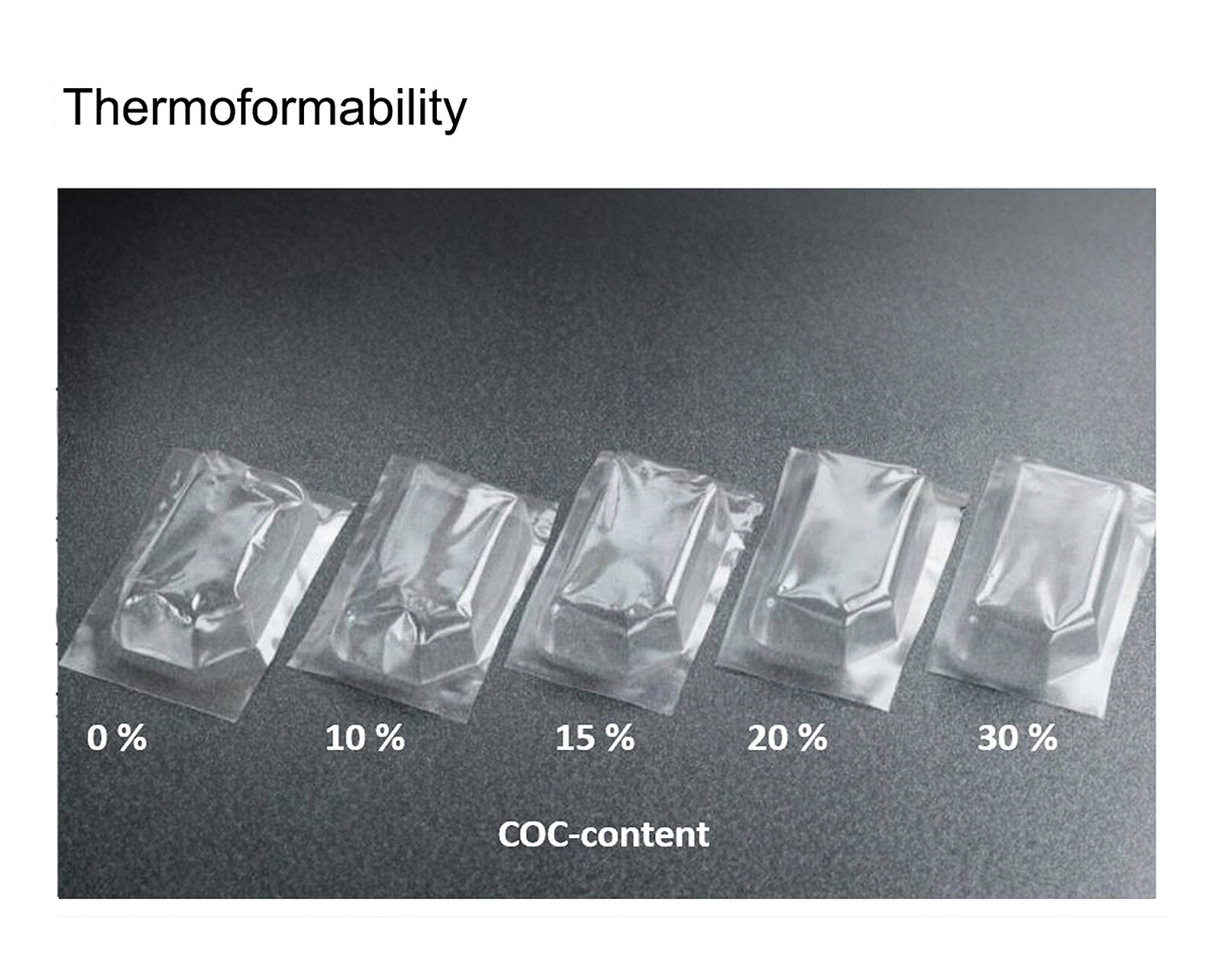

The implementation of the European Packaging and Packaging Waste Regulation PPWR requires the development of functionally optimized, recyclable packaging materials. Cycloolefin copolymers (COC), which are high-performance polyolefins that specifically control the material properties of polyethylene and polypropylene packaging by optimizing their stiffness, barrier, sealing properties and thermoformability, offer a promising solution.

Milestones in COC development

The development of the metallocene-based COC production process goes back to Hoechst AG and began in 1990 as part of a polymer research project. The basis for today's industrial process was laid in 1996 with a pilot plant. In 2000, Ticona put the production plant in Oberhausen into operation. Following the takeover of the COC business by Daicel and Polyplastics in 2006, TOPAS Advanced Polymers GmbH was founded. A new production line for cycloolefin copolymers will go into operation at the Leuna site in early 2026, marking a key step towards scaling up COC for industrial applications.

What is COC?

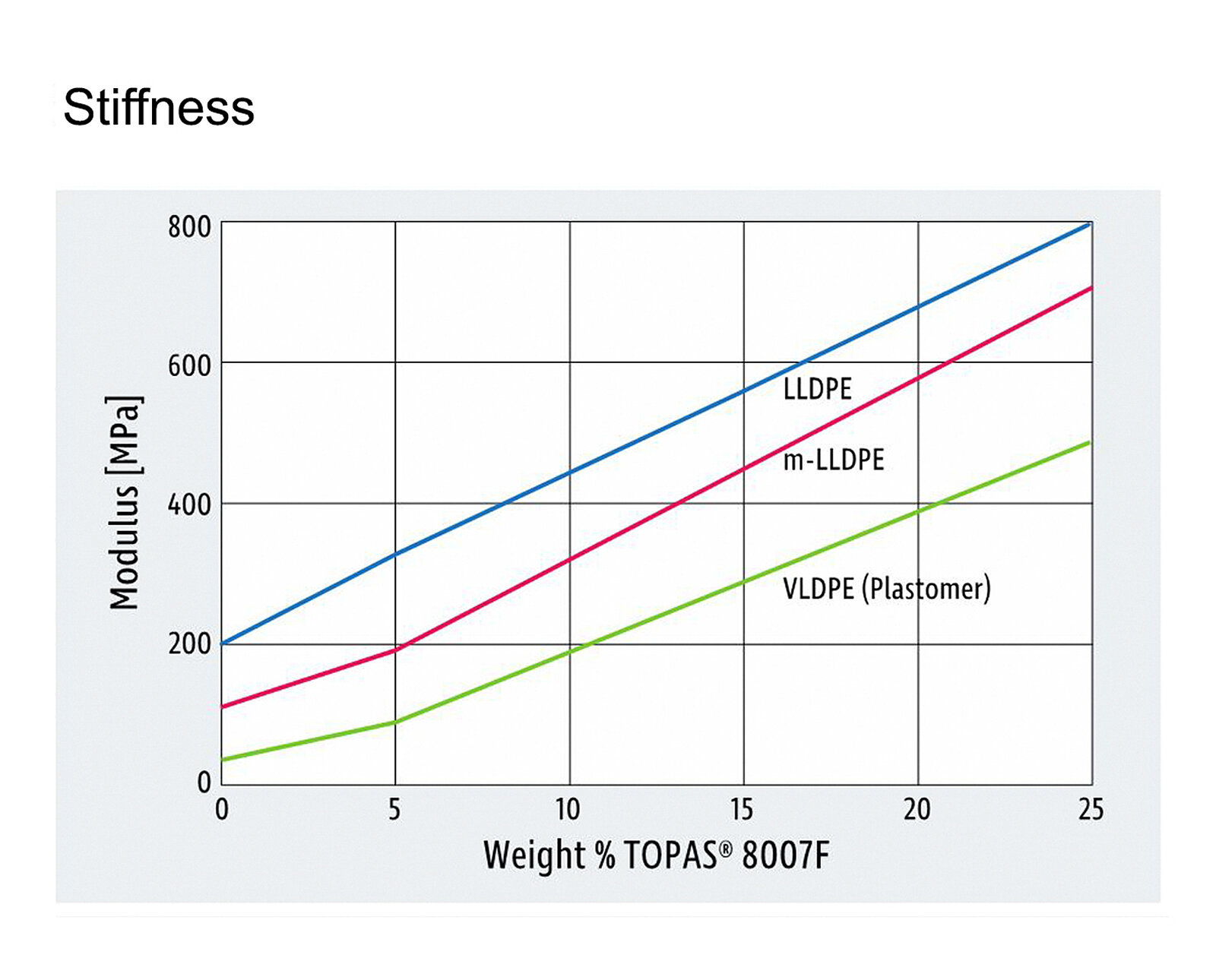

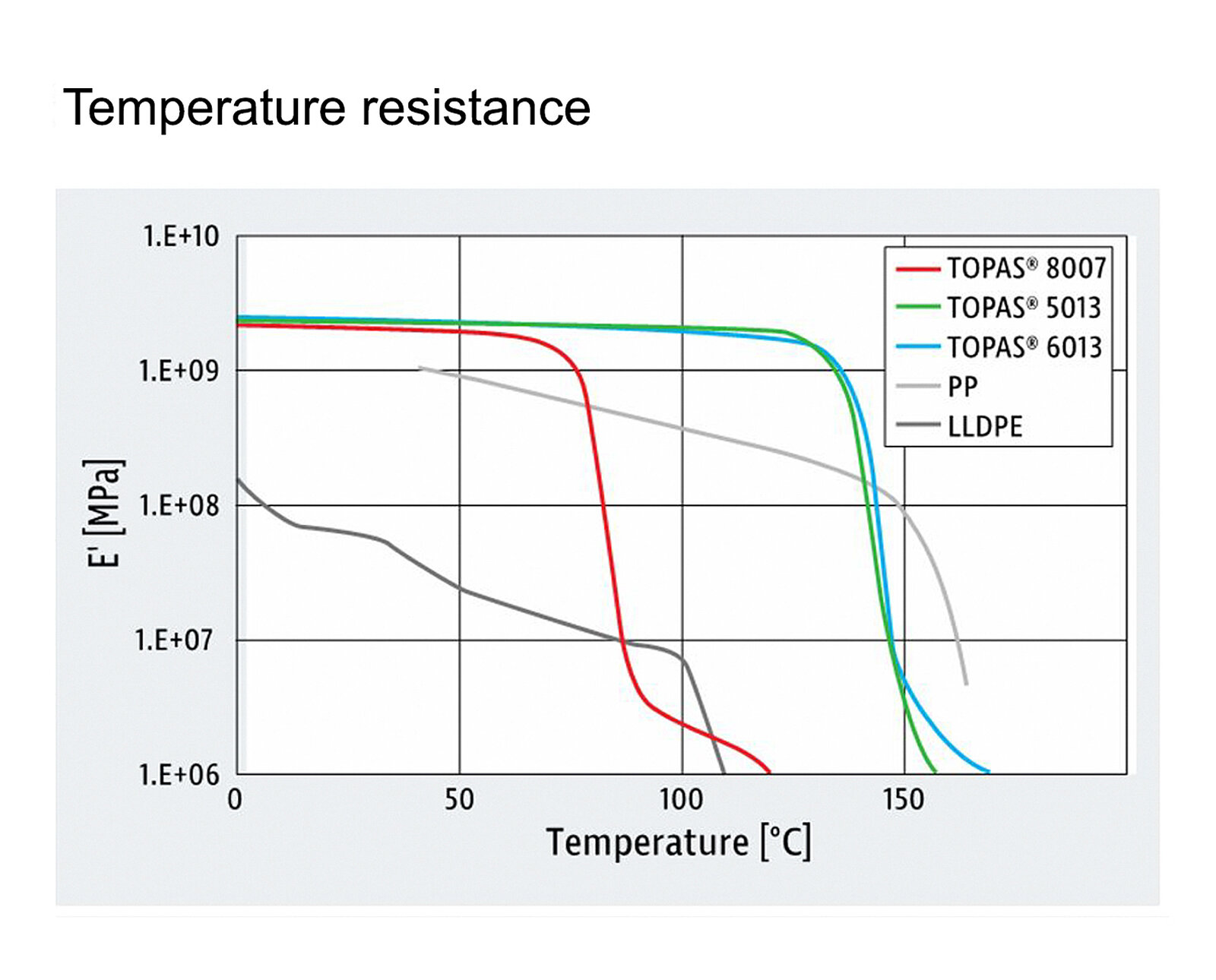

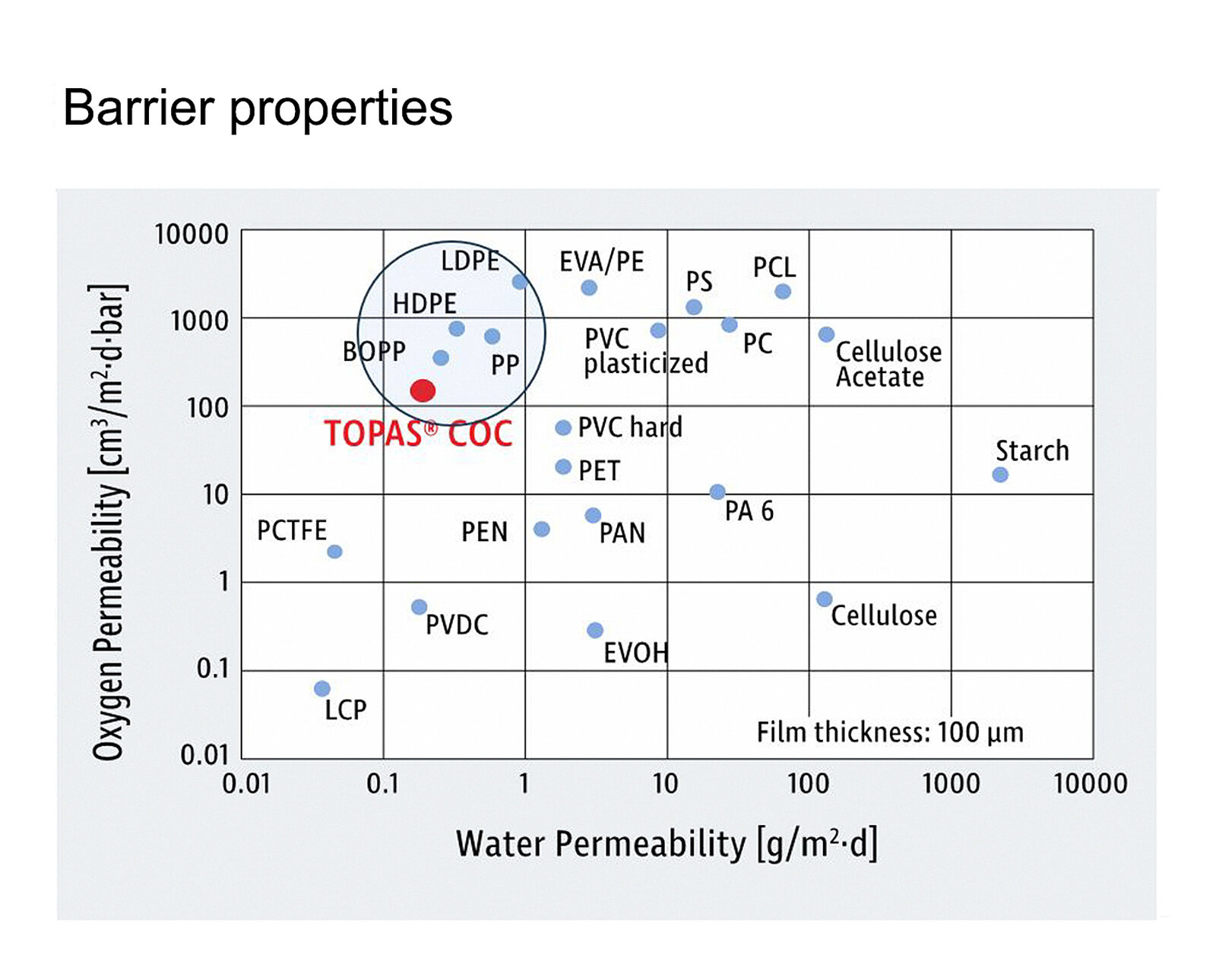

COCs are amorphous copolymers consisting of a cycloolefin (norbornene) and ethylene. Their properties can be varied by the ratio of these two monomers. The higher the proportion of norbornene, the higher the glass transition temperature (Tg), a key parameter for the thermal strength of a plastic. This allows heat deflection temperatures of up to 170 °C to be achieved. Due to the irregular incorporation of the norbonene into the polymer chain, COCs are amorphous and therefore crystal clear. They have a high stiffness of up to 3,200 MPa and offer an excellent water vapor barrier. COCs are compatible with the standard polyolefins polyethylene (PE) and polypropylene (PP), which makes them recyclable in this circuit.

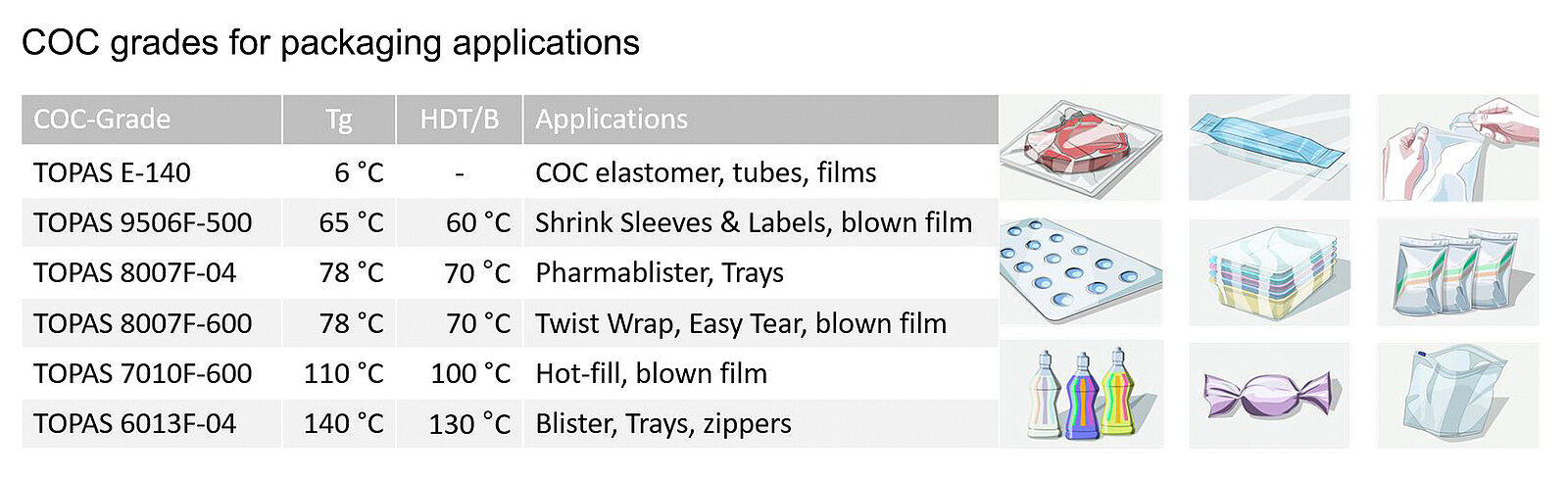

Systematics and variety of types

TOPAS offers a wide range of COC grades for different packaging applications. In addition to the molecular weight, the glass transition temperature (Tg) is decisive for the properties and therefore for the application.

![[Translate to English:] [Translate to English:]](/fileadmin/redakteur/Kunden/Topas/2025/2025-06-26/Header_1200x435px.jpeg)