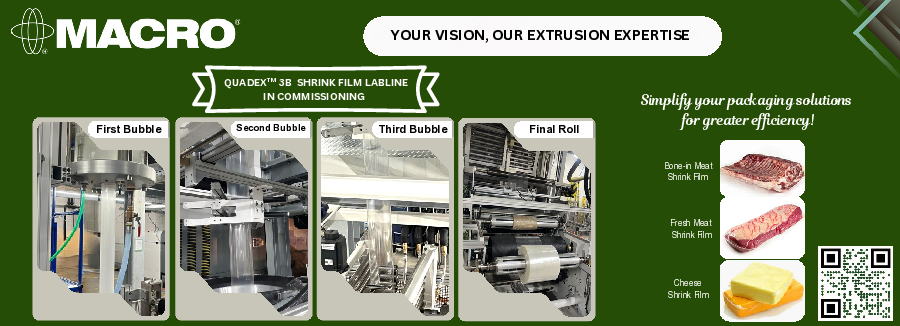

Macro’s patented Quadex™ line technology is the ideal solution for processors seeking to produce high performance multilayer barrier films for food packaging applications, such as meat, cheese, and poultry packaging films, shrink bags, and casings.

Macro’s Quadex™ line efficiently performs the four basic processes of producing biaxially oriented (Biax) films: Extrusion, Quenching/Re-heating, Orientation, and Annealing. “Our Quadex™ line is designed for efficiency and quality, using the latest proprietary technologies and state-of-the-art components” explained Dr. Karen Xiao, VP of Technology at Macro.

KEY FEATURES OF MACRO’S QUADEX™ LABLINE:

• 7-layer film structure,

• Final film layflat ranges from (180-500) mm,

• Equipped with a die with multiple lipsets ranging from (60-150) mm,

• Versatile annealing station for controlling film shrink properties,

• Production of heat-shrinkable films with PA, EVOH and mono-material structures,

• Accommodates a range of barrier and non-barrier film development structures.

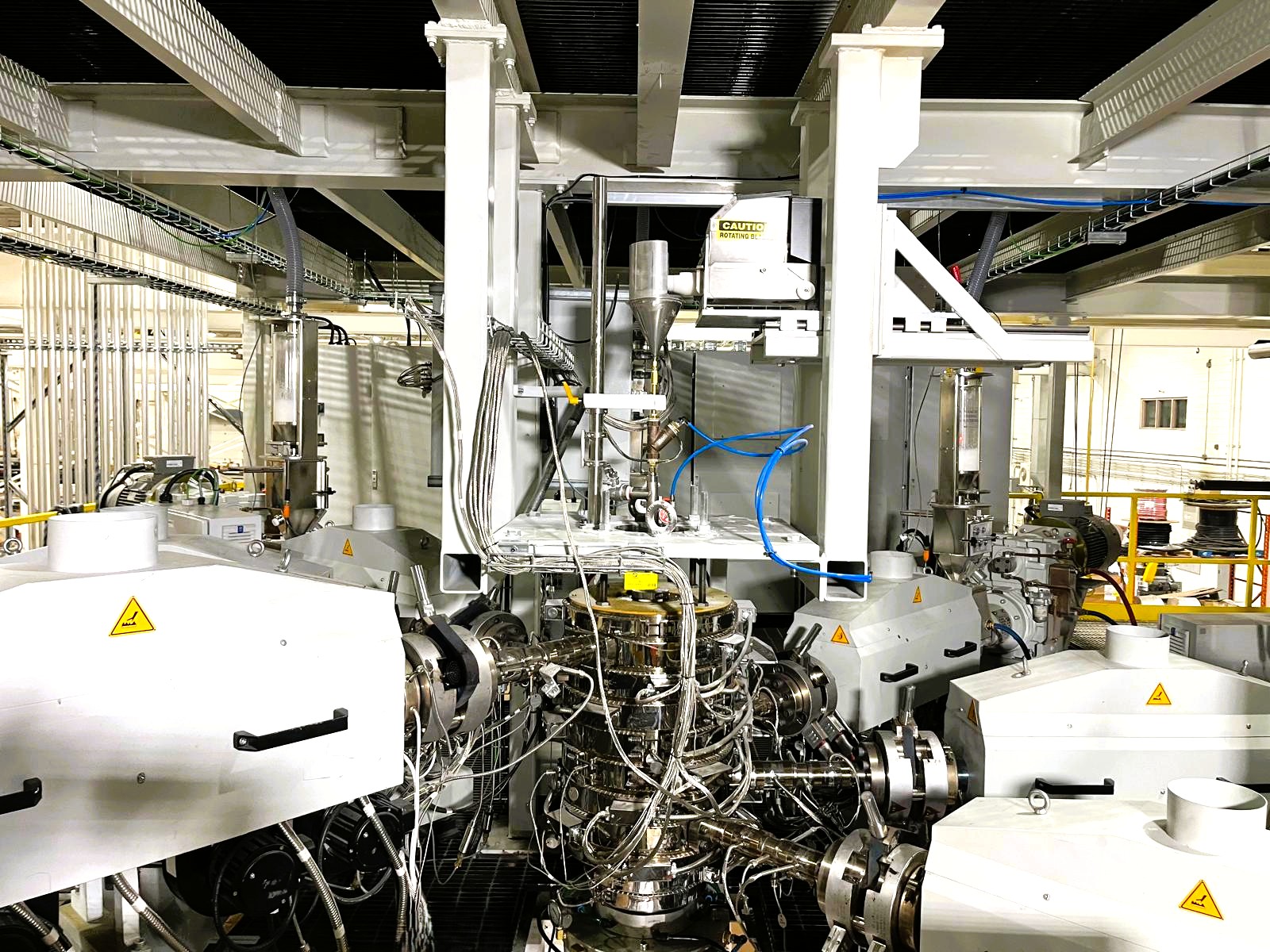

Using Macro's advanced coextrusion technology, thanks to our MacroPack-FP™ die, along with professionally designed extrusion screws, Macro’s Quadex™ labline allows the processor to extrude a wide variety of polymers from EVOH, Nylon (PA) and mono-material structures; allowing the flexibility to adapt the product to the market needs.

The water-quenching system along with an advanced vacuum calibrator unit ensure that the primary tube is precisely calibrated for the size needed. “Operation of the vacuum calibrator and water quenching system is simple and allows for adjustments to be made in a short period of time, generating cost savings by reducing scrap during production changeover” explained Dr. Hassan Eslami, Extrusion and R&D manager at Macro.

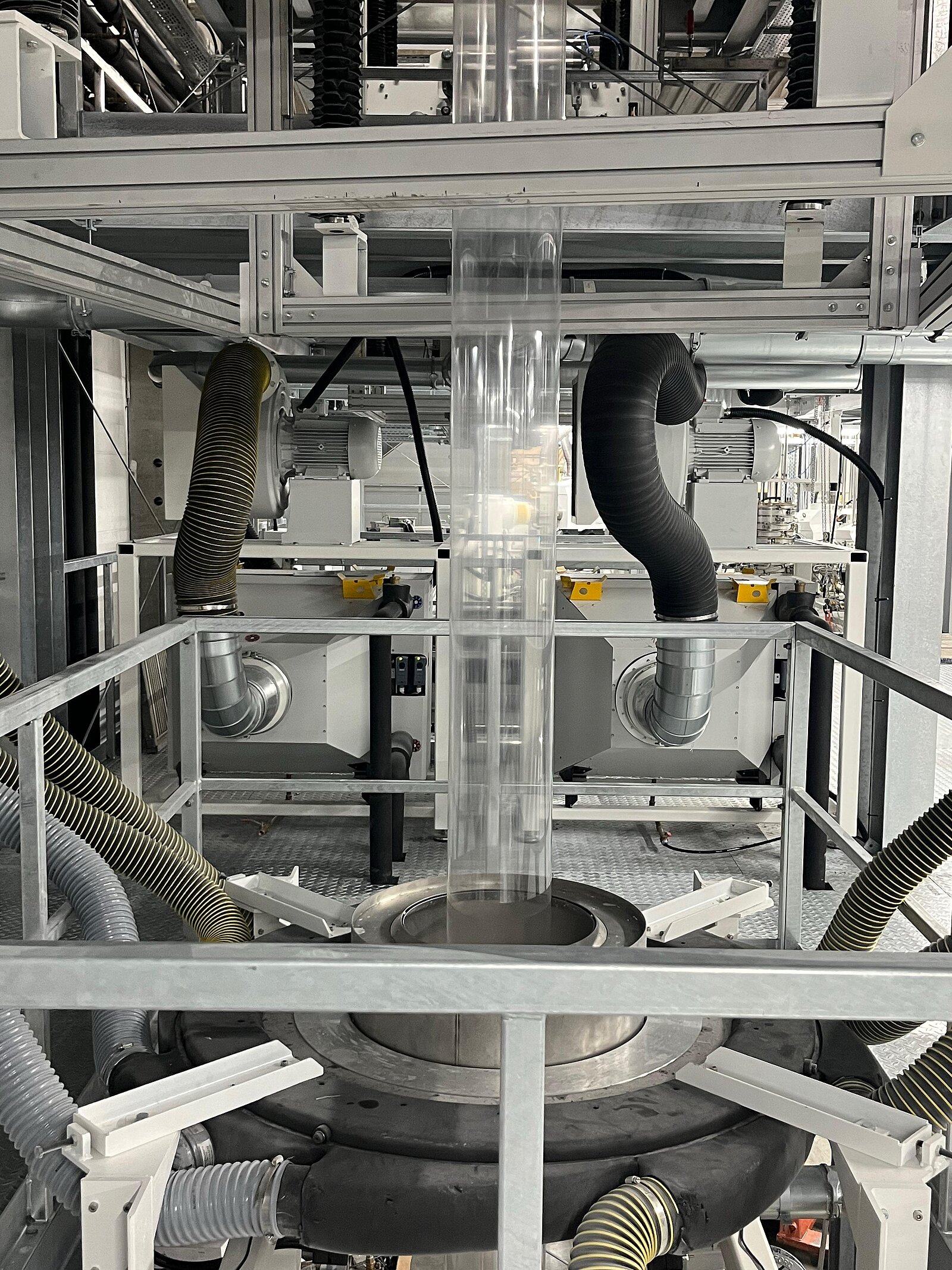

Macro's proprietary re-heating technology ensures the temperature uniformity of the primary tube, allowing a precise and controllable MD/TD orientation process during bubble re-blow.

The orientation unit is stable, thanks to our novel auto profile control (APC) air ring design, guaranteed gauge uniformity, fast start-up and long run without bubble break. This will also allow the processor to control the shrink properties of the final film.

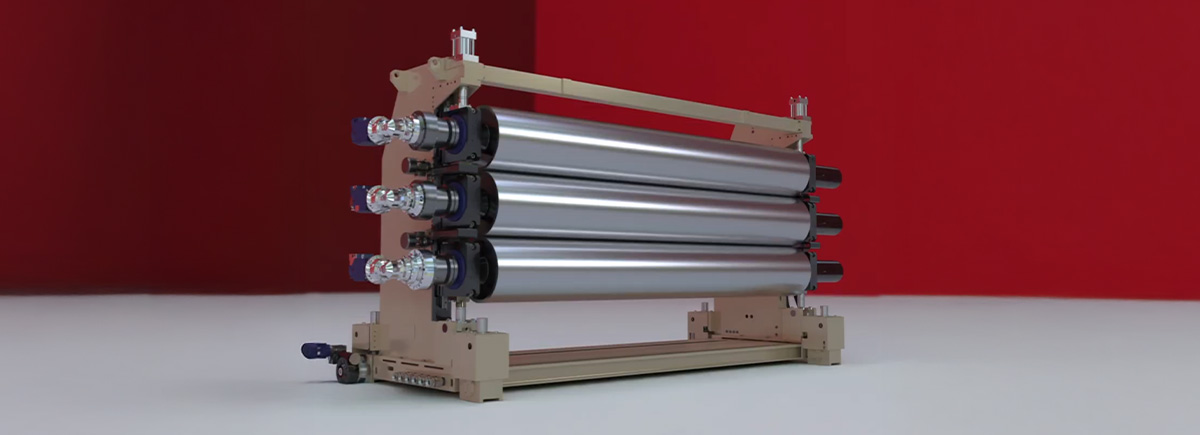

Our versatile annealing station can be chosen based on customer’s space availability and desired final films shrink properties. The versatile design facilitates to control final film shrink properties and film flatness.

The line is equipped with a gauge randomizing unit to ensure high quality roll production. Final roll creation is performed by Macro's advanced surface winder, which features programmable tension tapering and fully automatic cutovers.

About Macro

Macro Engineering & Technology is a global supplier of film and sheet extrusion systems that specializes in barrier film lines and custom engineered extrusion systems. Founded in 1978, Macro’s approach is to help film and sheet producers reach their production goals through a project-oriented philosophy and an uncompromising commitment to developing innovative technologies.

Macro manufactures blown, cast and QuadexTM biaxially oriented coextrusion lines for multilayer films up to 13-layers. The company also supplies sheet extrusion lines for specialty applications, along with coextrusion dies, air rings and winding solutions to meet the needs of complex requirements.

Macro’s equipment is used throughout the world to manufacture value-added products in the food packaging, medical, and industrial markets.

For more information, please contact:

Martin Baron, Director of Sales: mbaron@macroeng.com, or +1 905 507 9000.