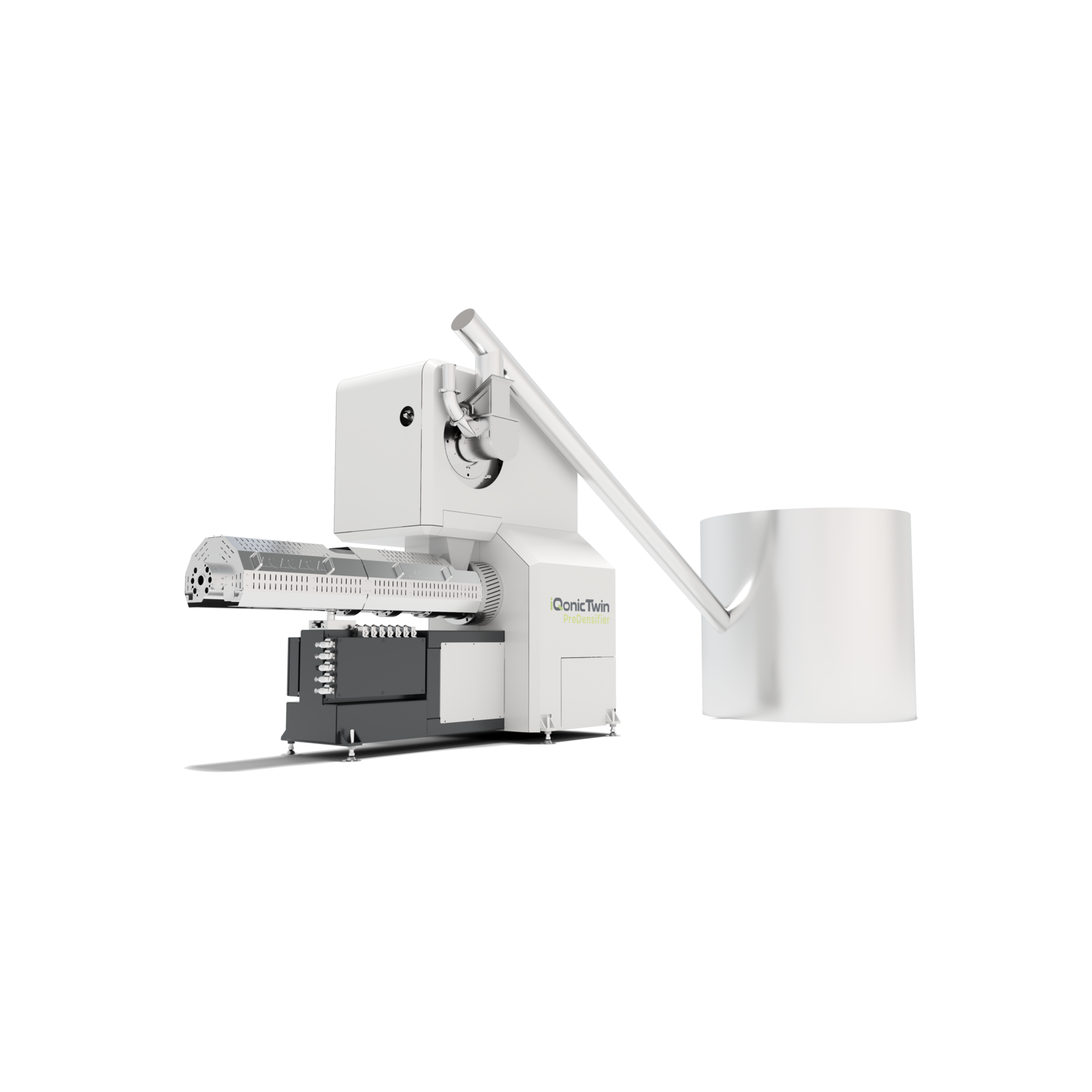

Technology alliance between MAS and Siempelkamp Size Reduction (formerly Pallmann) unveils advanced film and lightweight materials recycling solution: The “iQonicTwin PreDensifier”

In a strategic technology alliance, MAS and Siempelkamp Size Reduction (formerly Pallmann) have combined their expertise to develop a next-generation solution for the most demanding film recycling applications: the “iQonicTwin PreDensifier”.

Post-consumer film recycling becomes increasingly vital, especially in the packaging industry. The challenge of processing lightweight, fluffy films with air pockets, inks, and adhesive layers persists. These materials are notoriously difficult to handle and often lead to inconsistent quality and energy inefficiencies.

While the conventional cutter compactor route was considered, MAS and Siempelkamp Size Reduction (formerly Pallmann) chose to aim higher – pursuing unmatched performance and quality.

Cutter compactors can no longer meet the growing demand for top quality, as their process control cannot ensure a uniform melting process, leading to quality fluctuations in the extruder feed.

“The iQonicTwin PreDensifier represents the fusion of two proven top technologies and marks a significant leap forward in recycling process stability, efficiency, and product quality.”

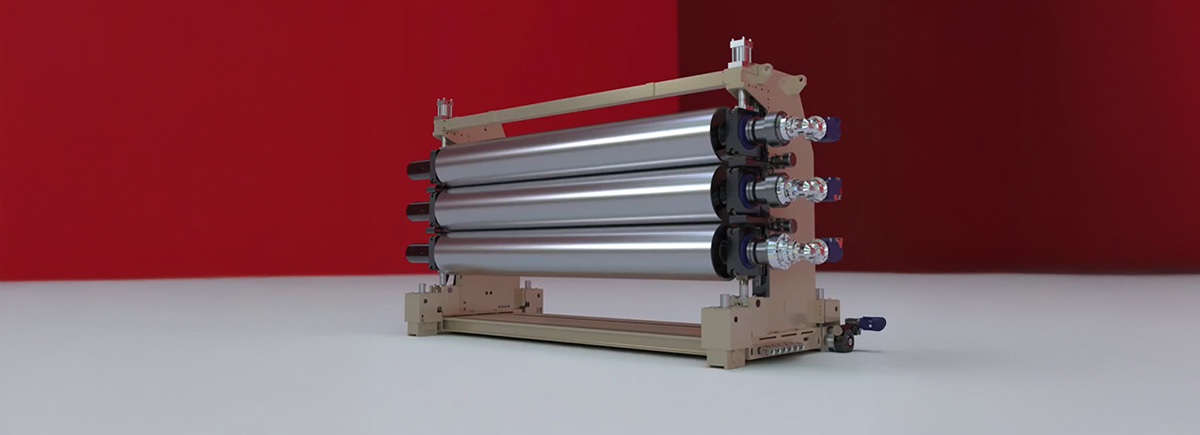

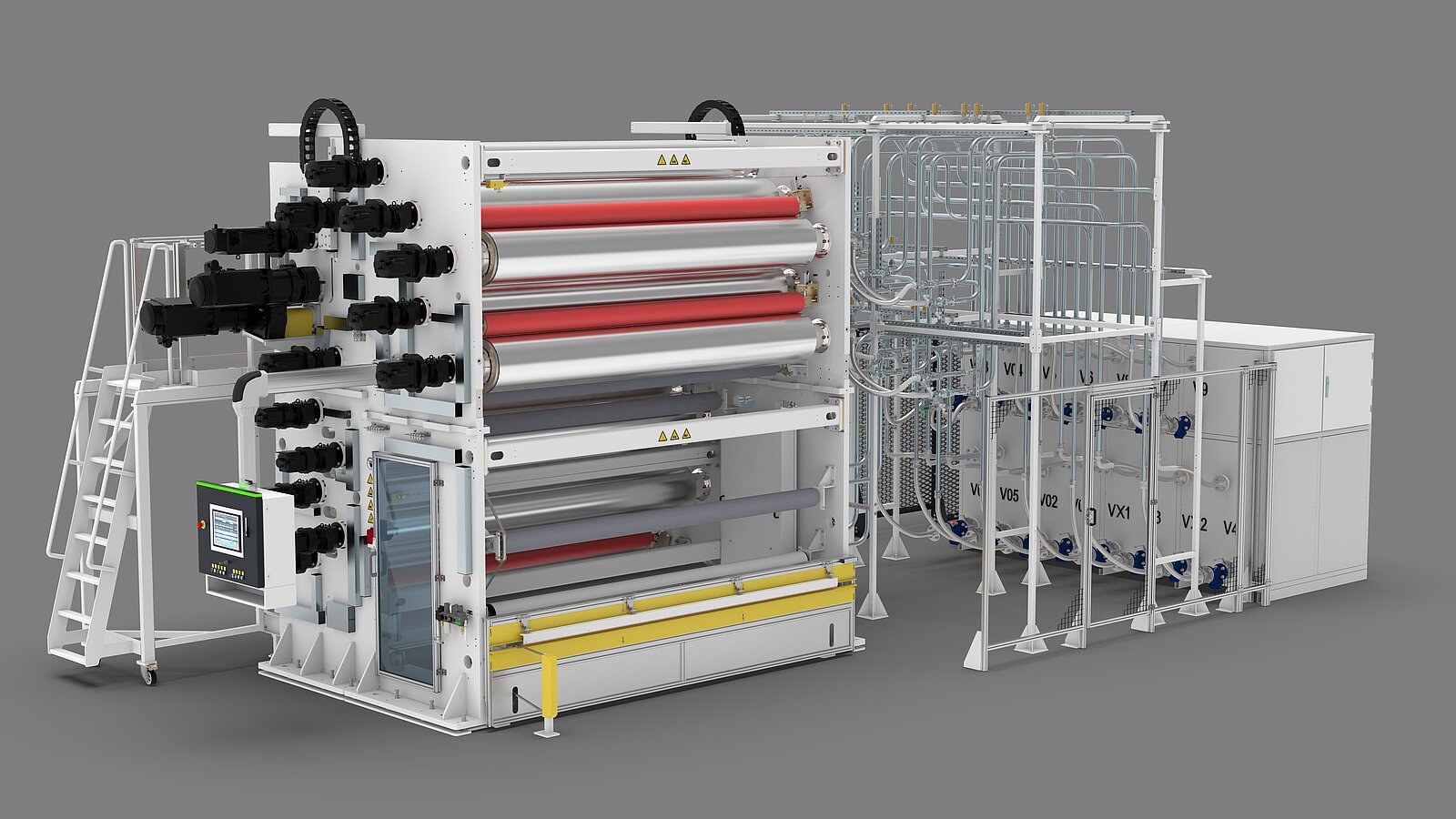

The machine combines PALLMANN’s high-performance PreDensifier with MAS’s energy-efficient conical co-rotating twin-screw extruder - delivering an exceptional set of technical and economic benefits.

Key benefits of the iQonicTwin PreDensifier:

- Significantly reduced gel formation & black spots - Low energy input, less mechanical stress

- Stable, reliable and reproducible processing - even with fluctuating feedstocks - Consistent material quality

- High energy efficiency

- No dust emission, no water injection

- Compact design and simplified maintenance - Seamless integration into existing systems

- Instant start/stop capability incl. no warm-up needed

- Easy cleaning, faster material change

- Full process control (start/stop, emergency stop, monitoring)

- No cake formation as seen with cutter compactors

- Ultra-automated

From films and fibers to PP ropes, nonwoven materials, fleece, and even XPS recycling, the iQonicTwin PreDensifier delivers consistent, high-quality results across a wide range of applications, setting new benchmarks in recycling performance.

The iQonicTwin PreDensifier is now available and will be officially launched at the K show in Düsseldorf from October 8 – 15 at booth MAS@D30 and PALLMANN@A10.