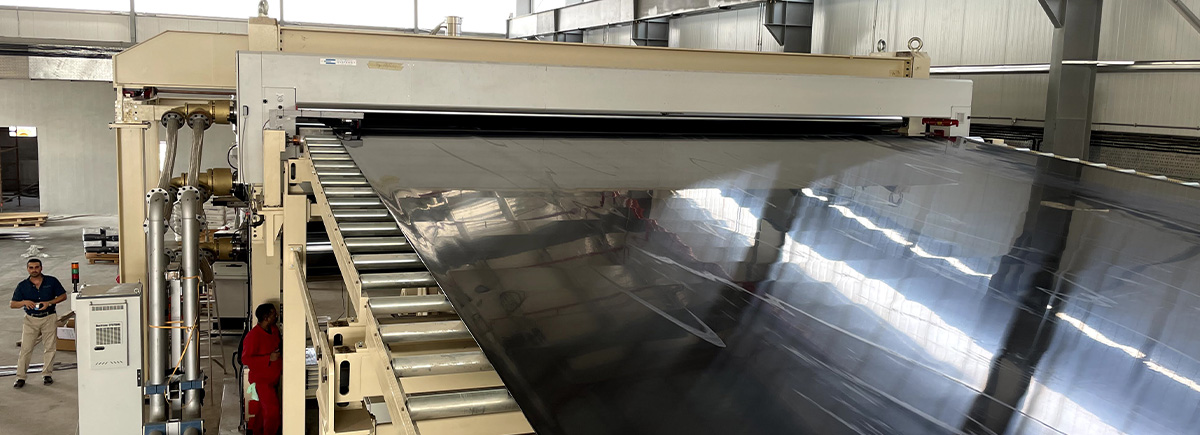

HDPE, LDPE, and PP geomembranes are fundamental elements for waterproofing in environmental, infrastructural, and industrial applications. To meet the needs of a market increasingly oriented towards high-performance solutions with low environmental impact, BG Plast has developed highly customizable extrusion and calendering lines capable of producing smooth or structured geomembranes, also coupled with geotextiles, with widths up to 8000 mm after trimming and thicknesses from 1 to 3 mm.

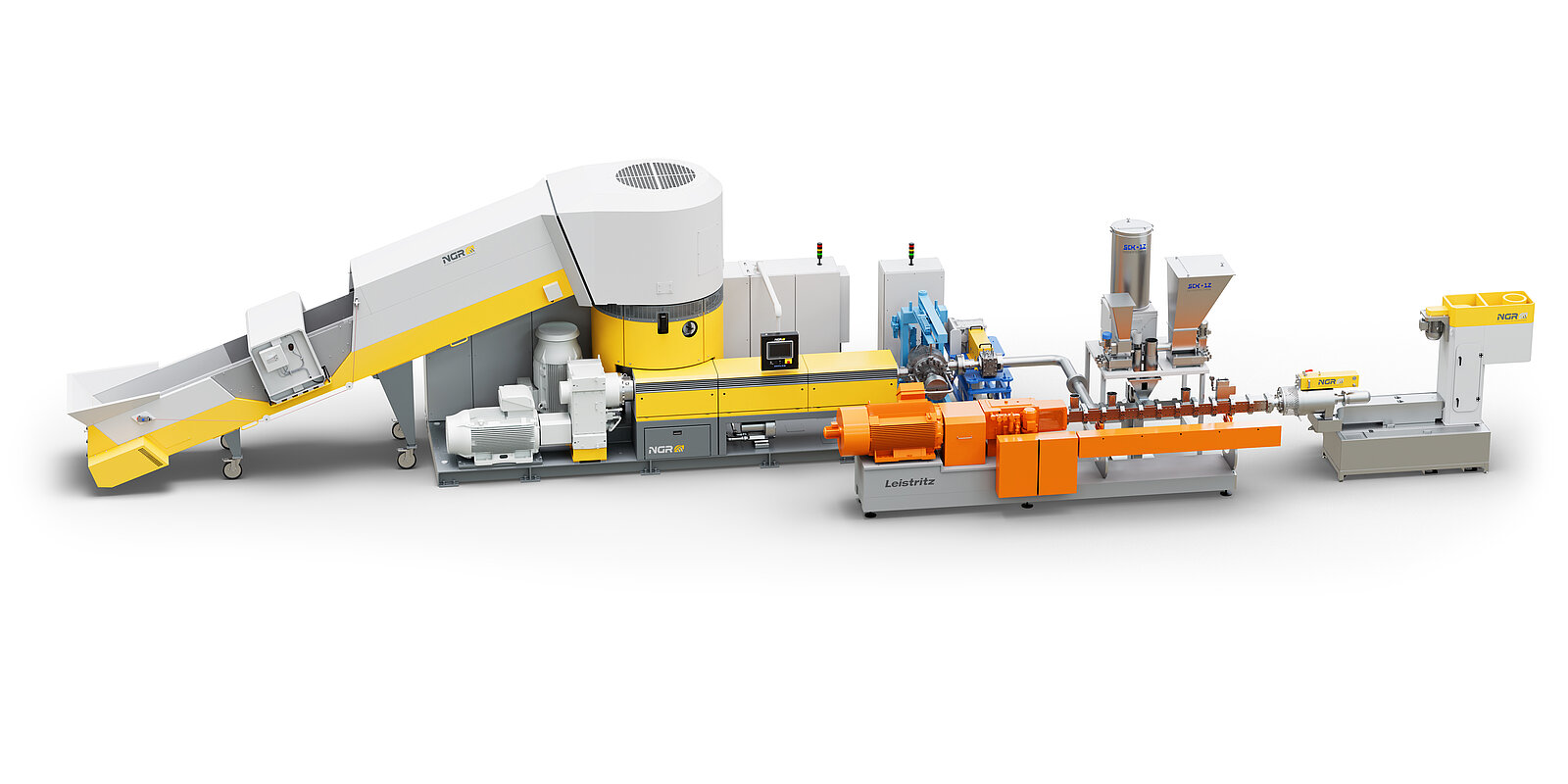

“Today, our geomembrane plants can achieve productivity of up to 1500 kg/h, with impeccable extrusion quality even with complex materials and multilayer configurations,” explains Florio Roccon, owner of the company based in the province of Varese. “We designed these lines with maximum production flexibility and ease of integration with the welding and storage systems used on large-scale construction sites in mind.”

Technical performance at the service of major projects

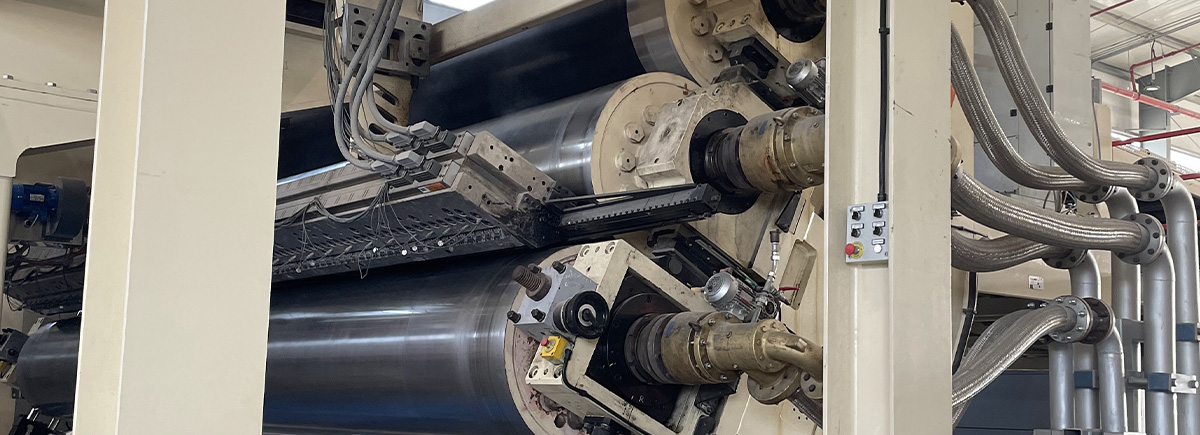

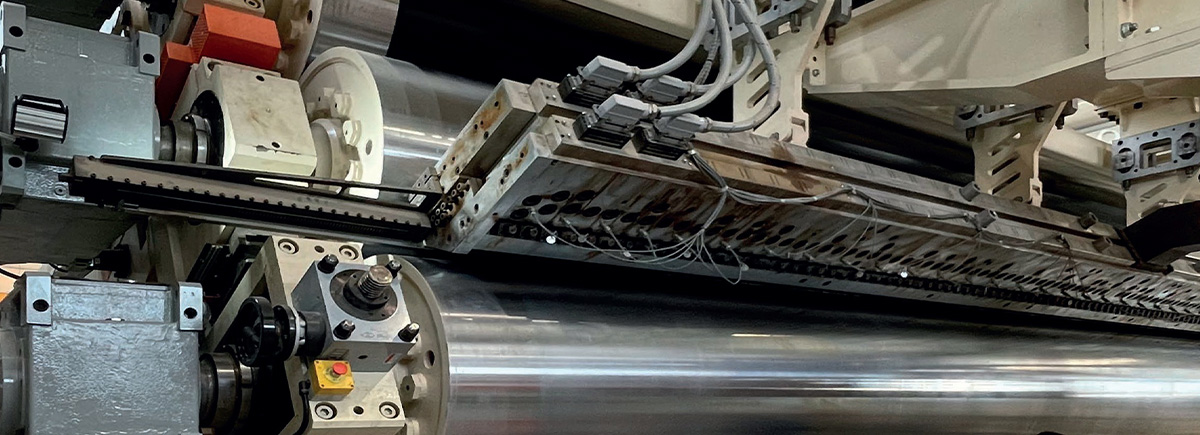

BG Plast lines for geomembranes allow the coextrusion of multiple layers, with the possibility of direct lamination with geotextiles and the use of different polyolefin formulations, such as HDPE, LDPE, and PP. The membranes can be made with a smooth or structured (nip) surface, depending on the final application. The heart of the system is a high-pressure calender with precision electromechanical control and independent temperature control systems, which guarantee uniform thickness even over large widths.

“We produce solutions for customers operating in strategic areas: from waste management to hydraulic works, from soil protection in agricultural basins to structures for the mining sector,” adds Roccon. “This is why our lines must be extremely reliable, modular, and capable of processing technical materials without compromise. Our technology also minimizes waste for greater efficiency and reliability over time thanks to the quality of the calendering process.”

Areas of application and long-term reliability

Thanks to high resistance to chemicals, UV rays, and temperature changes, geomembranes manufactured using BG Plast systems are used in numerous sectors:

- Landfills, for the safe containment of leachate and industrial waste

- Water treatment plants, for waterproof linings of basins and tanks

- Hydraulic infrastructure such as canals, tunnels, and artificial lakes

- Agriculture, for storage basins and soil protection

- Mining industry, for the containment of sludge and process liquids.

To explore these and other application scenarios in depth, industry professionals can meet the BG Plast team at K2025 – Düsseldorf, 8–15 October – Hall 16 / Stand D61, where engineers will be available to present the latest technologies for every need.

Custom-made engineering for every need

Each line is developed in synergy with the customer, with tailor-made configurations ranging from cylinder geometry to the number of extruders for co-extrusion. “We do not offer standardized solutions, but systems built around a concrete production project and its specificities,” emphasizes Roccon. “Our goal is to support the customer with technical expertise and industrial vision.”

With over 35 years of experience, BG Plast continues to stand out in the European extrusion landscape thanks to its agile, innovative, and entirely Made in Italy structure.