In an increasingly demanding packaging market, extrusion coating on paper is a strategic technology to combine performance, sustainability and production efficiency. BG Plast, the Italian specialist in extrusion and calendering plants for thermoplastic materials, is strengthening its position in this field with complete, tailor-made extrusion coating and laminating lines engineered for advanced paper and paperboard applications.

Extrusion coating consists of applying a thin layer of molten polymer directly onto a paper substrate, to create a high-performance composite material. By combining the structural strength of cellulose fibers with the functional properties of thermoplastics, paper becomes moisture-resistant, greaseproof, heat-sealable and more mechanically stable, while remaining lightweight, printable and suitable for downstream converting processes.

“For us, extrusion coating on paper is a way to rethink packaging performance from the inside out,” says Florio Roccon, Owner of BG Plast. “The goal is to enhance paper with the minimum amount of polymer necessary, achieving maximum functional value with optimized material use.”

From process engineering to high-performance multilayers

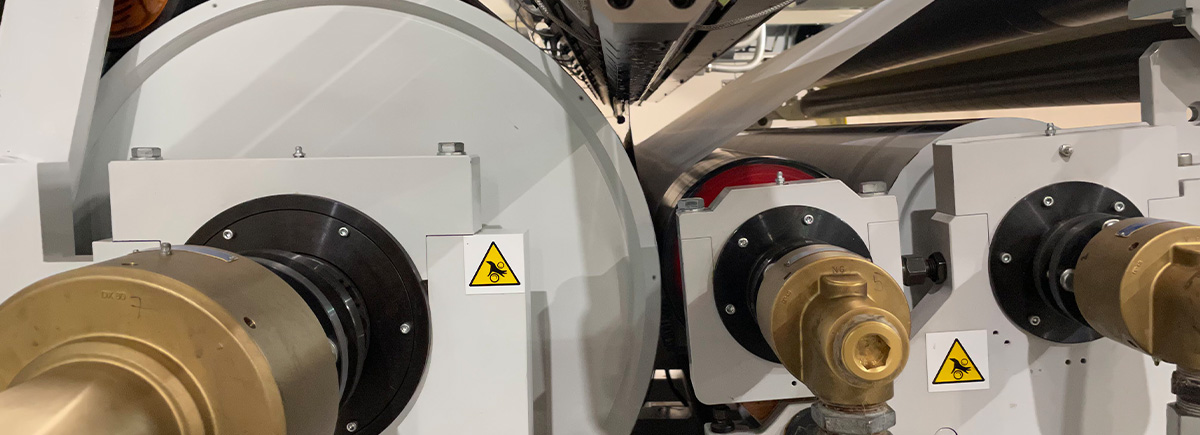

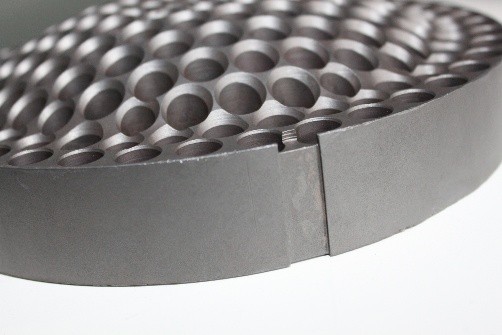

In BG Plast extrusion coating lines, polymers such as LDPE, LLDPE, HDPE, EVA, EVOH, Surlyn, TPU or CPP are melted in high-performance single-screw extruders and distributed evenly through accurate T-dies onto a continuous paper or board substrate. Controlled pressure, optimized temperature profiles and chrome-plated cooling rolls provide stable adhesion and uniform thickness.

The coated substrate then passes through a lamination and calendering group - the heart of the line - where temperature uniformity, controlled cooling and adjustable nip pressure guarantee surface quality and consistent bonding.

Depending on the application, extrusion coating can be integrated with extrusion lamination, where the molten polymer acts as a thermal bonding layer to create advanced multilayer “sandwich” structures without the use of solvents or chemical adhesives.

Applications: from beverage cartons to technical packaging

BG Plast lines support a wide range of paper-based packaging solutions, including beverage cartons for milk, juice and wine, aseptic packaging, coated paper cups and flexible food packaging for snacks, ready meals and frozen products. Barrier properties can be enhanced with materials such as EVOH to reduce oxygen permeability and extend shelf life.

Beyond food packaging, extrusion-coated paper is increasingly used in medical, pharmaceutical and industrial applications, where moisture protection, mechanical resistance and controlled sealing performance are essential.

A complete industrial approach

Each project starts with an in-depth technical analysis of materials, production targets and end-use requirements. The company designs and manufactures complete lines including extruders (up to 1,100 kg/h output), T-dies with manual or automatic adjustment, lamination units with high-efficiency thermal exchange, unwinders and winders (up to 500 m/min), and integrated surface treatment systems such as corona, plasma or flame treatment.

“Our strength lies in process control and reliability,” Roccon adds. “Customers need constant quality, production continuity and scalability. That is what we engineer into every extrusion coating line.”

With its modular and flexible configurations - single-layer, 3-layer and 6-layer - BG Plast enables converters and packaging manufacturers to develop competitive, sustainable and technically advanced paper-based solutions.

![[Translate to English:] [Translate to English:]](/fileadmin/redakteur/Kunden/IBD_Wickeltechnik/News/2026/2026-02-06/2026-02-11.jpeg)