Flat roof waterproofing membranes are one of the most dynamic segments in the global construction materials market. Increasing urban density, refurbishment of ageing buildings and stricter energy-efficiency requirements are driving demand for high-performance roofing systems. According to market sources, the global waterproofing membranes market surpassed USD 30 billion in 2024 and is projected to approach USD 48 billion by 2032, with TPO roofing membranes showing an annual growth rate close to 6%.

Among available technologies, TPO (Thermoplastic Polyolefin) membranes are widely recognised as the most advanced solution for modern flat roofs. By combining elastomeric compounds with polypropylene, TPO membranes offer excellent weather resistance, flexibility at low temperatures, UV stability and long service life, typically exceeding 25 years. In addition, their chlorine-free composition and recyclability align with current sustainability goals in the construction sector.

Multilayer structures require advanced processing

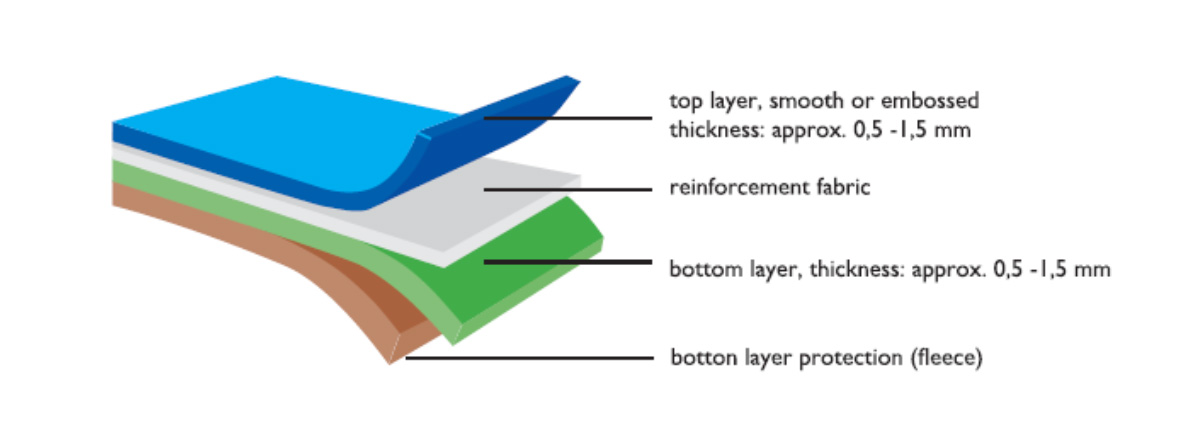

Contemporary TPO membranes are engineered as multilayer systems, where each layer performs a specific function: mechanical strength, dimensional stability, UV protection, vapour permeability or surface performance. Reinforcement layers in nonwoven fabrics or meshes further enhance tensile strength and durability, especially in industrial and commercial roofing applications.

Producing these complex structures requires sophisticated extrusion and calendering technologies, capable of maintaining tight tolerances over large widths while guaranteeing consistent bonding between layers.

BG Plast extrusion technology for TPO roofing membranes

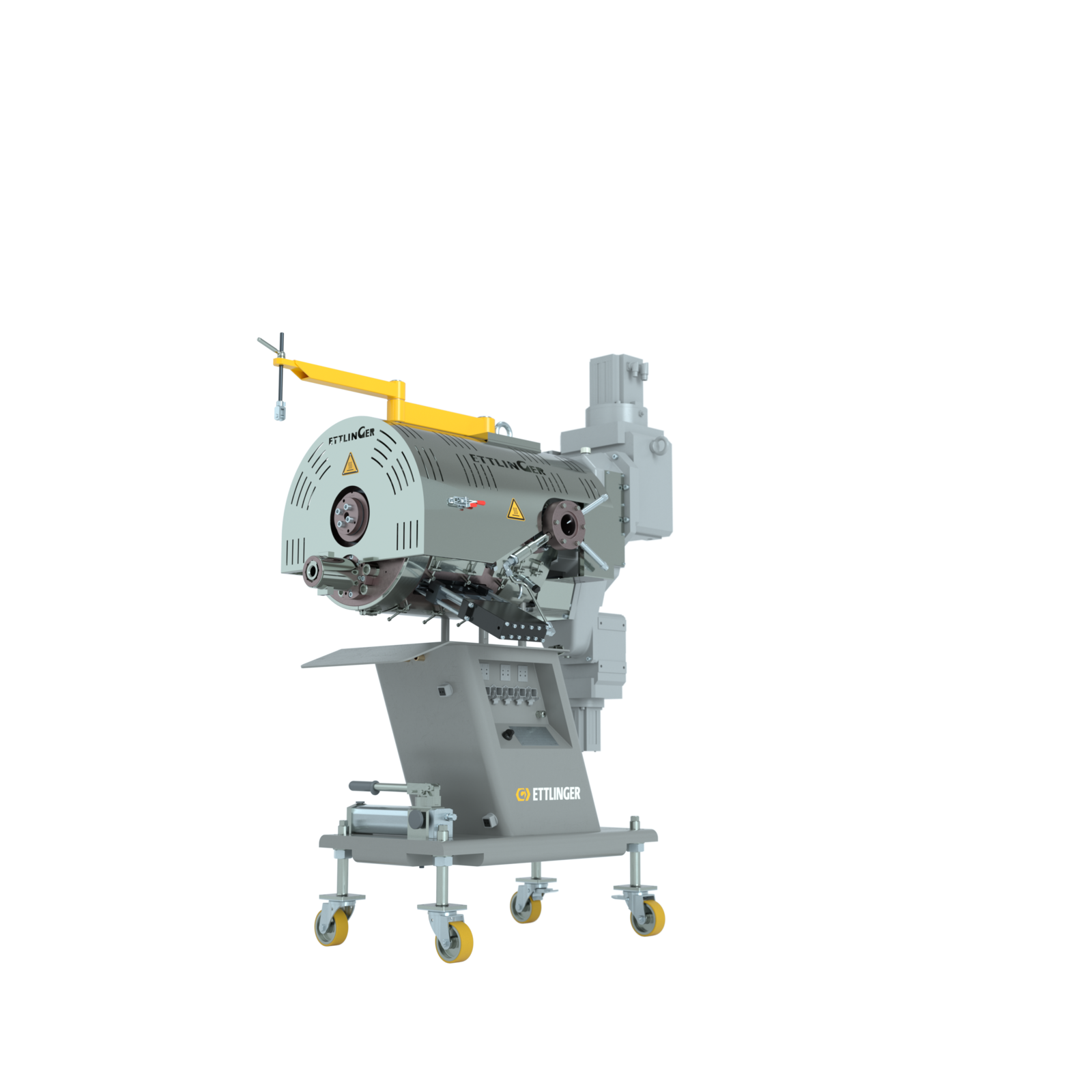

With nearly four decades of experience in extrusion and calendering, BG Plast designs and manufactures complete production lines dedicated to TPO waterproofing membranes, covering the entire process from raw material preparation to final winding. Depending on formulation complexity, throughput targets and multilayer architecture, the company integrates single-screw extruders for stable, homogeneous compounds, as well as counter-rotating or co-rotating twin-screw extruders where intensive mixing and accurate control of additives are required.

The calendering section is the real core of the process. BG Plast supplies three- or four-roll calenders in horizontal, diagonal or vertical configurations, equipped with independent roll temperature control and accurate gap adjustment to ensure uniform thickness and surface quality across the full membrane width. Thermal lamination and coating technologies allow the in-line integration of reinforcements and functional layers, resulting in highly consistent multilayer structures produced within a single, controlled process.

Concrete advantages for manufacturers

BG Plast lines are designed to maximize production flexibility, enabling quick transitions between different membrane types, thicknesses and formats. High process stability provides consistent quality, while energy-efficient designs reduce operational costs and waste. Compatibility with recycled materials supports circular economy strategies, increasingly demanded by the roofing market.

Thanks to tailored engineering, modular layouts and long-term technical support, BG Plast positions itself as a strategic partner for manufacturers seeking reliable, scalable and future-proof solutions for TPO roofing membranes.