BG Plast expands in extrusion coating.

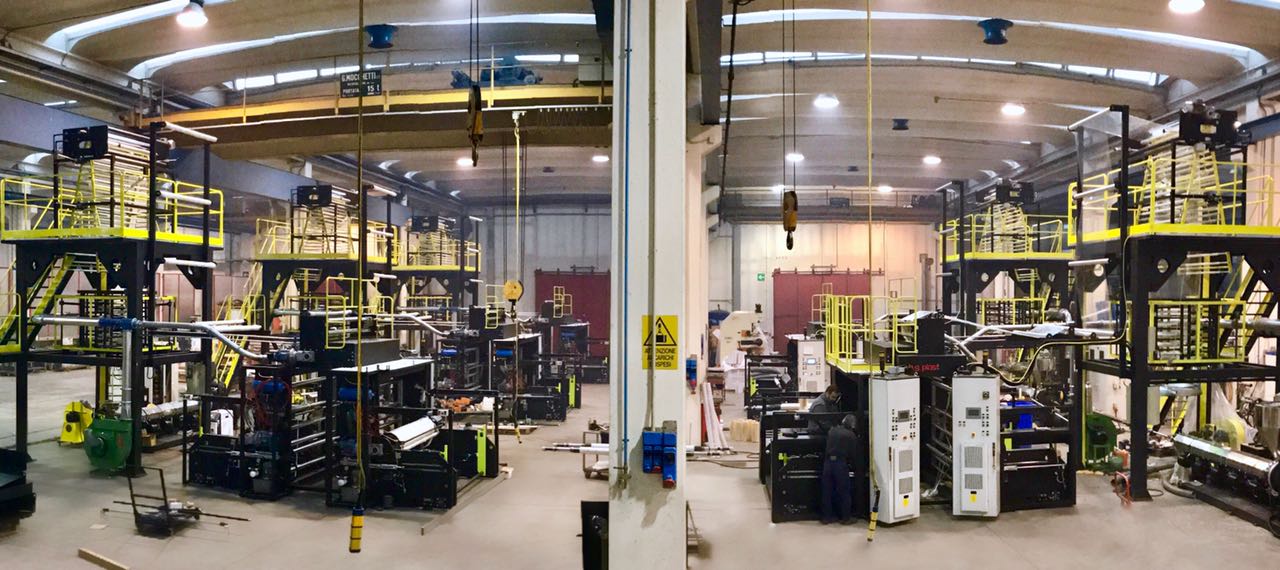

With over three decades of experience in extrusion plant engineering, BG Plast continues to reinforce its position in the thermoplastics processing industry. Headquartered north of Milan, Italy, the company specializes in the design and manufacturing of extrusion and calendering lines for films, sheets, and technical coatings. Its solutions are widely adopted in sectors ranging from automotive to construction, footwear, and packaging.

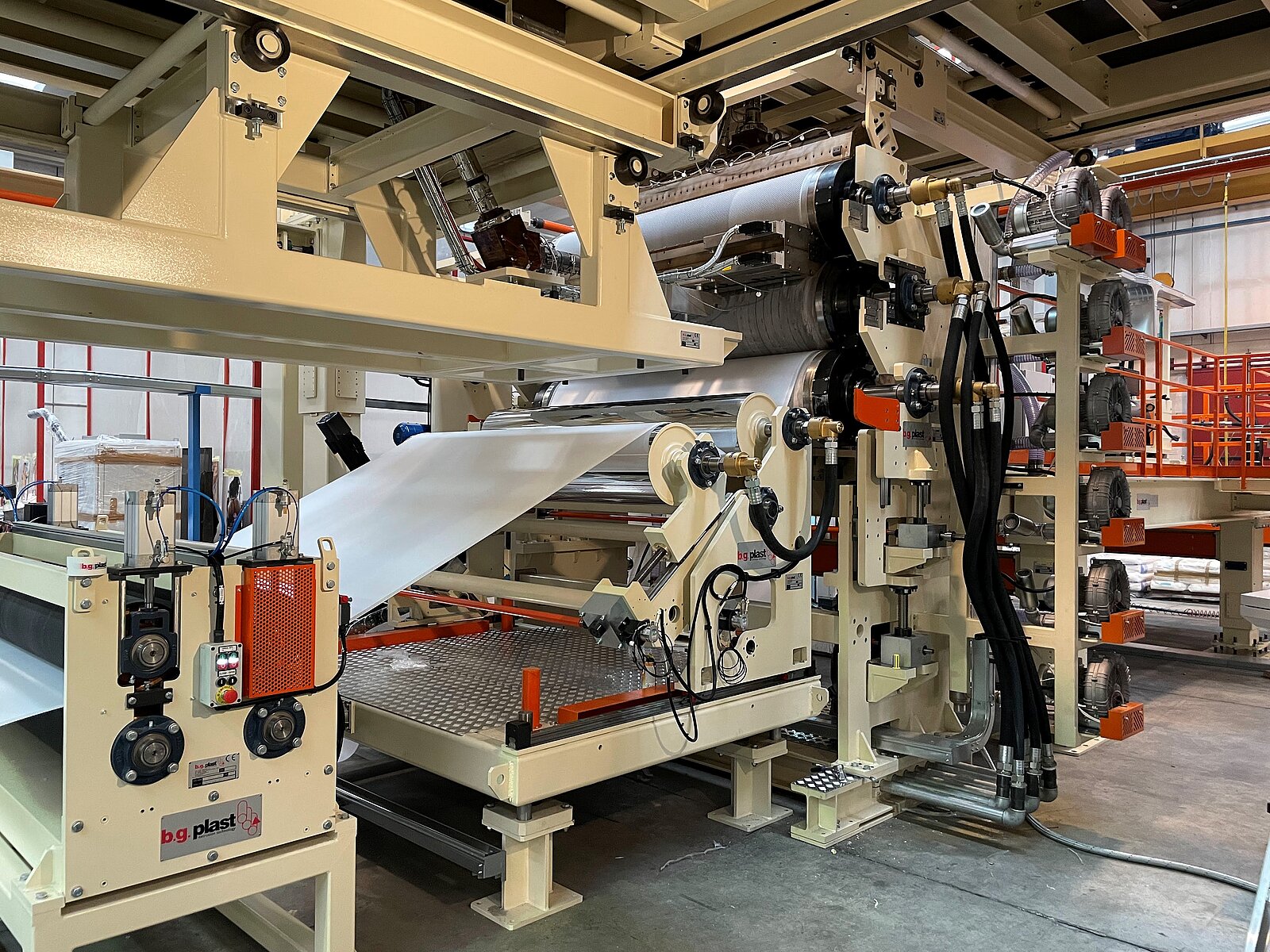

New high-capacity extrusion coating line installed in Poland

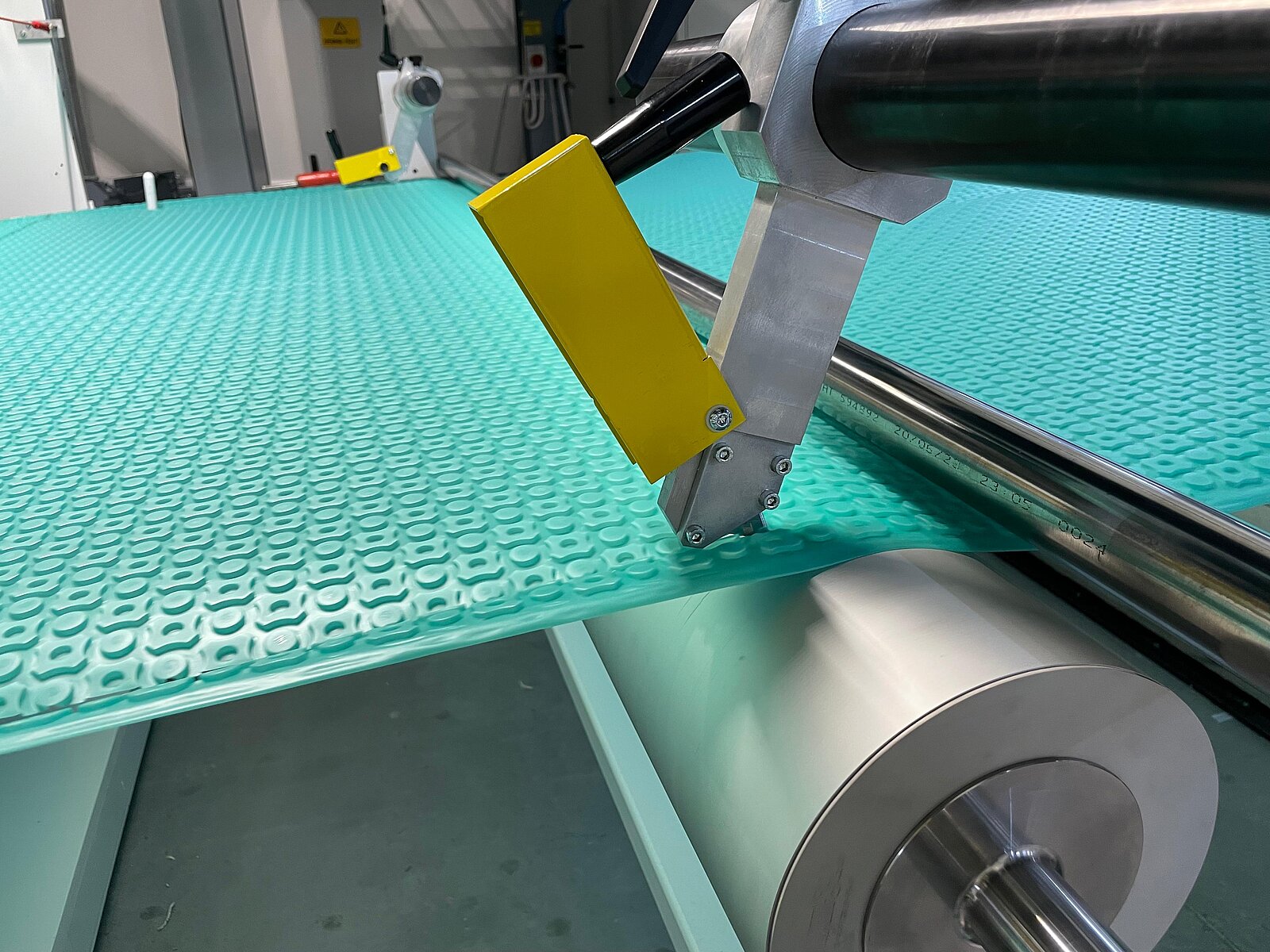

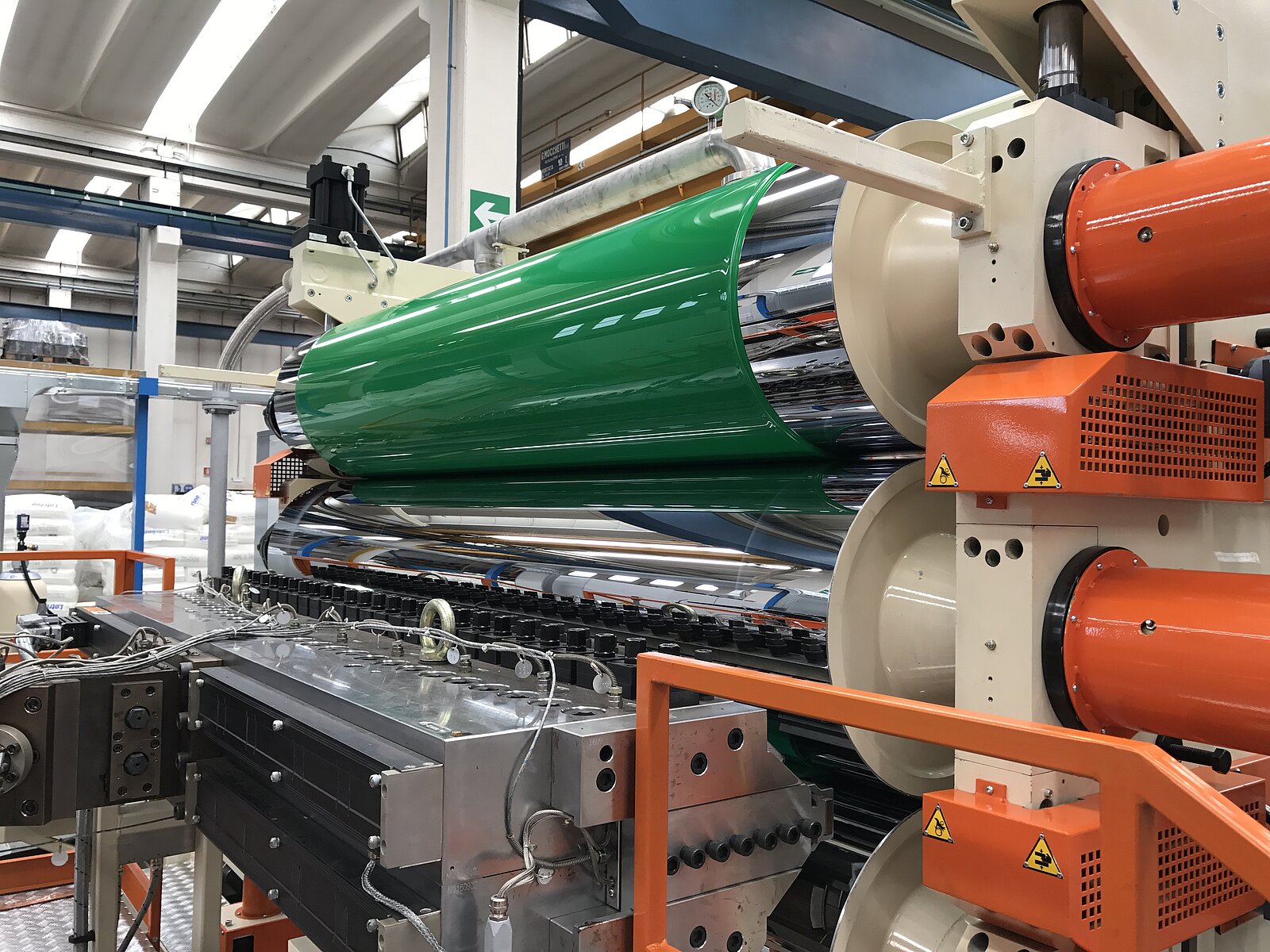

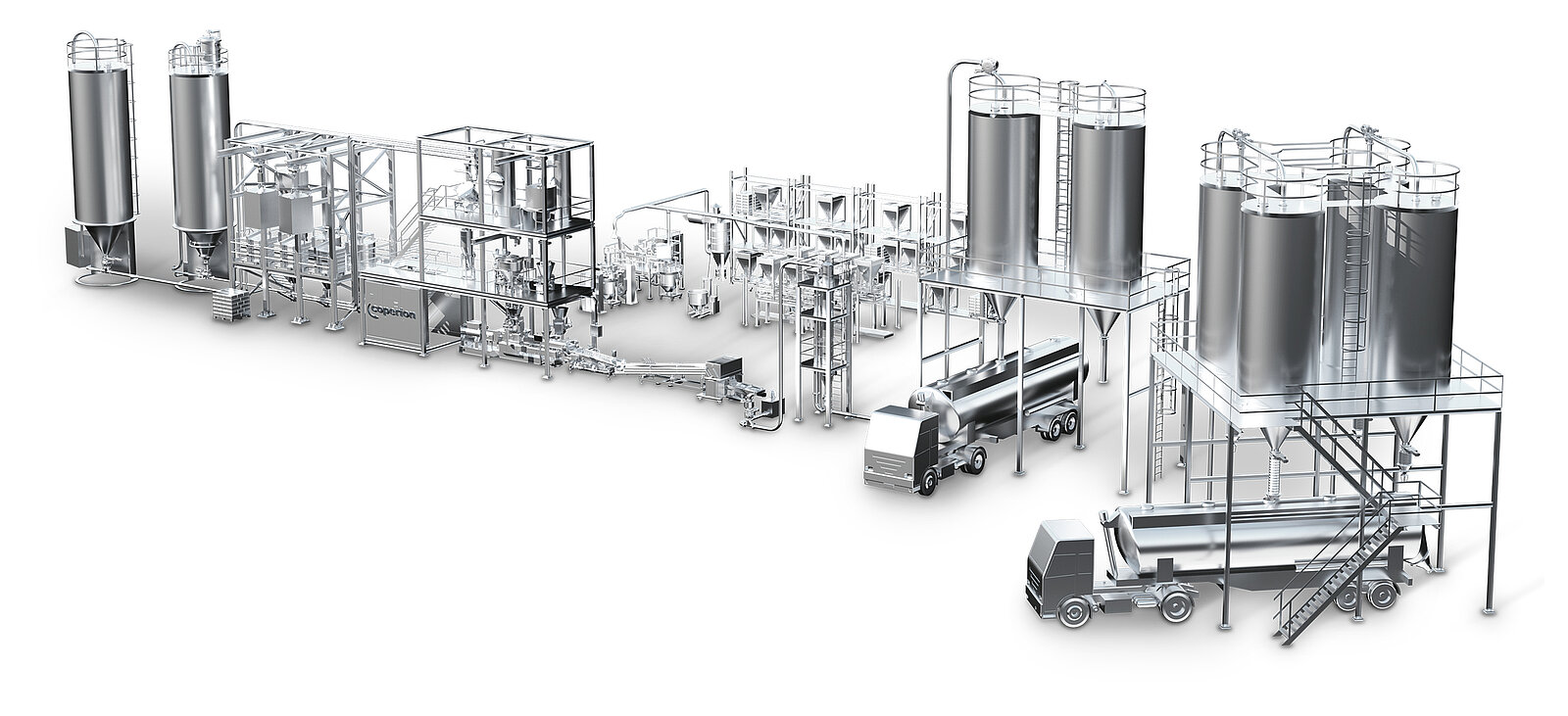

Recently, BG Plast took a significant step in strengthening its extrusion coating portfolio by delivering a state-of-the-art 3200 mm line to the Polish company MDM, a leading roof accessories manufacturer. Designed for the production of waterproofing membranes, this high-capacity system supports advanced coating and lamination processes tailored to the construction industry, including moisture barriers, roofing membranes, and drainage films.

“This plant represents a strategic achievement that confirms our extensive know-how in multilayer extrusion”, says Florio Roccon, owner of BG Plast.

Capable of handling a wide range of thermoplastics - including PVC, TPU, EVA, PP, TPO, and TPV - the line also supports flexible materials like nonwoven fabrics, carpets, and natural fibers.

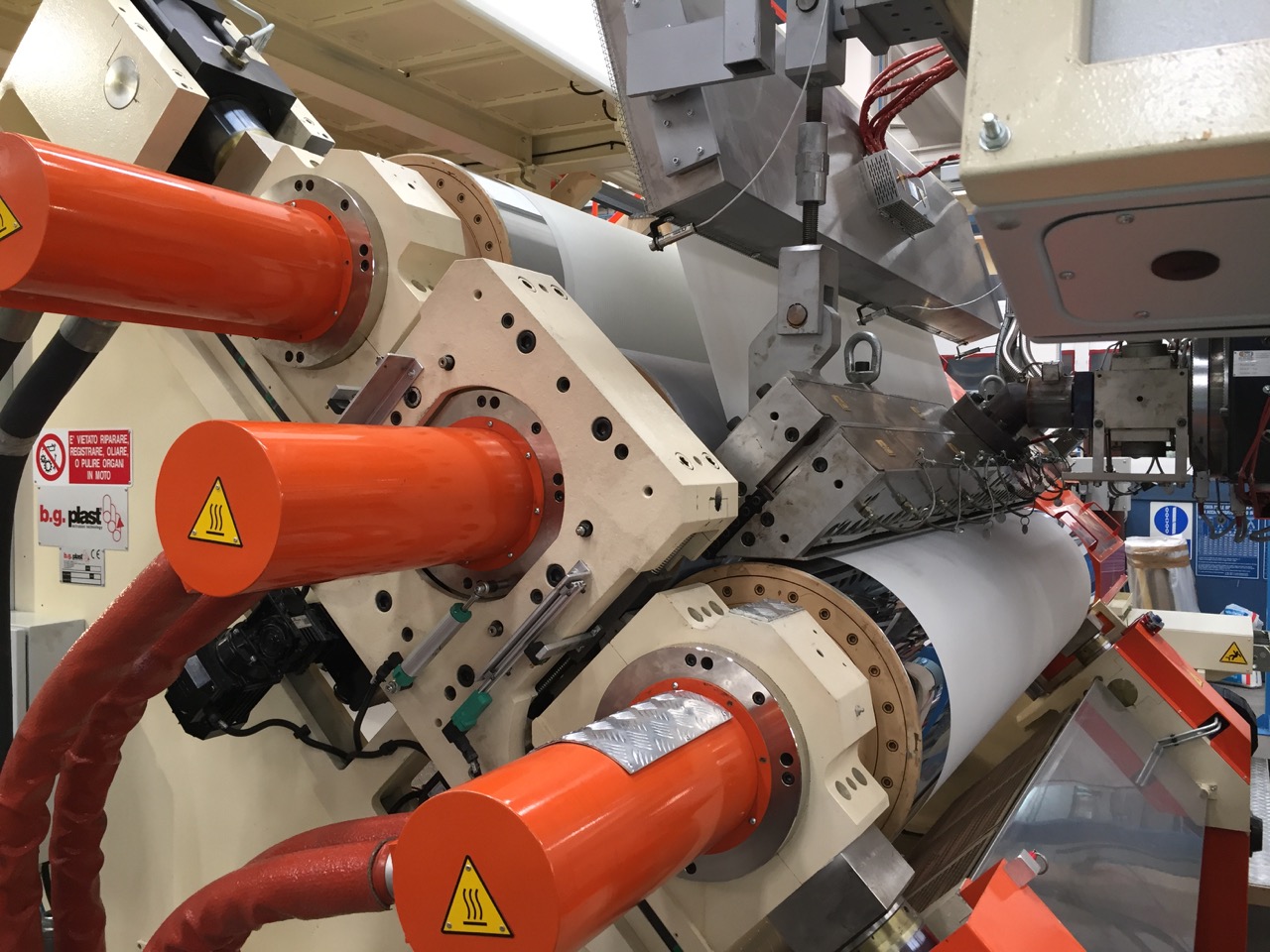

Key technical features of the line include:

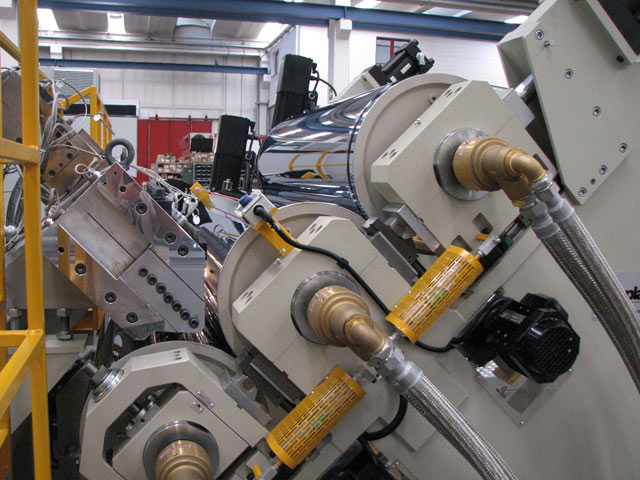

- High-efficiency single and twin-screw extruders with advanced degassing

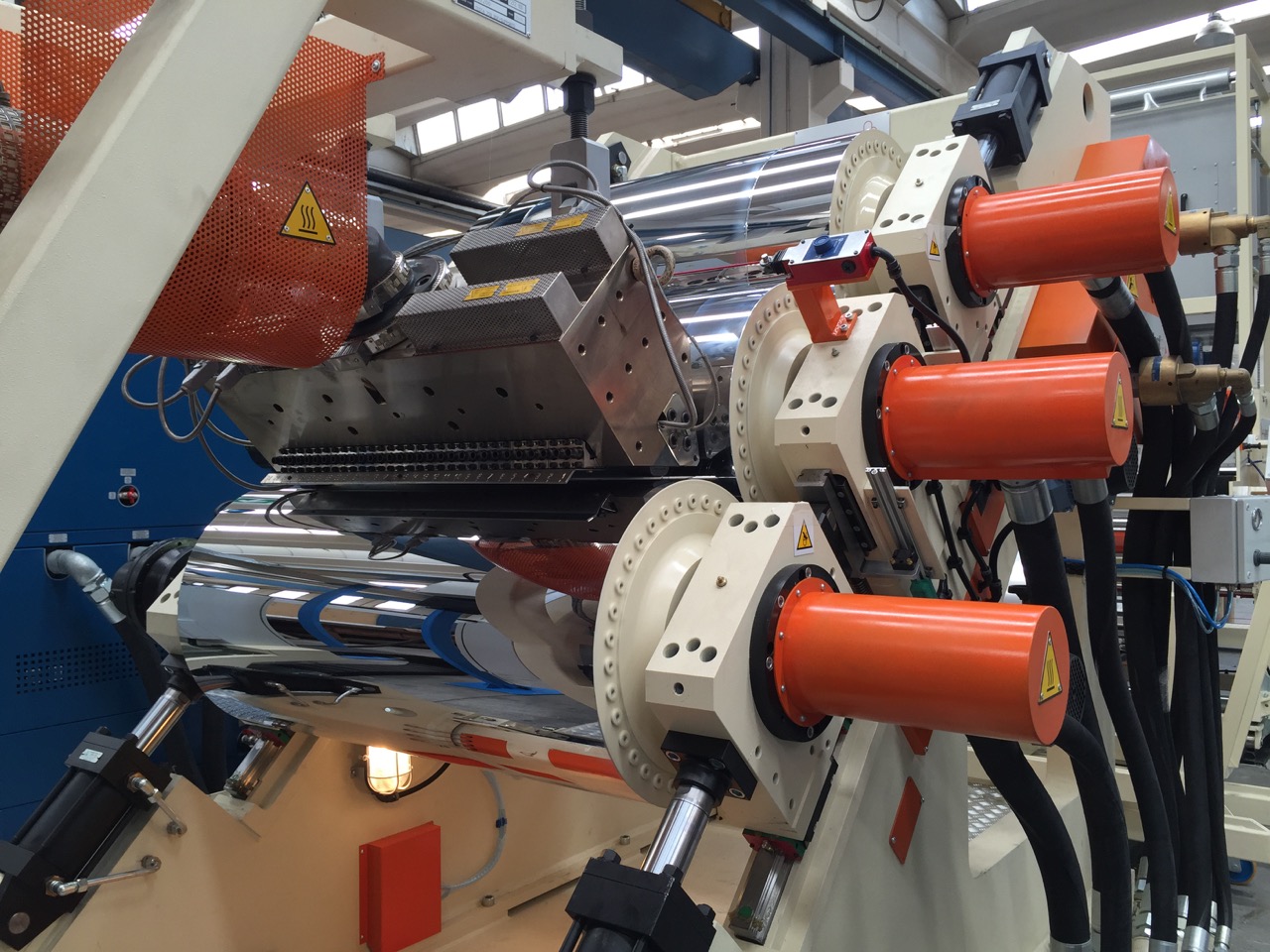

- Independent-roll calenders with forced-circulation thermal control

- “Cross-axis” micrometric thickness regulation for optimal flatness

- Flat dies up to 6000 mm for wide-format production

- Multi-layer configurations (up to 6 layers), combining polymers and supports such as nonwoven, carpet, or natural fibers.

This combination allows the production of coated and laminated composites with excellent adhesion, mechanical integrity, and consistent thickness, ideal for industrial-scale applications with stringent quality demands. The line’s flexible architecture ensures future integration of quality control modules and compatibility with recycled and sustainable materials.

Strategic partnership with Extech: an all-italian innovation synergy

Complementing this technological advancement, BG Plast has entered a strategic technical-commercial partnership with Extech srl, a fellow Italian firm based in Oleggio. Extech specializes in extrusion coating technologies for plastic films and tailor-made solutions for the flexible packaging sector. The collaboration aims to merge BG Plast’s engineering precision with Extech’s expertise in handling complex materials such as multilayer and barrier films.

“With Extech, we’ve built more than a partnership, we’re combining two sets of complementary expertise to develop next-generation coating systems that emphasize circular economy principles and high-value customization,” Roccon adds.

The two companies' engineering efforts will target extrusion coating lines optimized for multilayer lamination, surface treatments, and recycled content integration, to provide turnkey solutions for industrial and construction markets.

A reliable partner for customized, sustainable solutions in extrusion coating

The installation in Poland is a concrete example of BG Plast’s capability to meet the increasing demand for large-format, high-performance coating lines. Through this project and the Extech partnership, the company confirms its role as a reliable partner for customized and sustainable extrusion solutions.

For more information on BG Plast’s coating technologies and its full product range, visit www.bgplast.it.