At K 2025 in Düsseldorf (October 8–15, Hall 16, Stand D61), BG Plast will unveil SAGEC, a breakthrough extrusion system engineered not simply as a machine, but as a new concept of production. With this patented technology, BG Plast invites the industry to look beyond traditional performance metrics and imagine what extrusion can become: adaptive, sustainable, and visionary.

“Innovation should not only solve today’s problems, but anticipate tomorrow’s challenges,” says Florio Roccon, owner of BG Plast. “SAGEC embodies that philosophy: a system that transforms thermoplastic processing into a platform for efficiency, sustainability, and also creativity.”

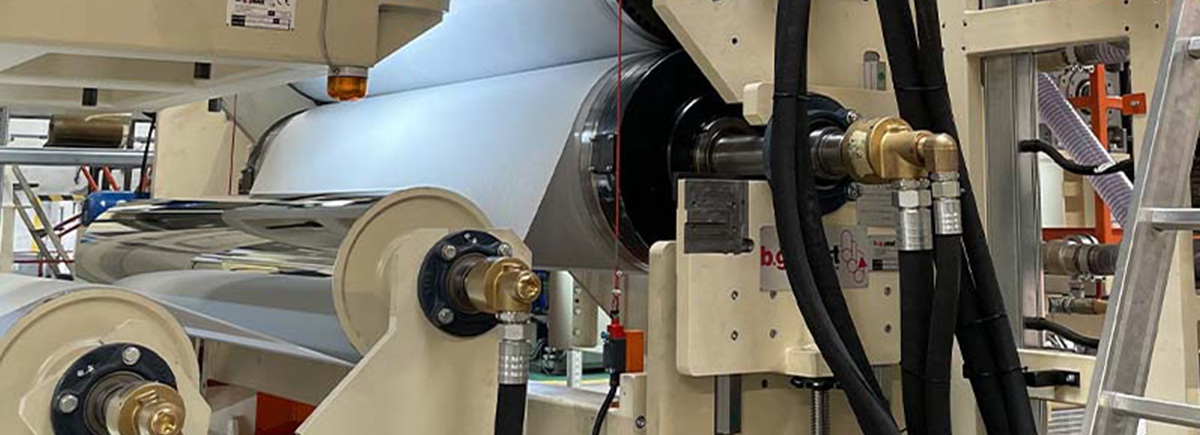

A new paradigm in multilayer bubble board production

SAGEC is more than a line: it is a paradigm shift. To produce multilayer bubble boards in a single step, it integrates a unique calendering design, with the possibility of exploring different geometries for the inner core. This flexibility allows manufacturers to create solutions that did not exist before: lightweight yet robust, functional yet sustainable.

The boards deliver qualities that align with the future of materials:

- Lightweight for easier handling and logistics

- High strength in both machine (MD) and cross directions (CD)

- Excellent flexural and compression resistance

- 100% recyclable and food-approved

- Water- and moisture-resistant, washable, and durable

- Thermal and acoustic insulation

- Shockproof, printable, and easily laminated with films, nonwovens, or carpets.

With thicknesses from 4 to 12 mm, widths up to 2,300 mm, and production capacities reaching 1,300 kg/h, SAGEC bridges high output with limitless versatility.

Sustainability as an engine of innovation

For BG Plast, sustainability is not a constraint but a driver of progress. SAGEC is engineered to minimize energy consumption and reduce waste, while producing fully recyclable boards. In doing so, it empowers manufacturers to embrace circular economy principles without ever compromising on productivity.

“As industries worldwide transition toward greener models, technology must lead the way,” Roccon explains. “SAGEC is our answer: proof that advanced engineering and environmental responsibility can - and must - evolve together.”

A laboratory for the future: driving innovation together

BG Plast’s commitment extends beyond delivering machines. At its headquarters, the company operates a fully functional SAGEC prototype, a laboratory where new geometries and applications can be tested in partnership with clients. This collaborative approach embodies BG Plast’s vision: building not just equipment, but shared pathways to innovation.

From Düsseldorf to the world

K 2025 offers the stage to showcase SAGEC, but the ambition goes far beyond. For BG Plast, the system represents a starting point for a broader journey: redefining how extrusion can serve industries in transformation - from packaging to automotive to construction - with solutions that are lighter, stronger, and more responsible.

“Every breakthrough starts with a question,” Roccon concludes. “With SAGEC, we asked: what if extrusion could be reimagined? At K 2025, we present our answer.”