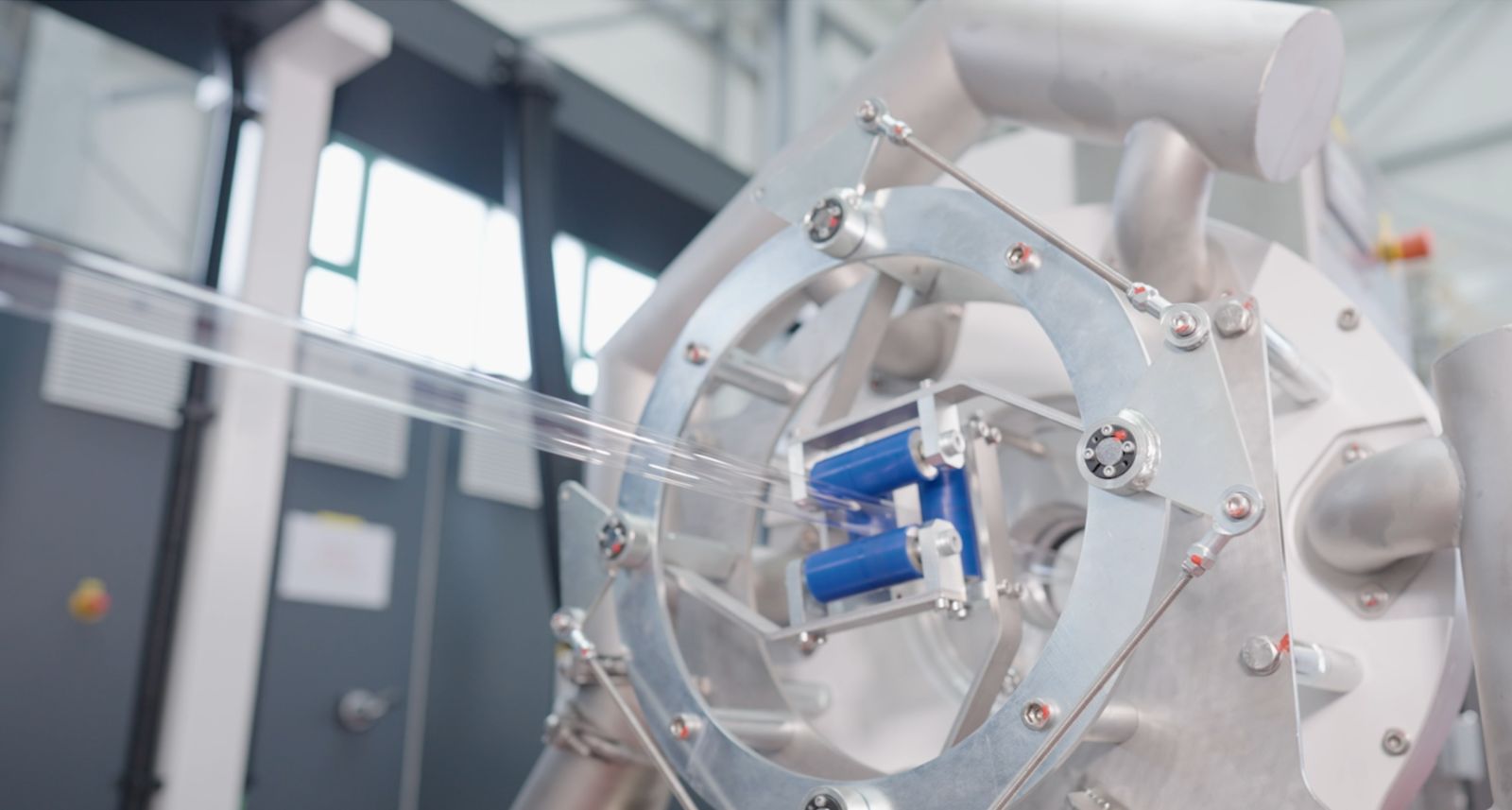

In day-to-day production, plastics processors are often dependent on highly qualified personnel in order to exploit the full operational potential of their extrusion systems. The need for automation is therefore constantly growing. At K, Reifenhäuser is launching new developments in this area and presenting further developments of already proven automation options - above all the patented PAM system (precise, autonomous, mechatronic) for flat film lines. The automation option uses mechatronic actuators to automatically control the coextrusion adapter and die during operation. The second generation of this system, which is unique on the market, will be presented for the first time at K.

Digital solutions are another decisive factor for operational excellence. Reifenhäuser offers powerful software tools for connecting machines, data analysis and automatic process monitoring and optimization of production. In addition, Reifenhäuser provides scalable learning opportunities - for more effective training and the best possible qualification of production employees. In order to further expand its commitment to the digitalization of the plastics industry, the Reifenhäuser Group will bundle its digital and learning solutions under the Reifenhäuser NEXT brand in the future. The new business unit will focus on the seamless integration of Industrial AI and will present its new product portfolio for the first time at K.

For the exchange of packaging data across companies, Reifenhäuser is driving forward the open tracing standard R-Cycle. Producers can use it to efficiently digitize their packaging data management in order to meet the growing information requirements of the PPWR. R-Cycle can be used immediately as a software-as-a-service solution and is supported by a community of over 30 globally active companies.

"At K 2025, we will be showcasing an enormous range of innovations around our extrusion technologies and setting new performance and profitability benchmarks in the market. We will also be offering unique automation features as well as digital solutions as part of our Reifenhäuser NEXT brand launch. The K show will be the ideal stage for discussing specific applications with our customers and demonstrating concrete added value," explains Marcel Perrevort.

About the Reifenhäuser Group

The Reifenhäuser Group together with its highly specialized business units is the leading provider of innovative technologies and components for plastics extrusion. Founded in 1911, the company is a global supplier of high-tech solutions. With its technologies and the know-how of its 1,500 employees, Reifenhäuser has the world's largest network of expertise in plastics extrusion technologies. The CEO of the Group is Bernd Reifenhäuser.