For BG Plast, K 2025 was not only a success, but also a milestone that marked fifty years of participation in the world’s leading plastics and rubber trade fair. Since 1975, Florio Roccon, founder and CEO of BG Plast, has attended all 17 editions of the event. This “golden anniversary” celebrated half a century of continuous innovation, research, and collaboration with the global extrusion community.

“Every K is a story in itself,” said Roccon. “But this one felt special. We have seen how the plastics industry is evolving into something truly green, smart and responsible, where engineering drives real sustainability.”

A fair that reaffirms the strength of the industry

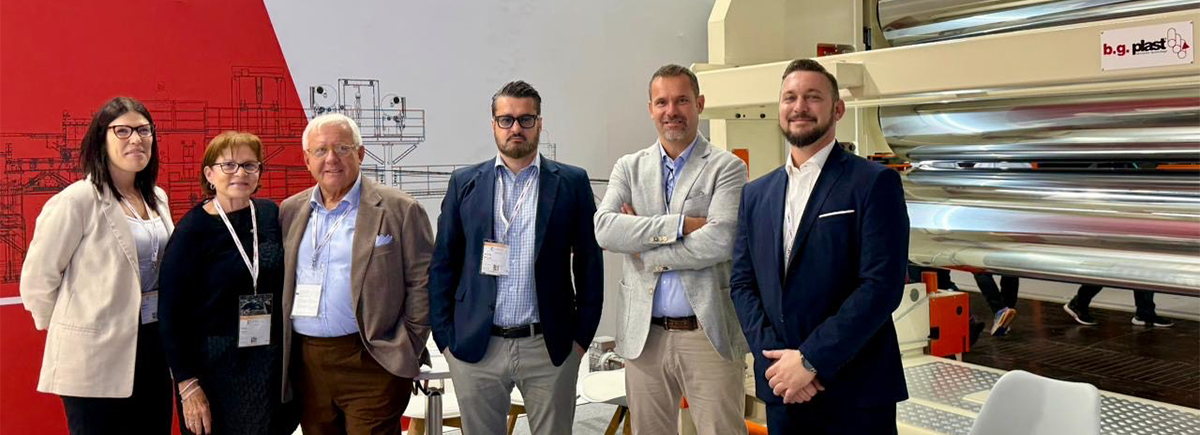

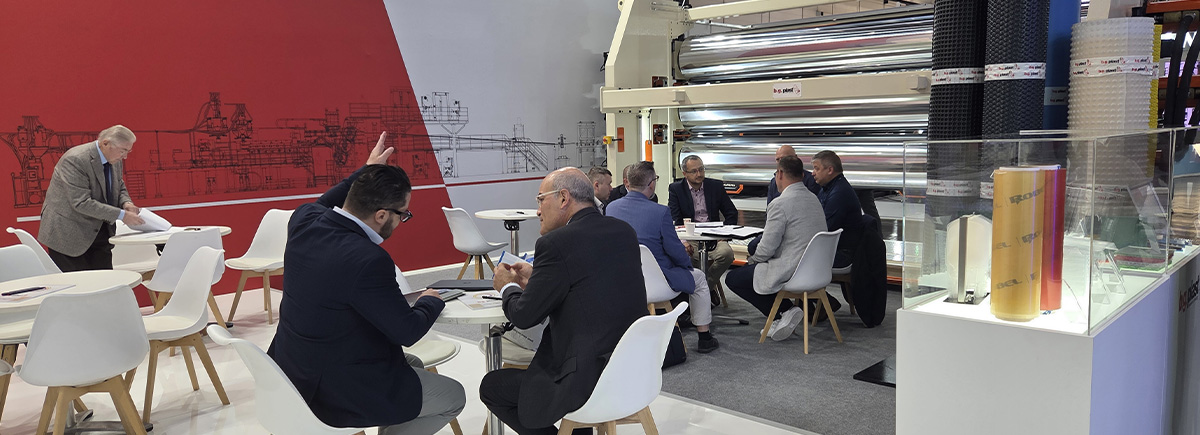

K 2025 brought together exhibitors and professionals from all over the world. Within this vibrant international context, BG Plast’s booth stood out as one of the most visited in the extrusion and calendering section, drawing engineers, decision-makers and project developers from Europe, Asia and the Americas.

The Italian company showcased an impressive lineup of technologies, designed to combine precision, flexibility and sustainability: the SAGEC system, the 4500 mm calender, and new lines for geomembranes and extrusion coating.

Technology and performance on display

The patented SAGEC system was among the highlights of BG Plast’s stand. Designed for the extrusion of multilayer bubble panels in a single step, it drew strong interest for its ability to produce lightweight, highly resistant, and fully recyclable sheets. Many visitors from the automotive and construction industries praised its potential for structural and thermo-acoustic panels.

The new 4500 mm calender was admired for its engineering precision and large-scale capabilities. Processing PP, PET, PS, ABS and PVC, it ensures dimensional accuracy and excellent surface finish on wide sheets and geomembranes. Visitors appreciated its modular architecture and ease of integration with complex extrusion setups.

Complementing these systems, BG Plast also presented its latest geomembrane and extrusion coating lines, engineered for environmental and industrial applications. These lines, with widths up to 8000 mm and productivity up to 1500 kg/h, impressed attendees from the construction and infrastructure sectors for their performance and adaptability to recycled and biobased materials.

Positive feedback and international engagement

Throughout the fair, BG Plast’s stand served as a meeting point for long-time customers and new partners seeking tailor-made extrusion solutions. Discussions focused on process optimization, circular economy principles and energy efficiency.

“For us, sustainability is not a trend,” Roccon noted. “It’s the outcome of well-designed technology that grows with the customer and reduces impact without compromising quality.”

Looking ahead

K 2025 reaffirmed BG Plast’s position as a reliable and forward-thinking partner in the global thermoplastics industry for high-precision extrusion and calendering equipment.

“The enthusiasm we saw this year is a great signal,” concluded Roccon. “It shows that the drive to innovate remains as strong as ever. That’s what motivates us to keep building the future of extrusion.”

BG Plast looks forward to continuing this journey of innovation and collaboration and to meeting the industry again at the next K 2028.