CUSTOM ENGINEERING FOR A CHANGING WORLD

Macro Engineering & Technology Inc. has established itself as a leader in the global extrusion sector, offering state-of-the-art technology and its patented Quadex™ film lines, which range from monolayer to multilayer options and various shrink capabilities. Macro has sold Quadex™ lines across the world. Macro has a 7-layer, Quadex™-3B line in its lab which is the first of its kind in North America. This newly installed lab line can assist clients in transitioning away from PVDC for shrink and non-shrink film applications. “We’ve received inquiries from producers uncertain about the future of PVDC or whether the shrink market will shift to EVOH for certain products,” explained Dr. Karen Xiao, VP of Technology at Macro. “We’ve already developed lines capable of running both PVDC and EVOH”.

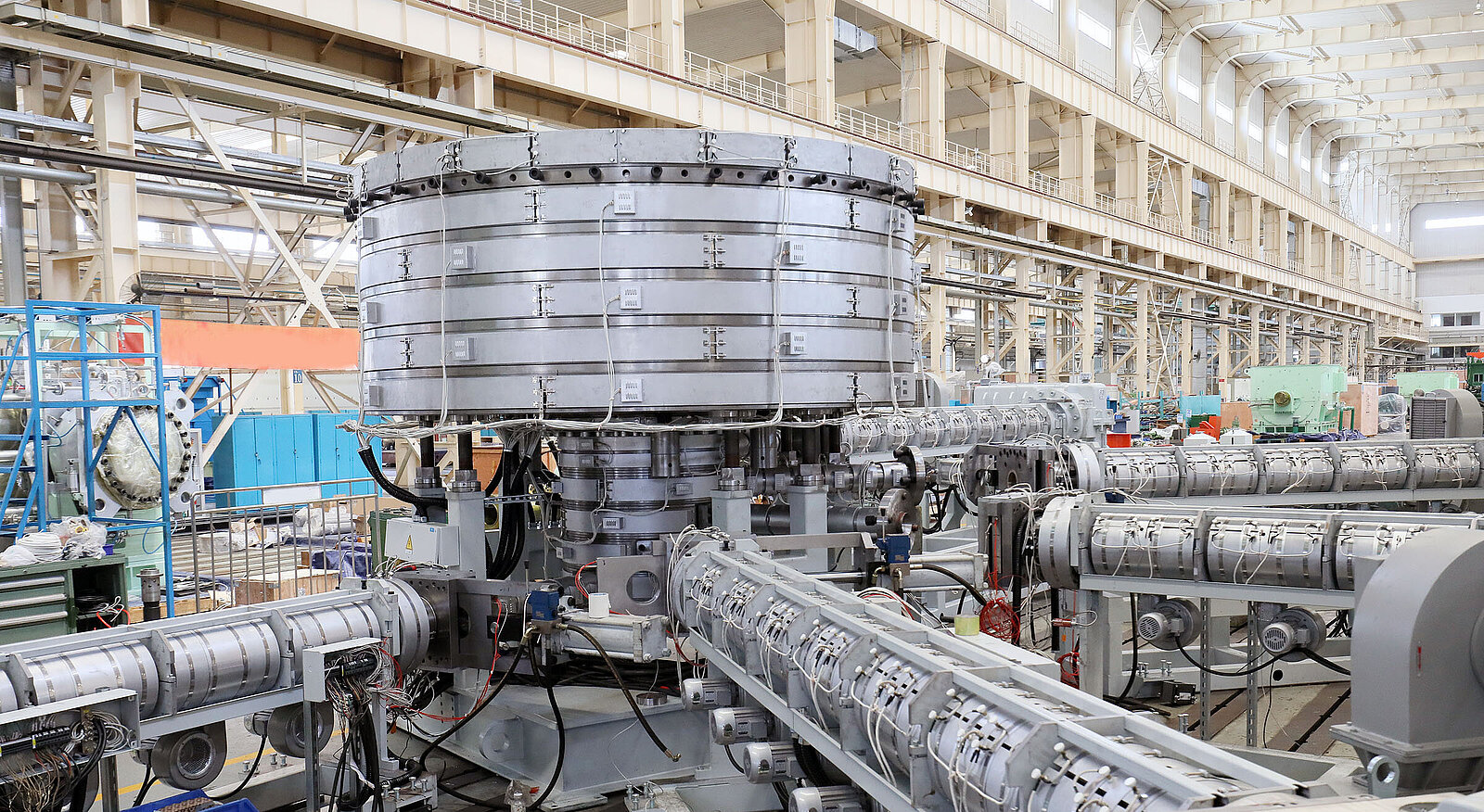

Macro’s Quadex-2B & 3B Series of coextrusion Biax (biaxially-oriented) film lines produce high performance multilayer barrier films for food packaging applications, such as meat, cheese, and poultry packaging for shrink films and shrink bags.

Macro’s Quadex™ line efficiently performs the four basic processes for producing bixially oriented films: Extrusion, Quenching/Re-heating, Orientation, and Annealing. “Our Quadex™ line is designed for efficiency and quality, using the latest proprietary technologies and state-of-the-art components” explained Dr. Xiao.

Key Features of Quadex™ Line:

Versatile extrusion technology can produce films with a variety of resins (EVOH, PVDC, PA, Ionomer, EVA, PE).

Advanced quenching and re-heating systems are available to achieve the specific film properties for different applications.

Stable orientation process that allows for long production runs without bubble break.

Versatile annealing station allows for controllable film shrink properties.

CUSTOM WINDERS

Aside from the technologies available on winding equipment that come standard on Macro’s extrusion systems, Macro provides comprehensive winding solutions for a wide range of materials and automation requirements. Over the past 47 years, Macro has built a worldwide reputation as a designer of sophisticated winding machinery. Hundreds of custom designed winders have been manufactured by Macro for a wide variety of materials including:

Flexible films

Extensible and tacky films

Stretch wrap films

Embossed films

Bubble wrap

Sheet of varying thickness and rigidity

Roofing material

Shallow thermoformed sheet

Corrugated sheet

With a focus on innovation, precision, and automation, Macro Engineering & Technology Inc. continues to lead the way in winding technology. Whether you need high-speed performance, specialized configurations, or a fully customized system, Macro delivers reliable, high-performing solutions designed for today’s competitive market.

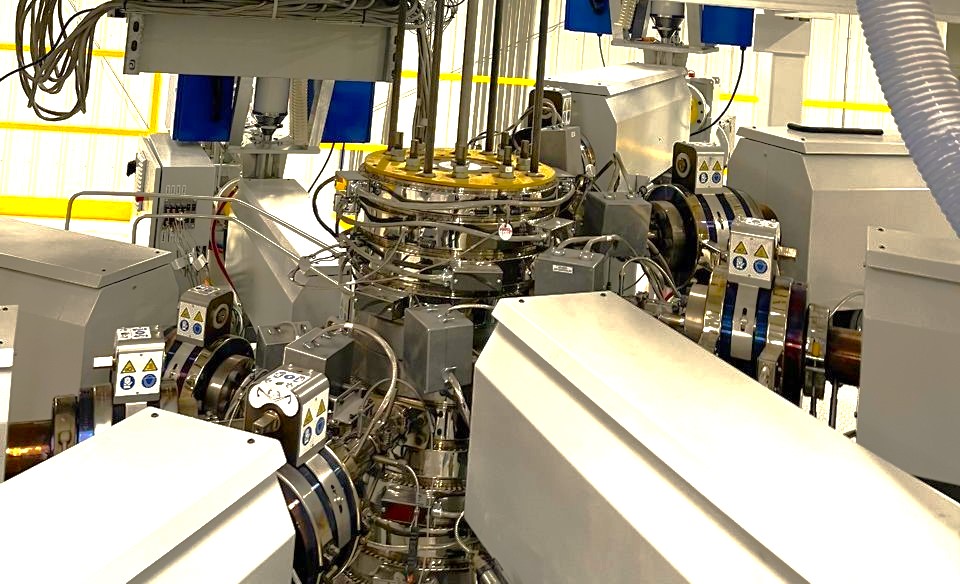

MACROPACK COEXTRUSION BLOWN FILM DIES

Macro has obtained multiple blown film die patents for the processing of multilayer films and the co-extrusion of sensitive plastic materials with encapsulation. Dozens of blown film dies varying from specialty single layer uses to complex coextrusion applications are manufactured by Macro every year.

We recognize that different market demands and applications make it difficult for one die type to be effective across all sizes and extrusion applications. To address this issue, Macro has tailored its die designs into different categories.

For more information, please contact: Martin Baron, Director of Sales: mbaron@macroeng.com, or +1 (905) 507-9000.